- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- vacuum processes

Results for

Vacuum processes - Import export

BORNEMANN GMBH

Germany

The aluminium front panel displayed was printed with texts using the vacuum process. The milled recesses are delivered on special CNC milling machines to customer specification. On the rear of the panel, threaded bolts made from stainless steel and earthing screws can be pressed in. Contact I have read and agree to the privacy policy. *Pflichtfelder

Request for a quote

KEIPER GMBH & CO. KG ANTRIEBS- U. TRANSPORTTECHNIK

Germany

Keiper haul-off timing belts are made with polyurethane or neoprene timing belts that are finished with many different kinds of coatings. They are used for conveying foils in bag forming, filling and sealing machines as well as numerous other conveying tasks. The extensive range of designs offers the optimal solution for any transport task and application, e.g. with smooth or vacuum-processed surface, finished according to individual specifications, and with many different coatings. Timing belts - Polyurethane molded timing belts - or neoprene molded timing belts Tension cords - Steel - Aramid - Polyester Coatings - PU yellow - Linatex - Various elastomers - Silicone

Request for a quote

KIRSCH KUNSTSTOFFTECHNIK GMBH

Germany

The vacuum forming process, implemented with simple tools, is ideal for three-dimensional shaping. In modern thermoforming machines with a table size of 1000 x 660 mm up to 2000 x 1200 mm, both negative and positive moulds can be used. Furthermore, we can process the components with our 5-axle-milling-machines afterwards.

Request for a quote

MOOG GAT GMBH

Germany

Rotoguide: Micro-jet technology with air bearings from ROTOGUIDE stands for ultimate accuracy, load-bearing capacity and robustness. Shafts and bearing parts are machined to ultra-high precision for a positioning accuracy within µm range. ROTOGUIDE units are especially suitable for highly accurate linear and rotational motion under ultra-high vacuum and for all processes with ultimate demands in terms of cleanliness and accuracy

Request for a quote

ALWA TECHNISCHE PRODUKTE FÜR KUNSTSTOFFVERARBEITUNG, MODELL UND FORMBAU GMBH

Germany

ALWA POR is porous and has a smooth surface structure. The product is characterized by a high stability, pressure-resistance and a long-term heat resistance of over 190°C. It is especially suitable for moulds with fine and complex structures. The good air permeability leads to a uniform stretching of the foil in the process of thermoforming. With this innovative product the annoying drilling of vacuum holes becomes obsolete and thus no visible markings are left on the thermoformed foil. Larger dimensions can be achieved by screw connections. Longer and wider dimensions by gluing. ALWA POR is easily machinable: Sawing, drilling, grinding, polishing. It also remains porous after polishing. ALWA POR is especially suitable for vacuum thermoforming and vacuum forming and is additionally suitable for - aeration of aquaria, fishponds and sewage treatment plants, - venting of injection moulds and blow moulds, - any proceedings of hot steam or water steam processing, - vacuum clamping

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

SolarPaq® temperature profiling systems are designed for specific use in solar photovoltaic (PV) manufacturing. These systems, consisting of user-friendly Insight™ software, Datapaq® Q18 data loggers, stainless steel thermal barriers, thermocouples with PTFE or mineral insulation and accessories, provide you with the tools required to obtain the highest production yields. The Datapaq Q18 logger features rugged, reliable and accurate data acquisition circuits, clear status indicators and an intelligent battery management system. It also features start/stop buttons, time or temperature trigger, memory capacity of 300,000 readings and measures wide temperature ranges from -200°C to 1370°C/-328°F to 2498°F. SolarPaq Profiling System for CiGs Panel Coating SolarPaq temperature profiling system for CiGs Panel Coating monitors the glass substrate as it passes through the vacuum coating process. Its core, the DQ1840 datalogger, is housed

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

The Controlled Atmosphere Brazing (CAB) and Vacuum Furnace Tracker Systems from Fluke Process Instruments feature the Datapaq TP6 data logger, a reflective or sealed for CAB thermal barrier, thermocouples and our intuitive Insight™ Software to create a complete solution. The CAB Furnace Tracker Systems featuring the TB4000 & TB4002 thermal barriers operate in environments up to 800°C (1472°F) and are designed for frequent use in the aggressive atmosphere present in this process. The Vacuum Brazing Furnace Tracker Systems, which include the VB1150 & VB1151 thermal barriers, make use of reflective plate technology to eliminate the need for insulation and ensure that out-gassing from the system is minimized so production is not disrupted when profiling. Both systems can be used to conduct temperature uniformity surveys (TUS) in compliance with CQI 29. Data Logger The Datapaq TP6 is the perfect solution for the most demanding high-temperature profiling applications

Request for a quote

EMPIRE MEUBEL

Netherlands

This practical vacuum chamber with pump is an ideal choice for degassing operations, vacuum encapsulation, etc. High-quality material: The stainless steel material ensures that the vacuum tool can withstand wear and pressure. Better view: The clear acrylic lid does not bend during vacuum operations, allowing a better view of the entire degassing process. The oil vacuum gauge and shockproof vacuum gauge provide better control. Reliable Degassing: The degassing chamber is tightly sealed to prevent leaks and provide a safe, reliable means of degassing. Wide Application Range: The unit comes with a 3.5 CFM vacuum pump and a superior quality 3.7 L vacuum chamber. It is suitable for refrigeration repairs, vacuum packing and other extraction operations.

Request for a quote

BDSENSORS GMBH

Germany

The precision pressure transmitter DMP 331Pi demonstrates the further development of well-tried industrial pressure transmitter DMP 331P. The signal from the specially designed piezoresistive stainless steel sensor is processed by the newly developed digital electronic system, performing thus an active compensation of sensor-specific deviations such as hysteresis, thermal errors and non-linearity. The temperature field of application of -40 ... 125 °C can be extended by the integration of a cooling element up to 300 °C. Features: — nominal pressure: 0 ... 400 mbar to 0 ... 40 bar — accuracy: 0.1 % FSO — excellent temperature response 0.04 % FSO / 10K (≤ 0.04 % FSO / 10K) — hygenic version — vacuum resistant — processing of the sensor signal using digital electronics Optional Features: — IS-Version Ex ia = intrinsically safe for gases and dusts

Request for a quote

ET TAMBURU DONER TEKNIK

Turkey

It has vaccum system for seasoning penetrate meat and meat turn more flavour. Endurable design,quality working and structure of steinless steel .besides it has plc system. You can configure how it works. meat tumbler mixer meat tumblers for sale meat tumbler ebay meat tumbler for sale south africa meat tumbler reviews meat tumbler recipes tumblr meat processing vacuum meat tumbler canada commercial meat tumbler what does a meat tumbler do how to build a meat tumbler biro meat tumbler meat tumbler canada meat compost tumbler countertop meat tumbler cabela's meat tumbler challenger meat tumbler diy meat tumbler electric meat tumbler vacuum meat tumbler for sale vacuum tumbler for meat processing meat tumbler ham hobart meat tumbler industrial meat tumbler lance meat tumbler meat vacuum tumbler manufacturers meat tumbler for sale philippines tumblr meat smoker meat tumbler for sale small meat tumbler stx meat tumbler meat tenderizer tumbler

Request for a quote

ET TAMBURU DONER TEKNIK

Turkey

It has vaccum system for seasoning penetrate meat and meat turn more flavour. Endurable design,quality working and structure of steinless steel .besides it has plc system. You can configure how it works. meat tumbler mixer meat tumblers for sale meat tumbler ebay meat tumbler for sale south africa meat tumbler reviews meat tumbler recipes tumblr meat processing vacuum meat tumbler canada commercial meat tumbler what does a meat tumbler do how to build a meat tumbler biro meat tumbler meat tumbler canada meat compost tumbler countertop meat tumbler cabela's meat tumbler challenger meat tumbler diy meat tumbler electric meat tumbler vacuum meat tumbler for sale vacuum tumbler for meat processing meat tumbler ham hobart meat tumbler industrial meat tumbler lance meat tumbler meat vacuum tumbler manufacturers meat tumbler for sale philippines tumblr meat smoker meat tumbler for sale small meat tumbler stx meat tumbler

Request for a quote

ET TAMBURU DONER TEKNIK

Turkey

Meat and sausage is prepared wtih mixer afterwards they are moved by a lift and then they are dropped into machine. Machine has cooling unit which provides 4 Degree celsius for staying fresh meat and warm is controlled by plc. The machine has vacuum unit it ensures penetrate sauage into meat. meat tumbler mixer meat tumblers for sale meat tumbler ebay meat tumbler for sale south africa meat tumbler reviews meat tumbler recipes tumblr meat processing vacuum meat tumbler canada commercial meat tumbler what does a meat tumbler do how to build a meat tumbler biro meat tumbler meat tumbler canada meat compost tumbler countertop meat tumbler cabela's meat tumbler challenger meat tumbler diy meat tumbler electric meat tumbler vacuum meat tumbler for sale vacuum tumbler for meat processing meat tumbler ham hobart meat tumbler industrial meat tumbler lance meat tumbler meat vacuum tumbler manufacturers meat tumbler for sale philippines

Request for a quote

SP GROUP

Spain

RST B ECO, our new thermoformable base web, is a recyclable polypropylene-based material that is suitable for heat treatments such as retort processing. Designed for vacuum packing, the material was created to meet the EU guidelines on the circular economy. This material is part of our ECO range, which comprises SP Group’s recyclable, monomaterial packaging solutions. The combination of the RST B ECO base web and PP HB ECOTOP flexible top film is a fully recyclable solution for vacuum packing, as more than 90% of it is polypropylene. The remaining materials do not interfere in the recycling process. Properties: High-barrier material, suitable for retort processing. High puncture and tear resistance. Applications: This material is ideal for food products that need to be sterilised and vacuum packed. It is perfect for pre-prepared, vacuum-packed fruit and vegetable products, such as corn, beetroot, etc.

Request for a quote

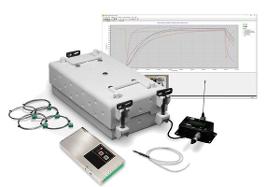

FLUKE PROCESS INSTRUMENTS GMBH

Germany

DATAPAQ Furnace Tracker systems offer accurate and reliable in-process temperature profiling and surveying solutions for a wide variety of demanding high temperature heat treatment processes in the glass and metalls industries and in aluminum manufacturing (Annealing * Brazing * Homogenizing * Decorating * Tempering * Forming * Frit Sealing * Normalizing * Billet Reheating * Slab Reheating * Pressure and Vacuum Processes). TB4000 Series Thermal Barriers: Rugged 304 stainless steel construction Microporous insulation provides the best thermal protection of any known material Various heights available to meet limited clearances TB4900 Series Thermal Barriers Exceptional durability and thermal resistance Outstanding resistance to oxidation and distortion One way lid and base alignment avoids thermocouple damage DATAPAQ temperature profiling systems comprise high-accuracy industrial-strength data loggers, thermocouples, thermal barriers, and analysis software.

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

DATAPAQ Reflow Tracker temperature profiling systems Program includes — range of high-accuracy, industrial-strength, compact Datapaq DP5 data loggers — range of low-height thermal barriers — DATAPAQ Insight Reflow Tracker analysis software — selection of fast-response, high-temperature thermocouples for measuring SMD and PCB temperatures and process stability Applications include — WAVE SOLDERING – accessory: DATAPAQ wave pallet with up to 9 contact sensors and 3 preheat sensors; software functions include contact times and parallelism — SELECTIVE SOLDERING – accessory: DATAPAQ PA2200 selective soldering sensor for process stability measurement — VACUUM SOLDERING – optional data transmission via radio enables real-time data analysis — VAPOR PHASE SOLDERING – program includes a special range of sealed and lighter-weight thermal barriers — REWORK STATIONS – the DATAPAQ DP5 data logger with its USB and Bluetooth connectivity is ideal for high-speed, real-time monitoring

Request for a quote

BORAN REKLAM LTD.

Turkey

Acrylic printings, which are in flat form, can be given special shapes by vacuum molds after printing. This process cannot be carried out because the elasticity of the inks used in the classical prints on the market is not high. However, thanks to the ink and printing system we use, it is possible to stretch 400 times. As Boran Reklam we do not vacuum but we produce acrylic printing suitable for vacuuming.

Request for a quote

FRIMO GROUP GMBH

Germany

For sophisticated decorative materials Press laminating is mainly used to process materials that are unsuitable for vacuum processes, such as textiles, materials with and without foam backings or non-stretchable cover materials like leather or Alcantara. Processing these materials requires high quality tooling and machinery to ensure the quality of the grain, the soft touch and the color remain intact. The decorative element and the substrate are usually laminated together by being pressed between two hard instruments. Precise decor positioning and tool arrangements ensure optimal laminating conditions. Other forms of laminating include leather laminating and membrane laminating, which combines press laminating, edge folding, trimming.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

DANA LUBRICANTS FACTORY LLC

United Arab Emirates

Base Oil SN 100 SN100 is a light base oil with its parameters being at the low end for lubricant stock. It is a Group I base oil made by further processing vacuum distillates of specific crude oil fractions. It is mostly used in lubricant and lubricant additives production. Applications : Base oil SN 100 works as a base stock for several industrial lubricants General purpose oils Mould oil Transmission fluids Gear oils Metal working fluids Additives Hydraulic oils Transformer oils

Request for a quote

GUANGZHOU WORLDE PACKAGING MACHINERY CO.,LTD

China

The small desktop vacuum skin packaging machine ,more suitable for small and medium-sized enterprises and processing plants .Vacuum packaging of fresh products.The small desktop vacuum skin packaging machine is a transformative way of packaging food, even sharp products can be wrapped like a second skin without changing the shape of the product. Vacuum skin packaging optimizes production, reduces packaging shrinkage in the sales process, and presents the best state of the product. Vacuum skin packaging is the latest packaging solution for cold bacteria products solution, ideal for packaging meat, poultry, seafood and cheeses that are sustainable, cost-effective, and guarantee the latest freshness of the product.Just press the start switch, then preheat-sealing-body-fitting-film-cutting-film-feeding and film-receiving-finished products come out, and it is automatically completed at one time.

BÜCHI AG

Switzerland

Glass pilot reactor and pilot plant Glass reactor: 15, 30, 60 liter Pressure: -1.0 (FV) to +0.5 bar Temperature: -60 °C (-90 °C) to +200 °C Material: Borosilicate glass 3.3, glass-lined steel, PTFE, PFA, tantalum A clean-room setup and other materials are available to meet your specific process requirements. Performance and reliability are key issues in the explosion proof design of Buchi glass reaction systems. The inert materials allow safe processing in an inert atmosphere of a wide range of solvents and acids in a completely sealed glass reaction system under full vacuum. Multiple chemical reaction steps are performed safely in the same setup. The system consists of: Reactor, solid jacketed full view glass reactor to easily improve and control chemical reactions by visual observation Distillation glass overhead built with buchiflex components (unique flexible ball - socket joints) for mulitple, reliable processes under full vacuum

Request for a quote

BÜCHI AG

Switzerland

Basic glass reactor systems for API synthesis, small scale production and pilot plant. Glass reactor: 15, 30, 60 liter Pressure: -1.0 (FV) to +0.5 bar Temperature: -60 °C (-90 °C) to +200 °C Material: Borosilicate glass 3.3, glass-lined steel, PTFE, PFA, Tantalum A clean-room setup and other materials are available to meet your specific process requirements. Performance and reliability are key issues in the explosion proof design of Buchi glass reaction systems. The inert materials allow safe processing in an inert atmosphere of a wide range of solvents and acids in a completely sealed glass reaction system under full vacuum. Multiple chemical reaction steps are performed safely in the same setup. The system consists of: Solid jacketed full view glass reactor to easily improve and control reactions by visual observation Distillation glass overhead built with buchiflex components (unique flexible ball - socket joints) for multiple, reliable processes under full vacuum

Request for a quote

AERO-LIFT VAKUUMTECHNIK GMBH

Germany

Not only uneven, structured surfaces but also undefi ned pick-up positions and varying dimensions can be easily be handled with the aid of the VUSS vacuum gripper. Be it in logistics, small trade or industry. AERO-LIFT® VUSS facilitates the use of vacuum lifting equipment now for your materials – regardless of whether a pallet of cans is not full or there is a pile of wooden boards laying loosely together or every workpiece has an individu-al, different size. process automation with vacuum gripper more efficiency and flexibility Function and features structure vacuum gripper The basic principle is really simple: The robot attaches a vacuum plate to the product to be transported instead of grabbing it. In such cases, it does not matter whether the products have holes, are slanted...

Request for a quote

DC DI CANDIA RUOTE

Italy

The POLY-D wheels are manufactured through a new vacuum - dryer - high pressure process, entirely developed by DC, which results in the higher quality wheel in its range of products. Lifetime of these wheels has been improved thanks to the complete absence of air bubbles inside the finished product, obtained through our new production process. The POLY-D wheels can be fitted into a specific series of brackets for which are specifically studied and produced to fulfill the extremely wide variability of conditions to which they are submitted, for both industrial and food industry. Brackets are fully certified and manufactured with food and sanitary grade Stainless Steel in AISI 304, and are available in both metric and inches standard sizes, and are also available in double-layer galvanized pressed steel. The POLY-D wheels can be used on trolleys for food industry, tannery industry, equipment and trolleys for meat and fish industry, slaughterhouses, ice cream machinery and flower trolleys

Request for a quote

DC DI CANDIA RUOTE

Italy

The D-FLEX wheels are manufactured through a new vacuum - dryer - high pressure process, entirely developed by DC, which results in the higher quality wheel in its range of products, and the only one to be covered by a lifetime warranty** against the de-bonding of the elastic Polyurethane tyre from the wheel centre, plus they grant a high cut and tear propagation resistance. Combines the load capacity and the resistance to wear and tear of the polyurethane with the ability to overcome obstacles and to reduce noise, vibrations and impacts of the elastic rubber. The Polyurethane tyre is mechanically bonded to the wheel core, and the coupling is further strengthened by a surface adhesion which is obtained without the use of any glue or chemical bonding. Recommended on trolleys for food industry and chemical industry, industrial trolleys, equipment and trolleys for meat and fish industry, slaughterhouses, pharmaceutical industry, floor-washing machines and scrubbers, and for traction.

Request for a quote

DC DI CANDIA RUOTE

Italy

The D-NAMIC wheels are manufactured through a new vacuum - dryer - high pressure process, entirely developed by DC, which results in the higher quality wheel in its range of products, and the only one to be covered by a lifetime warranty against the de-bonding of the Polyurethane tyre from the wheel centre. The Polyurethane tyre grant a high cut and tear propagation resistance, is mechanically bonded to the wheel core, and the coupling is further strengthened by a surface adhesion which is obtained without the use of any glue or chemical bonding. The D-NAMIC wheels can be fitted into a specific series of brackets for which are specifically studied and produced to fulfill the extremely wide variability of conditions to which they are submitted, for both industrial and food industry. D-NAMIC are recommended on trolleys for food industry and chemical industry, industrial trolleys, equipment and trolleys for meat and fish industry, slaughterhouses and textile industry.

Request for a quote

ALLVAC FOLIEN GMBH

Germany

Allflex B is a member of the product family of flexible PA/PE medium barrier multilayer bag films produced by means of coextrusion. The polyamide and polyethylene multilayer barrier film offers excellent stiffness values which have a positive effect on the output during bag production. The film is powdered lightly, making it thus easier for the consumer to open the bag. The allflex B 11-layer film is available in thicknesses from 65my to 85my and scores well in packaging processes under vacuum or MAP in both the food and non-food sectors. Due to its temperature tolerance it is also ideal for pasteurisation and microwave applications. Features of allflex B: Medium barrier against oxygen and water vapour High degree of transparency Excellent sealing properties Increased puncture resistance

Request for a quote

PROTEC POLYMER PROCESSING GMBH

Germany

ProTec designs and supplies innovative solid-state polymer post-condensation lines and complete PET bottle flake recycling lines. The batch tumble reactor which combines homogeneous mixing with short processing times is the keystone of the line. The IV value (intrinsic viscosity as a yardstick for molar mass) of polyesters (PET, PBT, PTT etc.) and of polyamides (PA6, PA66 etc.) can be purposefully increased by precise control of temperature, vacuum and processing time, with or without defined addition of auxiliaries.

Request for a quote

BOLZ PROCESS TECHNOLOGY GMBH

Germany

BSV Series DN 100 – 400 The Ball Segment Valve, BSV for short, is the result of a development of an innovative valve for pharmaceutical and fine chemical processes. For a wide range of solids applications, it is the preferred valve for process equipment like vacuum dryers, reactors or centrifuges as both as inlet and discharge valve. Even if products are not free flowing, have an abrasive effect or have moist and adhesive properties, the Ball Segment Valve is the right choice as a reliable, vacuum and pressure-tight process valve. The internal corner-free and edge-free housing does fullfill your cGMP requirements and leaves the ball segment sufficient space to move clear of the product flow path when opened. A reactor agitator or mixing tool can be designed to move within a few millimetres of the Ball Segment Valve virtually eliminating dead-space in the process area. Besides the standard flanges, the BSV can be equipped with tailored and non DIN flange connections to suit most...

Request for a quote

BOLZ PROCESS TECHNOLOGY GMBH

Germany

COMBER Pressofiltro® / Turbodry® Series PF/TD 5 - PF/TD 100 This Pilot Plant can either be used as Agitated Nutsche Filter/Filter Dryer or a Vacuum Dryer. Designed for processes in pilot plants, it is fully equipped for tests and trials and can as well be used for small scale production. Special properties for the customer’s benefit: Calculation, manufacture and design are in accord with Pressure Equipment Directive 97/23/EG or/and ASME U-stamp as well as with cGMP and FDA guidelines Approved for using in ATEX danger zone, group II 2G 2D (zones 1/ 21) Suitable as vacuum dryer, filter dryer or agitated nutsche filter Shaft seal through gland nut Device built on skid Control system protected against explosion (EEx-d) Options Multilayer PLC-system

Request for a quoteResults for

Vacuum processes - Import exportNumber of results

77 ProductsCountries

Category

- Surface treatment - machinery and equipment (12)

- Nuts (8)

- High-vacuum photo-cells (6)

- Food Processing (3)

- Wheels, castors and rollers (3)

- Chemical and pharmaceutical industry - machinery and equipment (2)

- Food packaging (2)

- Infrared tubes (2)

- Sensors (2)

- Temperature sensing devices (2)

- 3D printers (1)

- Armchairs (1)

- Cleaning machines, industrial (1)

- Conveyor belts (1)

- Cutters and splicers, film (1)

- Diesel engines (1)

- Electric and electronic components - machines for manufacturing (1)

- Extrusion, plastics - machinery (1)

- Filtration, chemical (1)

- Food Industry - Machines & Equipment (1)