- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- nozzle

Results for

Nozzle - Import export

JET FLOW TECHNOLOGIES UK LIMITED

United Kingdom

Based on the process requirement, a Multi Nozzle Ejectors can be designed five or seven nozzles type. Generally, one nozzle in the centre and remaining four or six nozzles are evenly circled around it. Multi Nozzle Ejectors can reduce the steam consumption by 15% to 20% as compared to Single Nozzle Ejectors when designed for the same conditions and it is more efficient to single nozzle ejectors. At times it is also considerably shorter in length when compared with same rated single nozzle ejectors.

Request for a quote

JET FLOW TECHNOLOGIES UK LIMITED

United Kingdom

Jet Flow Safety Valve represent the most advance technology in value designed for use in intermediate power boiler and organic fluid vaporizer service. Built in conformance to section I of the ASME boiler and pressure vessel code, all capacities am certified by the national board of boiler and pressure vessel inspector at 5% over pressure. Jet Flow Designed Safety Valve with Full Nozzle & hardened disc to minimize maintenance and increase seat life Open bonnet & Close bonnet both design have maximum set pressure 75 bar in Safety Valves. Material of Construction. Set pressure in psig or Kg/cm2 (g). Maximum inlet temperature. Allowable overpressure. ServiceSpecify either the media to be handled or the following physical properties or both. LiquidsSpecific gravity (Water = 1) GasesSpecific gravity (Air=1) VaporsMolecular weight (mixture of vapors. The average molecular weight) Back pressure, if any. Required capacity. Type of Endconnections. Preferred inlet size.

Request for a quote

JET FLOW TECHNOLOGIES UK LIMITED

United Kingdom

Jet Flow multi orifice desuperheater regulates the amount of injected water by varying the number of orifices during operation. The ensures that the spray water pressure remains constant at all loads and an excellent and almost uniform spray quality is achieved over the full operating range, thereby minimising the tendency of spray water to accumulate in the steam line. Opening of the orifices is regulated by the positioning of a piston operated actuator directly mounted on the desuperheater. This compact and simple design ensures no separate spray water Injection control valve is required.

Request for a quote

JET FLOW TECHNOLOGIES UK LIMITED

United Kingdom

Jet Flow fixed area nozzle desuperheaters are best suited for applications involving minimal load fluctuations. A fixed nozzle desuperheater utilizes high performance fixed geometry nozzles to reduce the steam temperature by directly injecting water inside the superheated steam flow. The water enters the main desuperheater body, passes through the spray nozzles and discharges into the steam line in the form of a fine mist.

Request for a quote

JET FLOW TECHNOLOGIES UK LIMITED

United Kingdom

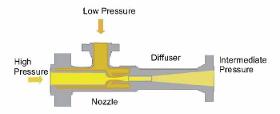

SingleStage Steam Jet Ejectors are based on the ejectorventuri principle. In operation, steam issuing through an expanding nozzle has its pressure energy converted to velocity energy. A vacuum is created and the high velocity of steam entrains air or gas and the mixture of gas and steam enters the converging end of the venturi, passes through the diffuser where its velocity energy is converted into pressure sufficient to discharge against a predetermined back pressure. Single stage steam jet ejectors are used to create vacuum covering 40 mm Hg. Absolute. Two Stage Ejector with Condenser The system is the assembly of two units whose construction is similar to single stage with inter condenser (direct contact type or surface type). Steam of the first stage is expanded through nozzle entrains the air or other gases and discharges them to diffusers at a higher pressure in the condenser.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Nozzle - Import exportNumber of results

5 ProductsCountries

Company type

Category