- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- industrial%20machinery

Results for

Industrial%20machinery - Import export

DRALLIM INDUSTRIES LIMITED

United Kingdom

The Rotary Selector Valve or RSV, is a small bore multiport, multibank rotary poppet system suitable at pressures ranging –1 +10 Bar, Fluid Temperature 85°C (185°F) . It is a relatively simple & therefore extremely reliable unit, based on a modular design & as such configurable for a multitude of applications. It is custom built from stock parts. The body is manufactured in brass or stainless steel, both having stainless spindles & they can have stems and seals in differing materials to suit the media being used. Each bank of the valve is pneumatically independent but linked by a common central spindle, enabling separate air paths to be controlled concurrently; each output is effectively a valve. The RSV (once also known as the PIV or Pneumatic Interlok Valve) can incorporate an integral electrical rotary switch which allows fluid & electrical circuits to be controlled simultaneously or can be used simply to provide positional indication remotely at the control centre.

Request for a quote

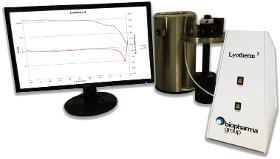

BIOPHARMA GROUP

United Kingdom

Rocket Synergy 4D is for drying single large volumes of solvent, from a few litres up to approximately 100 litres. The system can also be used for a single batch of up to 5 litres. Rocket Synergy 4D provides fast, safe evaporation for solvents with a boiling point of up to 165°C (DMF) and can easily dry aqueous samples. Automatic evaporation of volumes up to 100 litres Eliminates bumping or foaming Easy vessel manipulation with no glassware to handle Safe, easy product recovery and system cleaning

Request for a quote

BIOPHARMA GROUP

United Kingdom

Frozen state solutions are a critical product stage or end product in a variety of industries, including freeze drying, pharmaceuticals, food storage and biotech. The Lyotherm3 combines electrical and thermal techniques. This unique dual analysis adds a new dimension to the data of this critical stage. Impedance Analysis (Zsinφ) is a fixed frequency dielectric analysis providing an indication of the sample tracks molecular mobility, including events not picked up by thermal methods like DTA or DSC Differential Thermal Analysis (DTA) measures the difference in temperature between a sample and a reference, highlighting exothermic and endothermic events e.g. crystallisation, eutectic melting and glass transitions Combining DTA and Impedance analysis means Lyotherm is more sensitive to changes within the frozen structure than other exclusively thermal techniques.

Request for a quote

BIOPHARMA GROUP

United Kingdom

Kinematics & Controls Corporation’s compact modular powder filling systems have proved to be popular in environments where not only precise material dosing is required, but also in areas where companies seek to make the process more efficient, maximising potential product throughputs. Powder is picked up by vacuum and compacted to a constant density within a cylindrical fill chamber. It is subsequently dispensed by the application of low-level, positive-pressure air. The use of a pre-defined vacuum force, compressing the powder sample to a uniform/ even density is the key to achieving the high level of repeat dose accuracy. Cumbersome, time-consuming, hand-weighing is thus eliminated. A wide range of standard gun sizes and filters with various porosities are offered for use with the variety of powders and container sizes which the customer’s process might demand. A custom, 8-up, Micro-Well kit can also be specified, to streamline the filling of 96-cavity well plates.

Request for a quote

BIOPHARMA GROUP

United Kingdom

The Series 3 HT evaporator range from Genevac represents the ultimate in solvent removal technology. Genevac-014 A Solution for High Throughput Evaporation Genevac HT series evaporators are the ideal solution for parallel evaporation bottlenecks in high throughput and production laboratories having high performance and high sample capacities. The unique design of the multi-layer rotor ensures efficient use of valuable laboratory bench space as well as high performance and high throughput evaporation. This proven design has now been updated with the latest version, the Series 3.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

BRILLOPAK

United Kingdom

High specification automatic machines to dispense or stack crates and trays onto manual and automatic packing lines. Reliable 600mm x 400mm retail crates Complete pallet of accumulation FEATURES & BENEFITS: -Small Footprint. -Heavy Duty. Robust construction for 24/7 usage and reliability. -Reduced labour cost in preparing crates pre/post production line. -Reduced health and safety risk through repetitive handling of crates. -Consistent throughput speed increases overall packing efficiency. ** Click for more **

Request for a quote

BRILLOPAK

United Kingdom

The BRILLOPAK P160 Unipick provides high-speed, accurate but gentle packing of tray seal, flow wrap and VFFS products into trays, cases and boxes. Ideal for packing fruit and meat. Multiple products Multiple patterns Delicate product placement FEATURES & BENEFITS: -Flexibility of operation. Single pick means one system can support multiple product types with multiple patterns. -Extreme accuracy of placement into crate ensures first class presentation on supermarket shelf. -Delicate handling: Due to single pick, individual products are placed gently and accurately into position meaning no damage to product or packaging. -No complex collation requirement: Less to go wrong. -Simple to operate, manage and maintain. ** Click for more **

Request for a quote

BRILLOPAK

United Kingdom

Designed for 24/7 operation this machine dispenses pallets and accumulates a loaded pallet stack outside the cell. Can be floor loading or over conveyor. Up to 30 cases or crates per minute Small footprint Enhanced Safety Features FEATURES & BENEFITS: -Specialist Brillopak robot heads. Run multiple products with no tooling changeover. -No manual heavy lifting. -System automatically lifts pallet stacks from floor and places loaded pallet stack onto floor for use with hand trucks. -Simple to operate by unskilled staff. -Entire system built and fully tested in our factory. Delivered in 2 pieces for very fast commissioning on site. ** Click for more **

Request for a quote

BRILLOPAK

United Kingdom

The dual cell machine has a small footprint and is designed for cases, boxes, trays, and bags. Brillopak specialist end effectors will handle multiple case or bag sizes, as well as all current supermarket rigid/collapsible tray types without the need for tooling changeovers. Continuous palletising Multiple products and layer patterns Additional safety gate between cells FEATURES & BENEFITS: -Compact size. -Specialist Brillopak robot heads. Run multiple products with no tooling changeover. -Simple to operate by unskilled staff. -Easy to programme new patterns in-house. -Enhanced safety features. ** Click for more **

Request for a quote

BRILLOPAK

United Kingdom

Our Flexible Robotic Palletiser is the smallest footprint and is designed for cases, crates and bags. Multiple products Multiple patterns Easy to program FEATURES & BENEFITS: -Compact: Smallest palletiser for crates. -Specialist Brillopak robot heads. Run multiple products with no tooling changeover. -Simple to operate by unskilled staff. Select the product and press start. -Easy to maintain. Simple plug in, plug out of new parts. -Enhanced safety features. ** Click for more **

Request for a quote

BRILLOPAK

United Kingdom

An optimised semi-automatic packing machine that puts you back in control of pack line speed. Reduced Labour Cost - Semi Automatic Packing Machine Increased product throughput Minimised quality issues FEATURES & BENEFITS: -Increases line speed, semi automatic packing machine. -Ergonomically designed for optimal performance. -Handles crates or cardboard trays. -Minimises health risks associated with repetitive working. -Tray infeed at rear or system minimises clutter along the line. ** Click for more **

Request for a quote

BRILLOPAK

United Kingdom

The BRILLOPAK C111 robotic packaging system provides high-speed packing of products into crates and cases. Due to the vertical movement of the robotic arm, the case packing system is able to pack to a depth of 800mm providing the versatility to pack to multiple container types. Ideal for case packing, tray packing and seal punnets. Over 150 packs per minute Precise product placement Multiple products and layer patterns FEATURES & BENEFITS: -High speed case packer: Up to 150 packs a minute. Multiple products with no tooling changeover. -Delicate handling: Using soft flexible grippers or vacuum cups with independent vacuum generators, no damage to product in pick process at high speed. -Very small footprint. -Can pack products up to 5kg weight. -Simple to operate, manage and maintain. ** Click for more **

Request for a quoteResults for

Industrial%20machinery - Import exportNumber of results

13 ProductsCountries

Company type