- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- used injection moulding machines

Results for

Used injection moulding machines - Import export

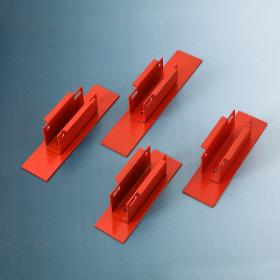

DONGGUAN XINHONGYUAN METAL PRODUCTS LIMITED

China

This metal bracket is called bucket, carrier or clamp, which is used on injection molding machine, to fix the digital display on the machinery body, many brackets or clamps are used to hold electronics or goods on the body or on the wall, the metal brackets / clamps can be "L"shape,"M"shape, "U"shape,etc, which are mainly formed by metal stamping, the material can be flexible like iron, steel, stainless steel, aluminum, spring steel.

Request for a quote

AYBERKSAN PLASTIK KALIP SANAYI

Turkey

Injection mold production is a complex process that cannot be underestimated. The resulting product is the main element to be used in injection molding machines. Therefore, at every stage of the process, there are improvements that need to be made in line with the research and the data obtained from these researches. The R&D process, which started with the examination of the samples we received, continues at the design and injection stages. As AYBERKSAN, our aim is not to present a large number of products with the existing data, but rather to increase the data we have and to present better quality, problem-free and economical solutions. The process we call development cannot happen without research. With this awareness, we, as AYBERKSAN Kalıp Sanayi, continue our research to take the experience we have gained so far to the next level, to add a new one and to develop it.

Request for a quote

NINGBO FRIMA INDUSTRY CO. LTD.

China

screw and barrel for rubber extruder Material: HVOF Spray Coating Screw, PTA Spray Welding Screw, Nitriding Screw Application: For use in the Injection Moulding Machine , Extrusion Moulding Machine, Bakelite Moulding Machine, and Rubber Moulding Machine. Processing Dimension:Min External Diameter Ø 12mm, Max External Diameter Ø 250mm,Effective length Ø 8000mm . Machining SCREW Heat-treatment, Nitriding treatment, Electroplated hard-chrome finish, High-frequency quenching, Spray coating bimetallic-alloy, Vacuum quenching. Customer’s specification and drawing are accepted in the manufacturing various materials of pillars, columns, tie bars, guide rods which applicable to various plastic, rubber injection molding machine, hydraulic machine, diverse machine tool etc. (Special dimension and spec. are also acceptable. )

Request for a quote

FRIEDENSTAB KUNSTSTOFFTECHNIK GMBH

Germany

With a modern machine park, we are able to produce injection molded parts up to approx. 400 grams. The materials used for this are e.g. PS, ABS, PP and PE, but also technical plastics. With a modern machine park, we are able to produce injection molded parts up to approx. 400 grams. The materials used for this are e.g. PS, ABS, PP and PE, but also technical plastics such as PA6, POM or IXEF are often used. Brief overview ARBURG injection molding machines Component weight: approx. 2 - 400 grams Closing forces: 50 - 220 tons Hybrid components (insert / outsert technology) Removal robots / vacuum gripping systems Automation around the injection molding process Central material handling system Material preparation Material drying

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Used injection moulding machines - Import exportNumber of results

4 ProductsCountries

Company type