- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- grinding

Results for

Grinding - Import export

SPARX MACHINE TOOLS

United Kingdom

The Kuhlmeyer ZBS Twin Belt Grinding Machine is built for the roughing and finishing on welded edges, corners and surfaces on flat and mid-size workpieces out of steel, stainless steel, and aluminium, i.e. doors, frames, cabinets, housings, hoods, furniture parts, frame parts in automotive and aircraft – manufacturing, round bins, cylinders, heaters etc.

Request for a quote

THE TREE SURGERY COMPANY LTD

United Kingdom

Our experienced tree surgeons can remove your tree or hedge stumps, leaving you with peace of mind, knowing that all has been taken care of in a professional manner. Stump Grinding requires specialist equipment called a stump grinder. This is a high-speed disc-cutter with teeth that grind the stump into small chips – to below ground level. Our team are fully qualified and insured to handle this equipment and will use their expertise to meet your requirements. Grindings created by the process will stay on site, to mulch down to ground level. The Tree Surgery Company Ltd will leave the site clean and tidy after every job, leaving you to relax and enjoy your garden. The Tree Surgery Company are hard-working, with customer satisfaction being at the heart of their business. Contact us to discuss your Stump Grinding requirements using the contact form, or call us on 07540 333534 or 01752 213597.

Request for a quote

SHEERSPEED SHELTERS LTD

United Kingdom

This speed tent is ideally designed for all your butt fusion and Electrofusion welding needs. Standard Specification: - Translucent Waterproof PVC, reinforced, flame retardant - top of side panels and roof section – allowing maximum amount of NATURAL light into work area - Heavy-duty Waterproof PVC material (500gms) coated on both sides – 3/4 height of side panel - 100% waterproof seams - Wet storage properties - Smooth wipe clean surface - Robust die cast central joints - Centre joint cover protection (INTEGRATED) non conductivity & finger protection - Fibreglass framework - Rubber protected feet for extended product life - Non-conductive - 3off guy straps & tent pegs - All spare parts available - No loose components – integrated frame and cover

Request for a quote

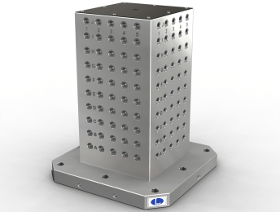

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Allignment Busing and Thread Hole for Quick Accurate Set-ups Ground Flat and Parallel Threaded Holes for Side-Location Cast iron gridded cube with mounting holes. Grid pattern with allignment bushes and threaded inserts for ease of set-up. Ground flat parallel and perpendicular for accuracy. Holes for side location to allow precise loading and setting up of the tombstone.

Request for a quote

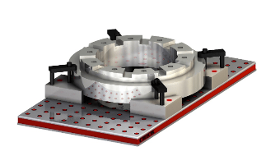

1ST MACHINE TOOL ACCESSORIES

United Kingdom

T-Slots to allow for Flexible use for Fixturing Products Ground Flat Five High Accuracy Location Holes Cast Iron Sub Plate to suit rotary table or indexer. T-Slot pattern to allow for easy flexible set-up of fixturing components. Ground flat with Locating Holes for precise loading and quick location.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Allignment Busing and Thread Hole for Quick Accurate Set-ups Ground Flat and Parallel Threaded Holes for Side-Location X-Shape allows for more side Clearance for Machining Cast iron gridded cross profile Tooling Column with mounting holes. Grid pattern with allignment bushes and threaded inserts for ease of set-up. Ground flat parallel and perpendicular for accuracy. Holes for side location to allow precise loading and setting up of the tombstone.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Sturdy Cast Iron Design Ground Flat and Parallel Modular quick change subplate to suit the BP13 modular cube. This plate is gridded to accept standard fixturing parts./

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

The Chick Indexer Sub System (ISS) combines the productivity and versatility of the Multi-Lok with a 4th axis rotary table The Chick Indexer Sub System (ISS) combines the productivity and versatility of the Multi-Lok with a 4th axis rotary table thereby converting a vertical machining centre to work like a horizontal providing: Obtain the benefits of a horizontal CNC machine on a vertical CNC machine, by using CHICK’s Indexer Subsystem (ISS). Utilize the indexer you have and marry it to one of CHICK’s Multi-Loks. The ISS gives you the ability to machine on mulitple part sides with only one clamping, thereby decreasing the cycle time and increasing accuracy of your part. Obtain the benefits of a horizontal CNC machine on a vertical CNC machine, by using CHICK’s Indexer Subsystem (ISS). Utilize the indexer you have and marry it to one of CHICK’s Multi-Loks. The ISS gives you the ability to machine on mulitple part sides with only one clamping, thereby decreasing

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Machinable to accept required hole pattern Ground Flat Five High Accuracy Location Holes Cast Iron Sub Plate to suit rotary table or indexer. Plain to allow for machining of hole patterns and features required for special jigs or fixtures. Ground flat with Locating Holes for precise loading and quick set-up.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Allignment Busing and Thread Hole for Quick Accurate Set-ups Ground Flat Five High Accuracy Location Holes Cast Iron Sub Plate to suit rotary table or indexer. Grid pattern with allignment bushes and threaded inserts for ease of set-up. Ground flat with Locating Holes for precise loading and quick location.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

A Chick Workholding Foundation Plate is tailored to fit the machine’s specifications. A standard grid pattern to simplify designing, cataloguing and utilisation of fixtures, providing consistency and repeatability to set-ups. Length and width tailored to the machine’s work envelope. Precision ground cast iron to 35mm thick. 50mm spaced holes, drilled and tapped, for use as both location and hold down. Sealed with chip plugs. An alpha-numeric labelling system. Minimises set up time from workholding system to system. Machine interface mounting holes, customised for each machining centre.

Request for a quote

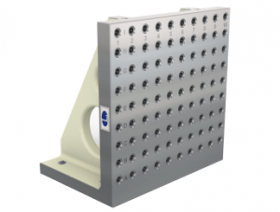

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Allignment Busing and Thread Hole for Quick Accurate Set-ups Ground Flat and Parallel Cast iron gridded angle plate .Grid pattern with allignment bushes and threaded inserts for ease of set-up. Ground flat parallel and perpendicular for accuracy. To suit verticle or horizontal machining centre applications.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Allignment Busing and Thread Hole for Quick Accurate Set-ups Ground Flat and Parallel Cast iron gridded angle plate .Grid pattern with allignment bushes and threaded inserts for ease of set-up. Ground flat parallel and perpendicular for accuracy. To suit verticle or horizontal machining centre applications.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Machinable to accept required hole pattern Ground Flat and Parallel Locating Holes for easy Set-Up Cast iron plain fixture plate with mounting holes. Plain to allow for the machining of hole patterns and features required for specific fixtures. Ground flat parallel and perpendicular for accuracy. Two dowel holes allow for precise loading and setting up of the fixture plate.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Machinable to accept required hole pattern Ground Flat and Parallel Locating Holes for easy Set-Up Cast iron plain fixture plate with mounting holes. Plain to allow for the machining of hole patterns and features required for specific fixtures. Ground flat parallel and perpendicular for accuracy. Two dowel holes allow for precise loading and setting up of the fixture plate.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Allignment Busing and Thread Hole for Quick Accurate Set-ups Ground Flat and Parallel Locating Holes for easy Location Cast iron fixture plate with mounting holes. Grid pattern with allignment bushes and threaded inserts for ease of set-up. Ground flat parallel and perpendicular for accuracy. Two dowel holes allow for precise loading and setting up of the fixture plate.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Rigidity - The new Boss HD (Heavy Duty) structure guarantees the barfeed absorbs a larger quantity of vibration Operator interface - The new enhanced operator interface has new user friendly functions. Touch screen is available Non productive times - Bar change and feeding times have been drastically reduced increasing productivity Magazine capacity - Several options available to increase capacity for longer unattended production The BOSS 552 HD is an automatic bar feeder for bars with diameters between 5 and 51 mm, ideal for working with fixed headstock and sliding headstock lathes, available for bar lengths from 700 to 6,380 mm. It guarantees the maximum reliability without any compromises. * Based on indicative data. Material, Bar Length & Parameters can significantly affect this time

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Adapt standard expanding mandrels for blind holes Compatible with metric ID Xpansion clamps Milling and turning versions available Manual actuators for use with the Miteebite range of ID Xpansion clamps. These Actuators are specifically designed for gripping the ID of blind holes but may also be incorporated in many applications that require a straight draw actuated 90 degrees from the drive screw. They are capable of gripping on bores ranging from 4.1mm to 35.3mm using our standard ID clamps. Both styles of Actuators come completely assembled with the heat-treated cylinders tapped for the following clamp drive screws: M2, M4, M6, M8, M10 and M12.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Allignment Busing and Thread Hole for Quick Accurate Set-ups Ground Flat and Parallel Threaded Holes for Side-Location Cast iron gridded cube with mounting holes. Grid pattern with allignment bushes and threaded inserts for ease of set-up. Ground flat parallel and perpendicular for accuracy. Holes for side location to allow precise loading and setting up of the tombstone.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Two Magazines in One - A step by step magazine for material up to 6mm and a gravity magazine for larger material Flexibility - Re-tooling takes minutes thanks to the use of snap-in guide channels High Performance - Works with closed calibrated channels ensuring high speeds with reliability, precison & silent operation Headstock Synchronicity - Fitted with a mechanical system that give both reliability, precision & a reduction in idle times The Elite is a premium bar feeder, simple to use. It is designed to meet the needs of those who are looking for the best possible performance and reliability, accurate selection of thin bars, adaptability when changeovers are needed, and a guarantee of rigidity even for the most challenging machining applications. * Based on indicative data. Material, Bar Length & Parameters can significantly affect this time ** Max Capacity

Request for a quote

SPARX MACHINE TOOLS

United Kingdom

18" x 6" CAPACITY. POWER RISE AND FALL TO WHEEL HEAD. DUST EXTRACTION. OPTI DRESS PANTOGRAPH WEIGHT 850 KG

Request for a quote

SPARX MACHINE TOOLS

United Kingdom

The MCSB/2B-900 is a 900mm wide belt and brush/roll dry working Grindingmaster that is equipped with powerful motors allowing it to process the toughest and heaviest jobs around. R.P.M.1500 Hp/Kw15 + 7.5 kW Typical process applications covered by this machine: Stock removal of multiple individual parts and sheet materials Grain and scratch brush finishing of any material. Sizing and finishing of parts and sheet materials Deburring punched, nibbled, sheared or laser-cut sheet metal parts. Calibrating or keying carbon, rubber, wood or other soft materials.

Request for a quote

SPARX MACHINE TOOLS

United Kingdom

Abrasive belt grinder for the cleaning of corner welds and for the creation of spokes on rectangular pieces such as boxes, at double speed it allows to work angles of maximum height 145 mm on a support surface adjustable in height and inclination. Spoking system with two-roller fork on which abrasive belt slides, the adjustable oscillation of the rollers both in the angle and in the fulcrum allow to obtain the desired radius from R = 1 to R = 10 or cleaning with a sharp edge. The adjustment of the plane by means of a handwheel guarantees the best exploitation and correct bending of the belts of adequate width for the height of the piece.

Request for a quoteResults for

Grinding - Import exportNumber of results

24 ProductsCountries

Company type