- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- pipelines

Results for

Pipelines - Import export

STALEVAR COMPANY LLC

United Kingdom

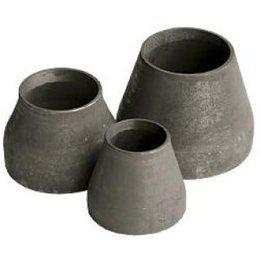

Pipeline parts used in the construction of pipelines are also called pipeline fittings. In essence, these are connecting products used in the installation of pipelines for various purposes water pipelines, gas pipelines, oil pipelines and intended for use when turning, bending, tilting, tilting, changing the diameter of the pipe and in case of temporary non use of the pipeline. Enamel coating can provide protection against corrosion. It is customary to refer to the types of pipeline fittings transitions, plugs, couplings, bends, tees, flanges, etc. The main details of the pipeline You can contact us by mail - marketing@stalevar.com or by phone +380675624220.

Request for a quote

OFFSHORE PRODUCTS INTERNATIONAL LTD

United Kingdom

Flanges SCH 10S through XXS (Special walls) Ratings 150# through 2500lb ANSI, API, DIN and BS Standards All manufactured to equivalent forged material specifications as above. Special Swivel Ring Sets and API 10,000and 20,000 Rated Flanges also manufactured to existing standards or client requirements.

Request for a quote

OFFSHORE PRODUCTS INTERNATIONAL LTD

United Kingdom

BW Fittings SCH 10S through XXS (Special walls) Seamless and Welded Construction 90 LR Elbows, 45 Elbows, Equal Tee’s Con Reds, Ecc Reds, Caps and Stub Ends Sizes available up to 8″ NB Seamless and 48″ NB Welded All manufactured in equivalent materials as above and to ANSI B16.9. Special 3D and 5D bends manufactured to order.

Request for a quote

OFFSHORE PRODUCTS INTERNATIONAL LTD

United Kingdom

Seamless line Pipe SCH 10S through SCH XXS (special walls also available) Materials include: Carbon/High Yield to ASTM A106 GR B, A333 GR 6, API 5L X52/60 Stainless Steel to ASTM A312 TP 304L, 316L and 321 Duplex Steel to ASTM A790 UNS 31803, UNS 32750 and UNS 32760 Copper Nickel to 90/10 UNS 7060X to EMUA 144 6 MOLY to ASTM A312 UNS 31254

Request for a quote

INDUSTRIAL BRUSHWARE LIMITED T/A IBEX INDUSTRIAL BRUSHES

United Kingdom

Pipeline Brush

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

STALEVAR COMPANY LLC

United Kingdom

Pipeline fittings are installed when the direction of the pipeline changes during the installation process. Elbows are made of steel, steel with increased corrosion and cold resistance, alloy steel. Types of bends Steeply curved, seamless bends; Stamp welded steeply bent bends; Welded sectional bends; Cold rolled bends

Request for a quote

ABFAD LTD

United Kingdom

A new method of pipeline corrosion protection, which provides the answer to both elimination and monitoring of corrosion, has recently been developed Abfad Limited. PIPEVAC® is an innovative pipe protection system which has been developed to eliminate external corrosion by creating a vacuum around a pipe. With the creation of an external vacuum it is now possible to monitor the pipeline in sections, which enables our clients an opportunity to investigate any alarm and take action to protect their assets and the environment from pollution. An internal or external breach of the pipe will activate an alarm as vacuum pressure will not be able to be maintained. PIPEVAC® also prevents against CUI (Corrosion Under Insulation) as the integrated vacuum system prevents moisture and oxygen from attacking the external surface area of the pipe, thereby preventing any of the conditions for corrosion to occur.

Request for a quote

OFFSHORE PRODUCTS INTERNATIONAL LTD

United Kingdom

Developing method statements and procedures for below: We offer turn-key EPIC Oil & Gas project execution, including all procedures, HSE, testing, verification and certification services for: Subsea IRM – Inspection, Repair and Maintenance including: • 3D survey • Pipeline repair • Maintenance Construction & Decommissioning works which includes: • Isolation & Barrier testing • Spool Installation • Cable lay • Pipe lay • Shore pulling • Trenching • SCM Changeout • Connection and Pressure testing • Pre-commissioning • J-Tube & Riser Clamp Installation • Flexible Flowline and Jumper Installation • Mattress & Grout Bagging

Request for a quote

JME LTD

United Kingdom

JME Advanced Inspection Systems has a reputation as the market leader for the design and manufacture of high quality inspection systems, this includes our range of Pipeline Crawlers used by the ‘Non-Destructive Testing’ industry. For over 30 years, JME Pipelines Crawlers have been continually improved and updated to produce panoramic radiographs of the highest quality. Our range of systems are designed to inspect circumferential butt welds in new pipelines, such as oil and gas transmission pipelines, from 6” to 72” (15.24cm to 183cm). As a self-contained and self-powered exposure vehicle, they are ideal for a vast range of NDT applications both on and off shore. Over the past 30 years, JME has built its reputation on innovation, quality, service, and commitment to our clients. As a company, JME thrives on customer satisfaction, which is why many of our customers have been using our services for nearly 30 years.

Request for a quote

FORTRESS TECHNOLOGY (EUROPE) LTD

United Kingdom

The precision detector utilizes digital signal processing technology with high sensitivity levels to clearly identify the presence of a metal contaminant. Ferrous, non-ferrous and stainless steel fragments are successfully detected, and when equipped with a reject valve, rejected from production. A variety of valves, pipe materials and fittings are available to easily integrate into existing systems; all standing up to high pressure, temperature and washdown environments.

Request for a quoteResults for

Pipelines - Import exportNumber of results

11 ProductsCountries

Company type