- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- metal sheet

Results for

Metal sheet - Import export

ALPHA MANUFACTURING

United Kingdom

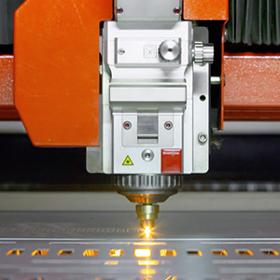

Utilising the latest in Fibre Laser Cutting technology Alpha Manufacturing are able to offer a versatile laser cutting service in various material types including; Mild Steel, Coated Steels, Stainless Steel, Aluminium, Wood and Plastics. We currently operate one Co2 Bystronic Laser, one Bystronic BySprintFiber 4020 machine and our latest addition to our Laser service, the Trumpf Trulaser 3030 fibre machine. Fibre optic laser is the latest technology in laser cutting, with complete accuracy and ultra high-speed cutting (whilst also using fewer power resources than traditional lasers, meaning reduced costs to the customer).

Request for a quote

DEKS INDUSTRIES EUROPE

United Kingdom

DEKS FastFlash Solar Flashing, a flexible flashing for the bottom edge of in roof solar installations. Its a fully adhesive butyl backed flexible flashing used for sealing the bottom edge of in roof solar installations, creating a wind and water tight solution which is easier to apply than many of the OEM solutions. The product stretch enables it to seamless follow the contours of the roof. Available in black, light grey & dark grey in various widths.

Request for a quote

STALEVAR COMPANY LLC

United Kingdom

Hot rolled channel GOST 8240 97 is used for buildings requiring a large load on strength, as well as in production and in everyday life. Indispensable for mechanical engineering, barriers, construction of houses and stairs, sheds and canopies, car frames and other machines ( GOST 19425 74 special channel), partitions, car building ( GOST 5267.1 90 special channel ) and other supporting structures and structures , all kinds of frames , parts, knots. Assortment and dimensions of the channel The channel in the form of manufacture is U shaped, U shaped, increased accuracy A and ordinary (standard) accuracy B. The length of the channel in accordance with GOST is 6 12 m and the size of the shelf is from 50 mm to 300 mm. With an appropriate volume of the order, it is possible to manufacture metal products to order . The volume of the order is not limited up to the carriage standards. You can contact us by mail - marketing@stalevar.com or by phone +380675624220.

Request for a quote

STALEVAR COMPANY LLC

United Kingdom

Galvanized sheet is made from flat rolled sections by the method of uniform zinc spraying to ensure its durability. According to the design, the product is made smooth of small thicknesses; it is further modified into a perforated and corrugated sheet on special machines, which is later used for the construction of barriers, roofs, gazebos, etc. Smooth galvanized sheet is widely used in mechanical engineering and in everyday life. It is used to make water tanks, cisterns, barrels, trailers, fences, cars, wagons, water transport, carts, shovels, road signs, playgrounds, etc. Galvanized corrugated sheet is intended for the manufacture of pedestrian areas, crossings, ladders, footrests, steps. The galvanized product is produced in rolls and in sheets with a width of 1000 to 1500 mm, a length of up to 2500 mm with a wall thickness of 0.3 2 mm You can contact us by mail - marketing@stalevar.com or by phone +380675624220.

Request for a quote

STALEVAR COMPANY LLC

United Kingdom

I beam (I beam) is a type of metal product used for supporting structures and floors of automobile and railway bridges, tower, bridge and gantry cranes, crane girders, supports and other supporting structures. The main task of the beam is to carry the strength force to all types of permissible loads. Of all the presented type of metal products, it is the most durable. Depending on the bearing load, the selection of the beam is made. Do not overload the metal structure with the permissible size of the beam, as it may become unjustifiably expensive and difficult to transport. There are certain formulas and criteria for the selection of the required brand and size of the beam. If necessary, our qualified specialists will help you as much as possible to select the required sizes of metal products. The length of the I beam, as a rule, is 12 meters or more, and the width of the flange is from 10 to 50 cm. You can contact us by mail - marketing@stalevar.com or by phone +380675624220.

Request for a quote

STALEVAR COMPANY LLC

United Kingdom

Холодно и горячекатаные листы и рулоны от 0,35мм до 200мм из углеродистой низко и высоколегированной стали. Листовой прокат имеет самый широкий спектр применения: тяжелое машиностроение, строительство, штамповка и кровля зданий.

Request for a quote

STALEVAR COMPANY LLC

United Kingdom

Profiled sheet is one of the most demanded types of rolled metal, which is used in the construction industry. Profiled sheeting is represented by roof and wall types of profiles. Manufacturing of a profiled sheet involves the use of ultra modern precision equipment. Cold rolled steel is processed by rolling shafts that create the geometry of the profiled sheet. You can contact us by mail - marketing@stalevar.com or by phone +380675624220.

Request for a quote

STALEVAR COMPANY LLC

United Kingdom

Холодно и горячекатаные листы и рулоны от 0,35мм до 200мм из углеродистой низко и высоколегированной стали. Листовой прокат имеет самый широкий спектр применения: тяжелое машиностроение, строительство, штамповка и кровля зданий.

Request for a quote

ALPHA MANUFACTURING

United Kingdom

Our latest machine is the VTC-300 CII which is a highly versatile vertical machining centre with a large 2000 mm table cross dimension and high-speed rapid traverse of up to 36 m/min. Productivity and efficiency are greatly improved as the machine work envelope is separated into 2 work areas. This allows the machine to be in cycle, in one work area, while a part is being set up in the other work area.

Request for a quote

ALPHA MANUFACTURING

United Kingdom

Alpha offer a range of folding solutions depending on the needs of our customers including manual, automated and robot folding machines. Our manual folding line consists of 6 manned Amada press brakes capable of folding mild steel, coated steels, stainless steel, aluminium and alloys upto 4100mm in length. Automated folding offers optimised machine cycle times through automated tool selection and simultaneous component load and unload. Parts are programmed offline allowing the machine to run components whilst the next is programmed ready for production. We currently operate an automated TBZ panel folding line as well as completely automated robot folder.

Request for a quote

ALPHA MANUFACTURING

United Kingdom

Our plant is fully automated and employs industry leading pre-treatment process OXSILAN®. OXSILAN® is a new metal pre-treatment technology that is free from hazardous chemicals and provides superior corrosion resistance for a wide range of metal substrates. OXSILAN® replaces traditional iron and zinc phosphate products. The products provide a superior ecological profile. OXSILAN® is suitable for metal surface treatment, e.g. cold rolled steel, aluminium, zinc coated steels, as well as multi-metal applications.

Request for a quote

ALPHA MANUFACTURING

United Kingdom

Alpha Manufacturing offers a range of welding solutions including MIG welding, TIG welding, robotic welding, projection welding and spot welding for aluminium, mild steel and stainless steels. Our highly trained weld team are some of the best in the industry and our quality is second to none. Robotic Welding Alpha Manufacturing's installation of a robotic welding has increased our capacity to offer high accuracy weld detail in volume as well as 100% product repeatability. Robotic Welding is the perfect solution for customers who require high volume, highly accurate, repeatable products. Alpha's robot welder boasts high-end features such as Cold Metal Transfer technology to eradicate spatter and reduce burn-through and distortion. The Robot also comes equipped with Seam Finding technology to ensure the robot always welds true to joining parts.

Request for a quote

ALPHA MANUFACTURING

United Kingdom

With a versatile punch/ laser combination service, Alpha are able to offer complete flexibility to produce punch details such as louvres and ribs alongside complex lasered profiles and etches in one process. The benefits of Punch/ Laser combination are that production time is dramatically reduced by combining the two processes. Costs savings are also made as complex and costly tooling is not required.

Request for a quote

ALPHA MANUFACTURING

United Kingdom

Alpha Manufacturing utilise the latest Pullmax and Trumpf punching machinery to offer unbeatable productivity, reliability and flexibility as well as ultimate efficiency through automated “lights out” production. We are able to perform 24-hour operation of unmanned CNC Punching machines which gives us greatly improved productivity with considerable quality improvements. Customers benefit from outstanding process consistency, offering industry leading punching standards.

Request for a quote

ALPHA MANUFACTURING

United Kingdom

Alpha Manufacturing have an experienced design team who are dedicated to working closely with our customers to ensure that every part we manufacture is exactly to clients' requirements. Using the CAD software and design techniques, our NPI (New product introduction) department ensure that all parts are manufactured in the most efficient and cost effective way, without compromising on quality through the manufacturing process.

Request for a quote

WWW.MARCHANDISE-PRO.COM

United Kingdom

Professional equipment for Food Truck! cooked smoke extraction cooking chips creperie crepe maker snack plate snacker hood pizza pizzeria restaurant rotisserie restaurant chip shop ice cream shop Greek Turkish Turkish kebab for your takeaway Decorative and hygienic aluminum plate covering. 304 L food-grade stainless steel sheet wall cladding wall protection anti shock plate kitchen equipment chr food-truck ribbed aluminum anti-slip floor positive and negative cabinet glass rear bar glass cabinet stainless steel cabinet stainless steel hood showcase Counter charcoal grill dimmer ventilation turret activated carbon box workplan gas or electric stove waffle iron anti-slip floor gastro tray plancha gastro tray glazed refrigerated kit freezer freezer slicer meat grinder buffet hand shower sink open and closed wall cupboard trash can panini grill smokehouse Don't hesitate to contact us for more information or for custom order. MARCHANDISE PRO

Request for a quote

BIRMINGHAM SPECIALITIES LIMITED

United Kingdom

For many years now we have delivered unrivalled presswork and metal forming capabilities, and from our Birmingham based headquarters we continue to supply the quality and precision that you and other professionals servicing customers in other market sectors need to a high specification and at the most competitive price point.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

METALOFFCUTS

United Kingdom

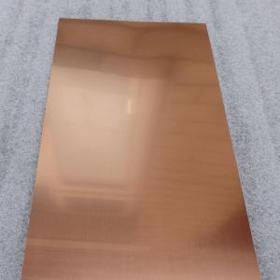

High quality copper sheet metal, typically Grade C106, (CW024A) Peal-able plastic coating to one side Worldwide delivery

Request for a quote

METALOFFCUTS

United Kingdom

High quality zinc sheet - European manufacture EN988 Suitable for Table Tops, Bar Tops, Roofing

Request for a quote

CTT TECHNOLOGY (UK) LIMITED

United Kingdom

In the medical field, the use of metal processing products demands higher standards for hygienic surfaces, corrosion resistance, mechanical strength, and ease of maintenance, primarily utilizing materials such as stainless steel. CTT typically employs common dies and fixtures to fabricate metal parts from very thin sheet metal, necessitating stringent tolerances and machining precision. CTT employs multiple processes to ensure product quality. From design development, blank processing, pre-bending processing, bending processing, welding processing, to surface treatments such as gold plating or painting, each step requires strict control. CTT offers a comprehensive suite of precision machining services, including high-precision laser cutting technology, CNC bending equipment, specialized die drawing techniques, and high-quality welding equipment. The company also enhances the aesthetic appeal and tactile quality of products through processes like wire drawing and polishing.

Request for a quote

CTT TECHNOLOGY (UK) LIMITED

United Kingdom

Material selection: The selection of high-quality AL6061-T651 aluminum alloy as raw materials, which has good processing properties and mechanical properties. Round rod processing: The aluminum alloy round rod material is placed on the lathe for processing, and through the lathe processing, it forms the desired shape and size. CNC four-axis machining: After the round rod machining, the aluminum alloy round rod is further machined using the CNC four-axis machining center to precisely control the size and shape. Smooth surface: The surface of the processed aluminum alloy round rod is smoothed to obtain a smooth and flat surface and improve the appearance quality. Anodizing: the natural anodizing treatment increases the corrosion resistance and surface hardness of the product, while maintaining the natural color of the aluminum alloy. Accuracy requirements: Ensure that the flatness of the product is within 0.

Request for a quoteResults for

Metal sheet - Import exportNumber of results

22 ProductsCompany type

Category

- Industrial sheet metal work (8)

- Rolled sheets - non-ferrous metal (3)

- Sheets and bands - non-ferrous metal (3)

- Profiled sheets - ferrous metal (2)

- Sheet Metal & Tubes (2)

- Boarding, metal (2)

- Sheet metals - stamping (1)

- Steels and metals - forming and cutting (1)

- Finished Metal Products (1)

- Roofing, solar protection (1)

- Corrugated sheets - non-ferrous metal (1)

- Furniture for kitchens (1)