- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- product handling

Results for

Product handling - Import export

ACCRAPLY EUROPE LTD

United Kingdom

The new Sirius 100 range of labelling systems are specifically designed to meet the modern demands of today’s fast-moving, highly flexible production lines. Accraply has transformed the technology-driven linear labelling of its high-speed systems into an extremely cost effective single and twin head labelling solution. This user-friendly, rapid changeover labelling system can serve the contract packaging, food, and automotive industries and can transform your production line with its highly flexible product handling options and controls. This Sirius pressure sensitive labelling machine has superior product handling options and controls that allow for a wide range of applications due to its Servo Axes. Synchronized for perfect speed matching on label applications, it is a highly flexible, streamlined machine to add to your production line. Learn more about the benefits of the Sirius 100 Pressure Sensitive Labelling System below.

Request for a quote

INDUSTRIAL BRUSHWARE LIMITED T/A IBEX INDUSTRIAL BRUSHES

United Kingdom

Punch Filled (or Staple set) brushes are produced by stapling tufts of wire, filaments or natural fibres securely into a plastic, wood, steel or aluminium body to create the desired configuration to suit the cleaning application. The style of the brush, which can be either a roller, flat, disc or block together with the pattern of the tufts determines the cleaning or product handling performance required. Each application will need a desired result and we can advise you on which style of brush may have the best features to achieve this.

Request for a quote

INDUSTRIAL BRUSHWARE LIMITED T/A IBEX INDUSTRIAL BRUSHES

United Kingdom

Punch Filled (or Staple set) brushes are produced by stapling tufts of wire, filaments or natural fibres securely into a plastic, wood, steel or aluminium body to create the desired configuration to suit the cleaning application. The style of the brush, which can be either a roller, flat, disc or block together with the pattern of the tufts determines the cleaning or product handling performance required. Each application will need a desired result and we can advise you on which style of brush may have the best features to achieve this.

Request for a quote

WIRE BELT COMPANY LTD

United Kingdom

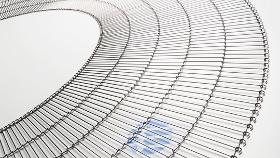

Field-proven and dependable Flex-Turn® units gently convey products in process around corners while maintaining proper product alignment. They offer the tightest level transfer and smallest inside turning radius available with an open mesh belt. Smooth, non-collapsing product handling minimises potential damage to delicate products. The compact design solves tight production line space problems.

Request for a quote

WIRE BELT COMPANY LTD

United Kingdom

Flex-Turn® conveyor belts gently convey products in process around corners while maintaining proper product alignment and spacing. They offer the tightest level transfer and smallest inside turning radius available. Smooth product handling minimises potential damage to delicate products. Our Flex-Turn® conveyor belts are specifically designed to work with our Flex-Turn® conveyors. Like all of our Flat-Flex® belts, Flex-Turn® belts are easy-to-clean and maintain.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

LAYTON TECHNOLOGIES

United Kingdom

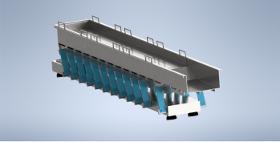

Single stage IPA solvent vapour component drying machine for critical applications – link to the Vapour Dryer whitepaper. - Does not require Zone 1 & 2 area – can operate in standard production environment. - Marangoni alternative - Water displacement technology. - PLC controlled for ease of use. - Vapour zone - Freeboard area - Ease of maintenance - Flexible process with ease of use via HMI - Retain your existing validated process - Fire protection and suppression systems. - Flammable vapour detection and handling facilities. - Solvent handling to facilitate the safe filling and draining of the process fluids. - Solvent re-processing system. - Internal automated product handling. - Exhausted environmental enclosure. - Primary cooling coils. Cooling water to be supplied by customer facilities or a local chiller can be supplied as optional. - Sealed sliding tank lid. - Manufactured entirely from stainless steel. - Etc. ** Click for more **

Request for a quote

INTEGRATEDAIR SYSTEMS

United Kingdom

Wherever an industrial process produces waste, we can design systems to capture and remove it. The waste will then simply be taken away to be recycled or disposed of. Our expertise in this process is trusted for many different medias and industries such as food and beverage, paper, corrugated card or packaging and containers. Efficient industrial waste extraction in the workplace is critical to the safety of your working environment, and with over 100 years of combined engineering expertise behind us, we’re the ones to call.

Request for a quote

VCSP LTD

United Kingdom

VCSP's Vibratory Laning and screening Conveyors are the epitome of precision and efficiency. Expertly engineered, they ensure exact product laning and screening capabilities. By harnessing the power of vibration, these conveyors align products perfectly. Customizable to diverse needs, they fit various product types and capacities. Key features include adjustable vibration settings, a range of surface finishes, and energy-efficient designs. Built for durability, they promise longevity even in demanding industrial settings. Their user-friendly design ensures easy maintenance, while their adaptability allows for integration into existing production lines. Ideal for robotic pick and place, automated assembly, packaging lines, and quality control, VCSP's Vibratory Laning Conveyors are the answer to precise product handling and alignment

Request for a quoteResults for

Product handling - Import exportNumber of results

9 ProductsCompany type