- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- steam ejector

Results for

Steam ejector - Import export

JET FLOW TECHNOLOGIES UK LIMITED

United Kingdom

A Variable Flow Erectors are pneumatically / Electrically operated single nozzle ejectors, used to handle the variable suction ad discharge conditions wherein pneumatically / electrically operated needle goes in and out for precise controlling the flow rate based on pressure requirement. It is very useful when a low pressure steam is compressed to a higher pressure level.

Request for a quote

JET FLOW TECHNOLOGIES UK LIMITED

United Kingdom

Vacuum is necessary during various steps of edible / vegetable oil and food processing. These steps essentially include hydrogenation, fractionation, bleaching, deodorization and deacidification. Out of all vacuum equipments, Ejector Vacuum System has established the superiority and versatility of their use as compared to mechanical vacuum pumps. The most outstanding advantage of the Steam Jet Ejector is total absence of moving parts which eliminate mechanical breakdown, and assures constant and dependable operation with freedom from repairs. No adjustment or lubrication is required nor are any specially trained operator necessary as their operation is very simple. Over and above, Steam Jet Ejector Vacuum System convey at very high velocity which are many times the speed of sound, they are capable f handling large volume under vacuum thus making them eminently suitable for deodorization application wherein high quality of open / sparging steam has to be handled.

Request for a quote

JET FLOW TECHNOLOGIES UK LIMITED

United Kingdom

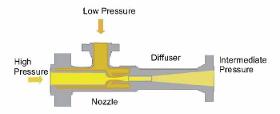

Large industrial plants often vent significant quantities of low pressure steam to the atmosphere, wasting energy, water, and watertreatment chemicals. Recovery of the latent heat content of lowpressure steam reduces the boiler load, resulting in energy and fuel cost savings. Lowpressure steam's potential uses include driving evaporation and distillation processes, producing hot water, space heating, producing a vacuum, or chilling water. If the steam pressure is too low for the intended application, a steam jet thermocompressor can boost the pressure and temperature to the required level. Operating Principles - Thermocompressors and ejectors operate on the same thermodynamic and physical principle energy contained in high pressure steam can be transferred to a lower pressure vapor or gas to produce a mixed discharge stream of intermediate pressure.

Request for a quote

JET FLOW TECHNOLOGIES UK LIMITED

United Kingdom

The efficiency of a Steam turbine is mainly determined by the pressure of the steam at its outlet. The Turbine Surface Condenser is therefore maintained under vacuum. To enable this, the Steam Jet Ejector Vacuum System must be capable of removing all non condensable and associated water vapour from the Surface Condenser to produce the minimum steam condensing pressure consistent with physical dimensions and heat transfer and to provide for deaeration of the condensate. The sources of non condensables include air leakage through all system components operating below atmospheric pressure, gases released from feedwater drains and vents admitted to the condenser, gases released for makeup admitted to the condenser, condensate surge tank when utilized in a closed cycle and disassociation of feedwater into oxygen, hydrogen and non condensables.

Request for a quote

JET FLOW TECHNOLOGIES UK LIMITED

United Kingdom

Based on the process requirement, a Multi Nozzle Ejectors can be designed five or seven nozzles type. Generally, one nozzle in the centre and remaining four or six nozzles are evenly circled around it. Multi Nozzle Ejectors can reduce the steam consumption by 15% to 20% as compared to Single Nozzle Ejectors when designed for the same conditions and it is more efficient to single nozzle ejectors. At times it is also considerably shorter in length when compared with same rated single nozzle ejectors.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

JET FLOW TECHNOLOGIES UK LIMITED

United Kingdom

Three Stage Ejector is similar in construction as of Single Stage Ejector, but having intermediate condensers. Three Stage Ejector comprises of Booster Ejector, Booster condenser and a Two Stage Ejector. And Two Stage Ejector consists of a high vacuum ejector, a inter condenser and a low vacuum ejector. This system will give higher vacuum and can handles larger quantity of condensable vapors. Gas or Gas vapor mixture is discharged from the first stage into the condenser where the operating steam is condensed and gases are cooled. The cooled gases are then entrained by the second stage and discharged into the second inter condenser. Here, the steam used in the second stage is condensed. The gases are finally entrained by the third stage and discharged to atmosphere.

Request for a quote

JET FLOW TECHNOLOGIES UK LIMITED

United Kingdom

Five Stage and Six stage Steam Jet Ejectors with Condenser Five stage and six stage ejectors are designed for absolute pressure in Micron Range. The arrangement of these ejectors is similar to the four stage ejector with additional one or tow non condensing stages. Special Precautions while measuring Low Absolute Pressures : Do not use spring type vacuum Gauges Ensure that the guage tubes are clean and free form contamination Ensure that the guage liquid is clean and free from contamination

Request for a quote

JET FLOW TECHNOLOGIES UK LIMITED

United Kingdom

SingleStage Steam Jet Ejectors are based on the ejectorventuri principle. In operation, steam issuing through an expanding nozzle has its pressure energy converted to velocity energy. A vacuum is created and the high velocity of steam entrains air or gas and the mixture of gas and steam enters the converging end of the venturi, passes through the diffuser where its velocity energy is converted into pressure sufficient to discharge against a predetermined back pressure. Single stage steam jet ejectors are used to create vacuum covering 40 mm Hg. Absolute. Two Stage Ejector with Condenser The system is the assembly of two units whose construction is similar to single stage with inter condenser (direct contact type or surface type). Steam of the first stage is expanded through nozzle entrains the air or other gases and discharges them to diffusers at a higher pressure in the condenser.

Request for a quote

JET FLOW TECHNOLOGIES UK LIMITED

United Kingdom

Water jet ejector uses water as motive force. Liquid Jet Eductors use the kinetic energy of a motive liquid to entrain another liquid,completely mix the two, and then discharge the mixture against a counter pressure and are used in large numbers throughout industry for pumping and mixing operations. Water Jet Eductors consist of three basic components, namely a converging nozzle, a diffuser (or venturi), and a body to hold these parts in their relative positions and to provide a suction (or mixing) chamber. In addition, they can be equipped with accessories such as regulating spindles. Water Jet Eductors can also be staged with higher vacuum steam ejectors. In this case, the eductor serves both as the final pumping stage as well as a fairly good direct contact condenser, condensing the motive steam from the high vacuum steam ejectors.

Request for a quote

JET FLOW TECHNOLOGIES UK LIMITED

United Kingdom

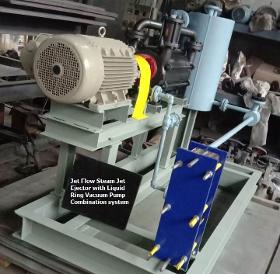

Jet Flow Steam Jet Ejector and Liquid Ring Pump Combination type Hybrid Ejectors Systems are getting popular in major Chemical, Soap, Food, Edible oil sectors. A typical combination of steam jet ejector system followed by inter-condenser and liquid ring vacuum pump. This type of combination system can achieve vacuum as high as 0.05 Torr. It can be configured as single or multistage ejectors, single or two stage liquid ring vacuum pumps and inter-condenser. It is designed to operate at the same capacities and suction pressures as conventional steam jet ejector systems. Jet Flow Hybrid Ejectors provide a solution for high vacuum operations. They are versatile in handling both wet and dry loads, can be supplied with low level skid mounted packages with instrumentation and with closed loop seal water recycle system for vacuum pumps for the total reduction of effluent. Jet Flow combination type vacuum systems major applications in distillation, evacuation, drying, evaporation, cooling etc.

Request for a quote

JET FLOW TECHNOLOGIES UK LIMITED

United Kingdom

When it comes to the performance of a turbine surface condenser in the operational field of a steam turbine cycle, you need utmost reliability and efficiency. Here’s where Jet Flow’s know how is invaluable. We createcustomise package solutions for each particular customer’s needs. Our General Scope of Supply Condenser Circular Condenser having own Flow, Axial flow or side inlet steam entry. Turbine to Condenser steam duct, including necessary expansion joints. Steam Jet Ejector Vacuum System. Flash tank, drain header and Instrument stand pipe. Dump Tube. Condensate Pump system Pumps are in vertical or horizontal arrangement; either API 610, ISO 5199 or standard manufacturer pump design. Control system Including level control valves pressure and temperature indicators, transmitters and controllers. Interconnecting piping with filter, fittings and valves.

Request for a quoteResults for

Steam ejector - Import exportNumber of results

12 ProductsCountries

Company type