- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- vacuum heating

Results for

Vacuum heating - Import export

XIAMEN NINESUN IMP. & EXP. CO., LTD

China

We use this vacuum degasser to clean all kinds of products before do the coating. This degas chamber is venting the gas,air and other impurities through putting in the heated N2. This vacuum degasser will greatly shorten the vacuum time, reduce the oxygen corrosion, protect the machine and prolong the life time of the equipment. It enhances the adhesion of the film in the products.

Request for a quote

XIAMEN NINESUN IMP. & EXP. CO., LTD

China

Introduction: 303 through hardened screw, has better corrosion resistance Tail annealing treatment, greatly improving the toughness of the screw CNC full grinding thread, tooth root top concentric and tooth bottom flatness high precision, can reduce the shear heat. Application: Low acid plastic + GF15 following, such as PMMA, PC and so on Temperature ≤400 ℃ Optical lenses, cosmetic packaging and so on Materials and Process: Material origin: Japan The main components: Cr, V, Mo and so on Heat treatment: vacuum quenching, hardness HRC48-52. (1020-1050 vacuum quenching, high temperature tempering 550-570 more than three times, the rear high temperature annealing softening treatment) Surface treatment: PVD coating (TiN, TiCN, TiAlTiN)

Request for a quote

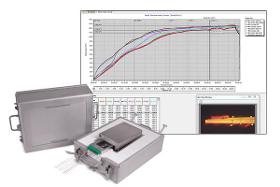

FLUKE PROCESS INSTRUMENTS GMBH

Germany

The Datapaq Vacuum Heat Treatment System from Fluke Process Instruments features the Datapaq TP6 data logger, choice of thermal barrier (TB45 or TB46), thermocouples and our intuitive Insight™ software to create a complete solution. The Furnace Tracker Systems that include the Datapaq TB45 series of thermal barriers can operate in temperatures up to 1050°C (1922°F) and the TB46 series can withstand temperatures of up to 1200°C (2192°F). Both are designed for use in vacuum and carburizing applications and can operate in pressures up to 20 Bar (290 PSi). Data Logger The Datapaq TP6 is the perfect solution for the most demanding high-temperature profiling applications with a 316-grade machined stainless-steel case and IP67 rating. Once combined with the Datapaq Insight™ or Datapaq Insight Furnace Surveying software you can display information from the data logger in real time via the optional Radio Frequency (RF) system or via standard USB/Bluetooth connections.

Request for a quote

INFICON GMBH

Germany

THE STANDARD IN GAS ANALYSIS Excellent Performance and Great Value for General Vacuum Applications As manufacturing technologies advance and quality standards change, the need to understand your process and maintain product quality is more important than ever. Transpector MPS can help you optimize your process by monitoring process conditions, detecting contaminants, and checking for leaks. Transpector MPS offers the robust performance of the Transpector brand of RGA at an excellent value for our customers. Transpector MPS is available in both 100 amu and 200 amu versions, which gives you the flexibility of performing a wide variety of functions including general leak detection, vacuum diagnostics, and hydrocarbon analysis. This versatility makes Transpector MPS the sensor of choice for vacuum furnace, heat treating, and vacuum coating applications. (1) at 10% of peak height (2) during an eight hour period, after a half hour warm up; in FC mode only (3) 256 millisecond dwell time

Request for a quote

PETER HUBER KÄLTEMASCHINENBAU SE

Germany

The compact Minichillers are an economic and environmentally friendly cooling solution for many laboratory applications. A calculation of water and waste water costs shows that a Minichiller can save up to 48,000 litres of water in a working week and due to its low procurement price, return on investment is achieved within a very short time. The units have small footprints, only requiring 225 x 360 mm on the laboratory bench and are therefore suitable for cooling reactor blocks, vacuum pumps, rotary evaporators or heat exchangers. Minichillers allow stable application conditions due to constant values for temperature, pressure and throughflow quantities. They are also perfect for continuous operation at ambient temperatures up to 40°C. Despite the economic purchase price the coolers are well equipped and have a large temperature indicator, fill level indicator, as well as status LEDs for the pump, cooling and heating. A 1 kW heater is optionally available with which the...

Request for a quote

PETER HUBER KÄLTEMASCHINENBAU SE

Germany

The compact Minichillers are an economic and environmentally friendly cooling solution for many laboratory applications. A calculation of water and waste water costs shows that a Minichiller can save up to 48,000 litres of water in a working week and due to its low procurement price, return on investment is achieved within a very short time. The units have small footprints, only requiring 225 x 360 mm on the laboratory bench and are therefore suitable for cooling reactor blocks, vacuum pumps, rotary evaporators or heat exchangers. Minichillers allow stable application conditions due to constant values for temperature, pressure and throughflow quantities. They are also perfect for continuous operation at ambient temperatures up to 40°C. Despite the economic purchase price the coolers are well equipped and have a large temperature indicator, fill level indicator, as well as status LEDs for the pump, cooling and heating. A 1 kW heater is optionally available with which the...

Request for a quote

PETER HUBER KÄLTEMASCHINENBAU SE

Germany

The compact Minichillers are an economic and environmentally friendly cooling solution for many laboratory applications. A calculation of water and waste water costs shows that a Minichiller can save up to 48,000 litres of water in a working week and due to its low procurement price, return on investment is achieved within a very short time. The units have small footprints, only requiring 225 x 360 mm on the laboratory bench and are therefore suitable for cooling reactor blocks, vacuum pumps, rotary evaporators or heat exchangers. Minichillers allow stable application conditions due to constant values for temperature, pressure and throughflow quantities. They are also perfect for continuous operation at ambient temperatures up to 40°C. Despite the economic purchase price the coolers are well equipped and have a large temperature indicator, fill level indicator, as well as status LEDs for the pump, cooling and heating. A 1 kW heater is optionally available with which the...

Request for a quote

PETER HUBER KÄLTEMASCHINENBAU SE

Germany

The compact Minichillers are an economic and environmentally friendly cooling solution for many laboratory applications. A calculation of water and waste water costs shows that a Minichiller can save up to 48,000 litres of water in a working week and due to its low procurement price, return on investment is achieved within a very short time. The units have small footprints, only requiring 225 x 360 mm on the laboratory bench and are therefore suitable for cooling reactor blocks, vacuum pumps, rotary evaporators or heat exchangers. Minichillers allow stable application conditions due to constant values for temperature, pressure and throughflow quantities. They are also perfect for continuous operation at ambient temperatures up to 40°C. Despite the economic purchase price the coolers are well equipped and have a large temperature indicator, fill level indicator, as well as status LEDs for the pump, cooling and heating. A 1 kW heater is optionally available with which the...

Request for a quote

PETER HUBER KÄLTEMASCHINENBAU SE

Germany

The compact Minichillers are an economic and environmentally friendly cooling solution for many laboratory applications. A calculation of water and waste water costs shows that a Minichiller can save up to 48,000 litres of water in a working week and due to its low procurement price, return on investment is achieved within a very short time. The units have small footprints and are therefore suitable for cooling reactor blocks, vacuum pumps, rotary evaporators or heat exchangers. Minichillers allow stable application conditions due to constant values for temperature, pressure and throughflow quantities. They are also perfect for continuous operation at ambient temperatures up to 40°C. Despite the economic purchase price the coolers are well equipped and have a large temperature indicator, fill level indicator, as well as status LEDs for the pump, cooling and heating. A heater is optionally available with which the temperature range can be extended to +100°C. Minichillers are...

Request for a quote

PETER HUBER KÄLTEMASCHINENBAU SE

Germany

The compact Minichillers are an economic and environmentally friendly cooling solution for many laboratory applications. A calculation of water and waste water costs shows that a Minichiller can save up to 48,000 litres of water in a working week and due to its low procurement price, return on investment is achieved within a very short time. The units have small footprints and are therefore suitable for cooling reactor blocks, vacuum pumps, rotary evaporators or heat exchangers. Minichillers allow stable application conditions due to constant values for temperature, pressure and throughflow quantities. They are also perfect for continuous operation at ambient temperatures up to 40°C. Despite the economic purchase price the coolers are well equipped and have a large temperature indicator, fill level indicator, as well as status LEDs for the pump, cooling and heating. A heater is optionally available with which the temperature range can be extended to +100°C. Minichillers are...

Request for a quote

PETER HUBER KÄLTEMASCHINENBAU SE

Germany

The compact Minichillers are an economic and environmentally friendly cooling solution for many laboratory applications. A calculation of water and waste water costs shows that a Minichiller can save up to 48,000 litres of water in a working week and due to its low procurement price, return on investment is achieved within a very short time. The units have small footprints and are therefore suitable for cooling reactor blocks, vacuum pumps, rotary evaporators or heat exchangers. Minichillers allow stable application conditions due to constant values for temperature, pressure and throughflow quantities. They are also perfect for continuous operation at ambient temperatures up to 40°C. Despite the economic purchase price the coolers are well equipped and have a large temperature indicator, fill level indicator, as well as status LEDs for the pump, cooling and heating. A heater is optionally available with which the temperature range can be extended to +100°C. Minichillers are...

Request for a quote

PETER HUBER KÄLTEMASCHINENBAU SE

Germany

The compact Minichillers are an economic and environmentally friendly cooling solution for many laboratory applications. A calculation of water and waste water costs shows that a Minichiller can save up to 48,000 litres of water in a working week and due to its low procurement price, return on investment is achieved within a very short time. The units have small footprints and are therefore suitable for cooling reactor blocks, vacuum pumps, rotary evaporators or heat exchangers. Minichillers allow stable application conditions due to constant values for temperature, pressure and throughflow quantities. They are also perfect for continuous operation at ambient temperatures up to 40°C. Despite the economic purchase price the coolers are well equipped and have a large temperature indicator, fill level indicator, as well as status LEDs for the pump, cooling and heating. A heater is optionally available with which the temperature range can be extended to +100°C. Minichillers are...

Request for a quote

HAAG + ZEISSLER MASCHINENELEMENTE GMBH

Germany

universal usecooling, heating, clamping with bellows sealing Modular unit designcustomer taylered configuration, fast and economic cartridge fast change CDcartridgedesign sealingmaterial ceramics/graphite. For coking heat transfer oil with temperature higher than 230 °CVersion HT with diamondhard sealface and hightemperature graphitesealring solid grease ballbearingsmaintenance free no elastomerstherefore no temperature and chemical resistance problems no loose parts, f.e. springs robust and less influence of dirty media self supportingno additional support necessary available in stainless steel PRESSURE MAXIMUM 6,0 bar air heat transfer oil TEMPERATURE MAXIMUM 300 °C air heat transfer oil vacuum SPEED MAXIMUM 250 1/min DN 100 (4") 300 1/min DN 65 (2 1/2") DN 80 (3") 400 1/min DN 50 (2") SIZEDN 50 (2") DN 65 (2 1/2") DN 80 (3") DN 100 (4")

Request for a quote

FERPLAST SNC

Italy

WORKBENCHES BUILT IN STURDY TUBULAR AND MADE TO MEASURE The counters are made with a sturdy 60x60 mm painted tubular structure and the tops are also suitable for contact with food, as they are made of food grade nylon or stainless steel. They are ideal for wrapping and packaging products and supporting benchtop vacuum machines, heat sealers and welding machines. They can also be inserted in assembly and packaging lines, equipping them with reel holder systems or bench cutters. We can make benches with customized lengths from approximately 500 to 2500 mm and with any required width. The counters can be equipped with drawers (single or double) with sliding guides, rear or side panels and under-top. The tables are very sturdy, built in painted steel and can be ordered in the "simple" version with a NYLON top. The "simple" version is equipped with 4 adjustable rubber supports. Upon request, when ordering, the kit consisting of 4 wheels with parking brake can be mounted.

Request for a quote

HUNGARIAN FLAVOURS LTD.

Hungary

Vacuum packed heat-treated ground walnut ( walnut meal) Packaging: 200g - 5 Kg Moisture: max 5 % Fineness: can be negotiated Colour: light

Request for a quote

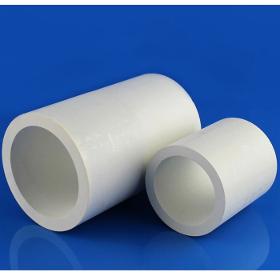

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Boron nitride can be long-term used at 1800 degrees under vacuum atmosphere. With gas protection, Boron Nitride can be used at 2100°. Boron Nitride is with high thermal shock resistance, no cracks under extreme cold & high temperature. If you take out Boron Nitride from 1000 degree furnace and colding it within short minutes. It still won't break even repeat this test with 100 times. > Matching materials: BN-99, BN-AL > Advantages: high temperature resistance (2000℃), thermal shock resistance, high electrical breakdown strength (3 -4 times that of alumina), carbon atmosphere corrosion resistance is much stronger than alumina > Used for polysilicon ingot furnace, graphitization heat treatment furnace, vacuum sintering furnace, atmosphere furnace ect. Grades 5 grades of boron nitrides are involved in Boron Nitride product series. * BN99 ● CABN ● ALBN ● ZRBN ● ZABN ● SB

Request for a quote

BALLERSTAEDT & CO. OHG

Germany

SEAMIAUTOMATIC SEALING DEVICE suitable for the sealing of all sorts of plastic and glass containers. 1. foil application device PolySeal Vario DIS (left hand side) electro-pneumatic stepless pressure regulation stepless manual height adjustment with height scale foil dispensing with 2 spot pre-sealing removable pre-sealing plates heat protection shield vacuum suction nozzle roller guide with running slide foil magazine for stackable pre-cut sealing lids VARIOTRONIC, control unit for the regulation of temperature, sealing time and pressure 2. sealing device PolySeal Vario PN (right hand side) electro-pneumatic stepless pressure regulation stepless manual height adjustment with height scale sealing head heating block, swingable, anodised aluminium hollowed out sealing die heat protection shield container holder VARIOTRONIC, control unit for the regulation of temperature, sealing time and pressure

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

FRIMO GROUP GMBH

Germany

Ideal for high quantities In vacuum laminating, plastic films such as TPO, TEPEO2 ® and PVC are heated and vacuumed to plastic substrate components, resulting in lamination. The adhesive applied to the substrate or decor material is activated, causing the two parts to bond. Vacuum laminating's special feature is that is can be combined with IMG (In-Mold Graining) in a single process. FRIMO offers this innovative and attractive technology with extensive market references.

Request for a quote

VOGAMAKINA INDUSTRIAL PLANTS LTD. CO.

Turkey

The oven is specially designed for the transfer process that works with the sublimation principle to give wood, marble or special effects to the outer surface of aluminum profiles and sheets. The pattern on a polyester film is transferred to the outer surface of the previously base powder coated aluminum profiles or sheets using vacuum application and heat. Wood effect transfer system consists of a trolley with special vacuum heads, a vacuum pump system, sublimation oven with circulation system and fully PLC control system.

Request for a quote

GUANGZHOU WORLDE PACKAGING MACHINERY CO.,LTD

China

The automatic continuous stretch vacuum packaging machine is mainly formed by heating and stretching through the lower film, then filling the packaging into the formed lower film cavity, and then entering the heat sealing vacuum chamber to vacuum or inflate the packaging, and put the upper. The film is heat-sealed with the lower film to form a packaging bag, and the packaging is divided by cross-cutting and longitudinal cutting. The finished product output of packaging can be completed automatically at one time, the operation is simple, the labor force is greatly reduced, and the difficulty of recruiting is solved, thereby improving the product quality, beautifying the production environment, improving production efficiency, saving time, labor, and efficiency, etc. Real automation equipment. Application: All kinds of meat,fresh meat, aged meat, sausages, Seafood fish,Dried fruits,Vegetables ,Ready to eat meals,Cheese, Pasta, noodles totally dried cereals, corn kernels, peanuts, etc.

GUANGZHOU WORLDE PACKAGING MACHINERY CO.,LTD

China

Rollstock vacuum skin packing machine suitable for medium and large batch packaging enterprises. It is mainly formed by heating and stretching through the lower film, then filling the packaging into the formed tray, entering the heat sealing vacuum chamber to vacuum the packaging. skin-to-body vacuum packaging adheres to the surface of the product like a second skin, which can firmly lock in moisture. Vacuum body packaging, with refrigeration can greatly extend the shelf life. Improve the appearance value, strong three-dimensional sense, transparent and beautiful, easy to touch and inspect, and neat and beautiful.The product is fastened to the tray, which can be shockproof, anti-friction, and anti-scratch; and vacuum-sealed, which can prevent moisture, oxidation, etc., to protect the quality of the product. From automatic forming tray-manual feeding-automatic packaging-automatic cutting-automatic output, etc., it can be completed automatically at one time, greatly reducing labor.

UNITED PROCESS CONTROLS GMBH

Germany

Our modular control packages are customized to significantly improve your vacuum heat treat operations, meet industry standards requirements and ultimately provide you with precise and reliable process control. We offer compact, fully automatic modules for new installations or retrofits. Each solution consists of a cost-effective module or combination of modules delivered with state-of-the-art equipment and backed by our extensive technological expertise. Vacuum Control Solution is supplied with a PROTHERM programmable controller and optional multiple load thermocouple inputs for soak guarantees. Interfaces to popular vacuum gauges. FEATURES • Full compliance with AMS 2750, CQI-9, NFPA 86-C, NADCAP* • Expanded recipe control including automatic leak test cycles • Guaranteed soaks based on multiple work thermocouples • Recipe control of partial pressure setpoints, guaranteed soak, ramp rates, events and quench gas selection • Built-in uniformity survey capability • Temperature...

Request for a quote

BOLZ PROCESS TECHNOLOGY GMBH

Germany

Series CCD (100 - 20,000 liters) The Cylindro Conical Dryer CCD with a central shaft agitator was developed to be used both as a dryer (e.g. for filter cake) and also an evaporator when products have to pass a critical phase change from fully liquid to final bulk solid. The robust mixing element is showing its effective performance also during liquid and high viscous pasty phase to finally achieve the desired solid phase. As a dryer it is designed with a vacuum-/pressure rated vessel, heating jacket and integrated dust filter. Like for the CCM (Cylindro Conical Mixer) also the CCD offers a big advantage with a compact and space saving design. Special properties for the customer’s benefit: Short drying times because all product of the batch is permanently in motion thanks to a heated helix agitator (optional) Uniform heat distribution during the process without cold spots Variable speed of the helix agitator for optimum product quality Useful working volume from 15% to 80% of the...

Request for a quote

PVA INDUSTRIAL VACUUM SYSTEMS GMBH

Germany

Heat Treatment furnaces MOV are ideal for the treatment of sophisticated materials if high temperatures and an absolutely clean hydro-carbon free atmosphere are required. Due to the ultrahigh vacuum atmosphere as well as the extreme temperature homogeneity and the fully automatic process the furnaces are especially suitable for the economic application in industrial and medical productions, i.e. for brazing of vacuum interruptors, parts of x ray tubes, heat exchangers, parts used in the medical and aerospace industry. Applications: MOV furnaces are universally applicable if heat treatment with particularly high requirements in respect of cleanliness for exacting materials is involved, for example: • Degassing of electric or radiation tube components • Bright- and stress-free annealing of high-temperature alloys • Sintering of high-melting and heavy metals such as tungsten • Production of high-quality fluxless braze joinings of steels, steel-ceramics and many other materials.

Request for a quote

PVA INDUSTRIAL VACUUM SYSTEMS GMBH

Germany

OV heat treatment furnaces are high performance most efficient furnaces with a wide working-temperature and application range. Due to the compatibility with all kind of process gases and the fully automatic process runs they are especially suitable for the economic application in industrial productions for example to produce hard metals or the cleaning and purification of graphite. Applications: • operating temperatures up to 1.100 °C: heat treatment, brazing, reduction, degassing and debinding • operating temperatures up to 1.350 °C: heat treatment, brazing, degassing, debinding and sintering • operating temperatures up to 1.600 °C: debinding and sintering of hard metals • operating temperatures up to 1.800 °C: sintering of non-oxydic ceramics • operating temperatures up to 2.000°C: CVD- and pyrolytic processes, degassing, cleaning, sintering • operating temperatures up to 2.400 °C: CVD-processes, degassing, cleaning • operating temperatures above 2.

Request for a quote

PVA INDUSTRIAL VACUUM SYSTEMS GMBH

Germany

Inductively heated vacuum heat treatment furnaces with high operating temperatures specially for the manufacture of hard materials. Standardized components for a broad application spectrum and useful space volumes from 34 to 338 litres. Applications: IOV furnaces are used for all high temperature processes and serve for sintering and heat treatment processes such as degassification, graphitizing, destillation, impregnating, infiltration, reducing and carburization. Benefits for users: An extremely robust type of system, especially appropriate for processes where dust incidence or high temperatures are involved.

Request for a quote

PVA INDUSTRIAL VACUUM SYSTEMS GMBH

Germany

High-vacuum heat-treatment furnaces with integrated pressing unit and power-regulated resistance heater elements (Hot Press). Used for diffusion bonding and forming processes under high vacuum conditions as well universal use for thermal treatments and processes where particularly demanding requirements and sophisticated materials are involved.

Request for a quote

EKOTERRA FOOD SRL

Italy

Ekoterra offers a variety of organic and conventional fruit and vegetable powders that can be used in a variety of ways, including confectionery, sauces, protein mixes, fillings, and more. These powders are fine, normally highly soluble, and have a long shelf life, making them ideal for food processing. These powders can be: Dried with a belt, roller, or drum (fruit and vegetables are heated then milled) Spray-dried (juice is sprayed through a nozzle at a high temperature to produce a dried product). Dryed in a vacuum (heated in vacuum, meaning lower temperature required for water evaporation) Dehydrated in the freezer (frozen in a vacuum chamber meaning water sublimates out) Banana Powder Beet Root Powder WatermelonPowder Peach Powder Kiwi Powder Lemon Powder Melon Powder MAngo Powder Strawberry Powder Tomato Powder Red Pepper Powder

Request for a quote

LIQUOSYSTEMS GMBH

Germany

Plate heat exchangers are a part of the wort cooling in the beer production process. Made of stainless steel. The heat exchangers are vacuum-hard wired. They must be made of stainless steel plates and copper solder, which are looking at stainless steel.

Request for a quoteResults for

Vacuum heating - Import exportNumber of results

32 ProductsCompany type

Category

- Heat treatment furnaces (4)

- Coating machinery (2)

- Packing and packaging - machinery and equipment (2)

- Ceramics (1)

- Electric motors and parts (1)

- Heat exchangers (1)

- Heat treatment of steels and metals (1)

- Infrared tubes (1)

- Nuts (1)

- Package stamping machinery (1)

- Screws (1)

- Temperature sensing devices (1)

- Vegetables, freeze-dried (1)

- Workbenches (1)