- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- plating

Results for

Plating - Import export

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Taper Ground for Minimal Runout Custom Adaptors are Available Available to suit range of spindle noses To Suit A2 Spindle NosesStandard spindle adaptors to suit power chucks with a 380mm recess. Range of adaptors to suit different spindles heads. High accuracy taper and outer diameter.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Taper Ground for Minimal Runout Custom Adaptors are Available Available to suit range of spindle noses To Suit A2 Spindle NosesStandard spindle adaptors to suit power chucks with a 380mm recess. Range of adaptors to suit different spindles heads. High accuracy taper and outer diameter.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

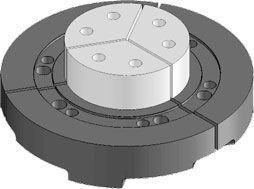

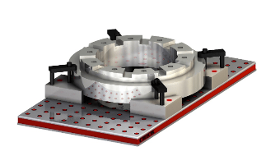

Universal quick change system for any chuck Repeatability < 0.001" TIR Reduce setup and changeover times by up to 80% Eliminate out of round conditions and concentricity problems DESCRIPTION When it comes to turning/holding smaller diameter parts Abbott’s precision master plate and segment system is an ideal choice for high changeover and short running jobs. Due to the system’s high repeatability, it is an excellent alternative to more expensive quick change chucks. The system consists of an aluminum master plate, similar to a thin Pie Jaw®, which is bored and bushed to accommodate Abbott’s standard, off-the-shelf pinned segments. Plates are available in 8, 10 and 12 inch diameters and can be mounted on 4-12 inch diameter chucks. The master plate can be custom machined to fit any model chuck, making it a permanent universal fixture on any machine.When using this system, the transition from one job to the next simply requires bolting on a new size or configuration of segments

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Universal quick change system for any chuck Repeatability < 0.001" TIR Reduce setup and changeover times by up to 80% Eliminate out of round conditions and concentricity problems DESCRIPTION When it comes to turning/holding smaller diameter parts Abbott’s precision master plate and segment system is an ideal choice for high changeover and short running jobs. Due to the system’s high repeatability, it is an excellent alternative to more expensive quick change chucks. The system consists of an aluminum master plate, similar to a thin Pie Jaw®, which is bored and bushed to accommodate Abbott’s standard, off-the-shelf pinned segments. Plates are available in 8, 10 and 12 inch diameters and can be mounted on 4-12 inch diameter chucks. The master plate can be custom machined to fit any model chuck, making it a permanent universal fixture on any machine.When using this system, the transition from one job to the next simply requires bolting on a new size

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Reduce setup and changeover times by up to 80% Eliminate out of round conditions and concentricity problems Effectively double the holding capacity of any chuck without eliminating the ability to hold small parts Light-weight 6061 T-6 or 319 for weight saving DESCRIPTION Abbott‘s master plate and segment system is a great choice for turning larger diameter work pieces. The system consists of an aluminum master plate, similar to a thin Pie Jaw®, which is pre-drilled and keyed to accommodate Abbott’s standard, off-the-shelf segment rings. Plates are available in various diameters from 15 to 60 inches and can be mounted on 8-60 inch diameter chucks, effectively increasing the holding capability of smaller chucks. The master plate can be custom machined to fit any model chuck, making it a permanent universal fixture on any machine.When using this system, the transition from one job to the next simply requires bolting on a new size or configuration of segments before continuing

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

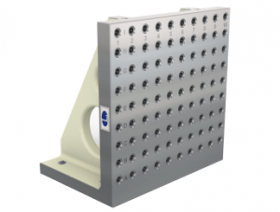

Allignment Busing and Thread Hole for Quick Accurate Set-ups Ground Flat and Parallel Cast iron gridded angle plate .Grid pattern with allignment bushes and threaded inserts for ease of set-up. Ground flat parallel and perpendicular for accuracy. To suit verticle or horizontal machining centre applications.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Machinable to accept required hole pattern Ground Flat Five High Accuracy Location Holes Cast Iron Sub Plate to suit rotary table or indexer. Plain to allow for machining of hole patterns and features required for special jigs or fixtures. Ground flat with Locating Holes for precise loading and quick set-up.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Centre Cover protects from Swarf Entering Inside the Chuck Replacement dust cover to suit a B200 power chuck. The cover plate is used to protect the internal parts of the chuck from swarf ingress.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Uses the HSK-A type, time-proven tool holder shank to connect the head and the work-piece holder. Off-line setup in advance allows quick work-piece changing, minimizing machine downtime. Accepts a variety of workholders Excellent workpiece accessibility In the case where you can’t mount the head directly to your machine table, please use this mounting plate. We can supply a blank that is customisable and also manufacture a special mounting plate just for you. For more information, please feel free to contact us.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

T-Slots to allow for Flexible use for Fixturing Products Ground Flat Five High Accuracy Location Holes Cast Iron Sub Plate to suit rotary table or indexer. T-Slot pattern to allow for easy flexible set-up of fixturing components. Ground flat with Locating Holes for precise loading and quick location.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Sturdy Cast Iron Design Ground Flat and Parallel Modular quick change subplate to suit the BP13 modular cube. This plate is gridded to accept standard fixturing parts./

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Allignment Busing and Thread Hole for Quick Accurate Set-ups Ground Flat Five High Accuracy Location Holes Cast Iron Sub Plate to suit rotary table or indexer. Grid pattern with allignment bushes and threaded inserts for ease of set-up. Ground flat with Locating Holes for precise loading and quick location.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

A Chick Workholding Foundation Plate is tailored to fit the machine’s specifications. A standard grid pattern to simplify designing, cataloguing and utilisation of fixtures, providing consistency and repeatability to set-ups. Length and width tailored to the machine’s work envelope. Precision ground cast iron to 35mm thick. 50mm spaced holes, drilled and tapped, for use as both location and hold down. Sealed with chip plugs. An alpha-numeric labelling system. Minimises set up time from workholding system to system. Machine interface mounting holes, customised for each machining centre.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Machinable to accept required hole pattern Ground Flat and Parallel Locating Holes for easy Set-Up Cast iron plain fixture plate with mounting holes. Plain to allow for the machining of hole patterns and features required for specific fixtures. Ground flat parallel and perpendicular for accuracy. Two dowel holes allow for precise loading and setting up of the fixture plate.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Machinable to accept required hole pattern Ground Flat and Parallel Locating Holes for easy Set-Up Cast iron plain fixture plate with mounting holes. Plain to allow for the machining of hole patterns and features required for specific fixtures. Ground flat parallel and perpendicular for accuracy. Two dowel holes allow for precise loading and setting up of the fixture plate.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Allignment Busing and Thread Hole for Quick Accurate Set-ups Ground Flat and Parallel Locating Holes for easy Location Cast iron fixture plate with mounting holes. Grid pattern with allignment bushes and threaded inserts for ease of set-up. Ground flat parallel and perpendicular for accuracy. Two dowel holes allow for precise loading and setting up of the fixture plate.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Reduce setup and changeover times by up to 80% Eliminate out of round conditions and concentricity problems Effectively double the holding capacity of any chuck without eliminating the ability to hold small parts Light-weight 713 Tenzaloy for weight saving DESCRIPTION Abbott‘s master plate and segment system is a great choice for turning larger diameter work pieces. The system consists of an aluminum master plate, similar to a thin Pie Jaw®, which is pre-drilled and keyed to accommodate Abbott’s standard, off-the-shelf segment rings. Plates are available in various diameters from 15 to 60 inches and can be mounted on 8-60 inch diameter chucks, effectively increasing the holding capability of smaller chucks. The master plate can be custom machined to fit any model chuck, making it a permanent universal fixture on any machine.When using this system, the transition from one job to the next simply requires bolting on a new size or configuration of segments

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

1ST MACHINE TOOL ACCESSORIES

United Kingdom

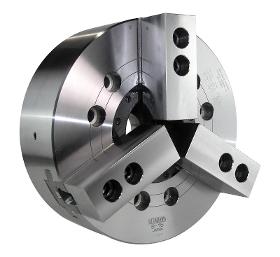

Compatible with large, readily available, range of jaws Allows for holding of larger components Upto 20% more speed and grip force than conventional chuck Standard Accessories AvailableKitagawa chucks are manufactured from high grade alloy steel. Three jaw wedge style power chucks deliver up to 20% more speed, gripping force and bore size when compared to conventional chucks. These larger style chucks provide the higher grip forces required for doing large work. B-A series chucks are supplied with a blank drawnut as standard with a set of T-nuts and adaptor plate.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Taper Ground for Minimal Runout Custom Adaptors are Available Available to suit range of spindle noses To Suit A2 Spindle Noses Standard spindle adaptors to suit power chucks with a 140mm recess. Range of adaptors to suit different spindles heads. High accuracy taper and outer diameter.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Taper Ground for Minimal Runout Custom Adaptors are Available Available to suit range of spindle noses To Suit A2 Spindle NosesStandard spindle adaptors to suit power chucks with a 170mm recess. Range of adaptors to suit different spindles heads. High accuracy taper and outer diameter.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Taper Ground for Minimal Runout Custom Adaptors are Available Available to suit range of spindle noses To Suit A2 Spindle NosesStandard spindle adaptors to suit power chucks with a 300mm recess. Range of adaptors to suit different spindles heads. High accuracy taper and outer diameter.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Taper Ground for Minimal Runout Custom Adaptors are Available Available to suit range of spindle noses To Suit A2 Spindle NosesStandard spindle adaptors to suit power chucks with a 220mm recess. Range of adaptors to suit different spindles heads. High accuracy taper and outer diameter.

Request for a quote

PORE FILTRATION

United Kingdom

Bespoke filter filtration systems are meticulously crafted to meet the unique demands of any industriy, offering a range of specialized options tailored to individual customer needs. Customisable Features Include: - Manifolded Configurations: Enable seamless integration of multiple housings, with options for duplexing using L-port, T-port, or butterfly valves. - Modular Design: Facilitates system expansion and customization. - Specialized Vessels: Custom-designed vessels tailored to specific applications, including inclined vessels. - Temperature Regulation: Optional heating jackets available for precise temperature control. - Surface Treatment Options: Choose from electropolished interior and/or exterior surfaces, interior coatings for chemical resistance, & polished internal finishes to specified Ra, - Integrated Monitoring: Complete with ports for installation of differential pressure gauges, enabling real-time monitoring facilitating timely servicing and filter changeout.

Request for a quoteResults for

Plating - Import exportNumber of results

24 ProductsCountries

Company type