- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- processing machines

Results for

Processing machines - Import export

CNC CREATIONS

United Kingdom

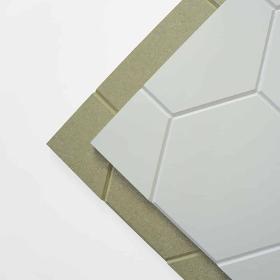

Currently only available in 9mm. Other thicknesses available upon request. Please note, the machining process of these panels may cause the material to bow.

Request for a quote

BALABAN54 MAKINA DIS TIC LTD STI

United Kingdom

Cream Processes Unit By means of this tank the cream is pasteurised and decreased to maturing temperature. Culture is added at this temperature and maturing is continued.

Request for a quote

SWANWICK FOODSERVICE EQUIPMENT LTD

United Kingdom

Slice, dice, chop, spin, mix, peel, wrap. You name it, it's here. Everything you need for food processing and preparation. Butchers and meat processing equipment from Mainca, Electrolux, Boston Atlas and Talsa.

Request for a quote

M.R. MACHINE KNIVES LTD.

United Kingdom

We are capable of producing a variety of blades for food processing and slaughtering machines. Offering blades in the best quality stainless steel, we are able to meet stringent requirements put in place by our customers to ensure our blades are food-safe. We recognise a lot of OEM reference codes, but we are also able to reverse engineer our blades from samples, or from your own technical drawing. Applications for these type of blades could include fish slicing, breaking meat, cutting meat, slaughtering animals, trimming meat, skinning fish, slicing meat and processing poultry all the way through the production line.

Request for a quote

RIDAT

United Kingdom

Ridat’s Automatic Vacuum Forming Machine range with Double Heater (AVF) is designed for consistent production of all commonly used thermoformable material of up to 12 mm thickness. Robust construction with an automatic vacuum forming cycle and user-friendly touch screen control of all processing features. Key machine features include: Top and bottom heaters ensure balanced heat distribution with minimal material stress. The dual ceramic heaters also enable a variety of material sheet types (such as PVC, PP, PS, APET, GPET, HDPE, ABS) to be vacuum formed. Clamp frame and mould table are both raised by four cylinders and guided by rack and pinion mechanism for smooth and parallel movement Fully sealed mould chamber to maintain vacuum pressure and facilitate pre-blow and bubble Photo electric sensor to control sheet sag and bubble height High capacity vacuum reservoir and pump for instant vacuum supply High velocity turbo fans to cool the vacuum formed sheets CE Mark

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Processing machines - Import exportNumber of results

5 ProductsCountries

Company type