- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- sheet metal

Results for

Sheet metal - Import export

ALPHA MANUFACTURING

United Kingdom

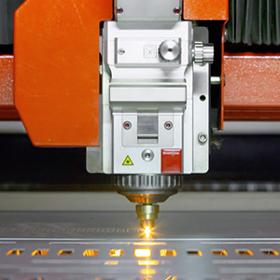

Utilising the latest in Fibre Laser Cutting technology Alpha Manufacturing are able to offer a versatile laser cutting service in various material types including; Mild Steel, Coated Steels, Stainless Steel, Aluminium, Wood and Plastics. We currently operate one Co2 Bystronic Laser, one Bystronic BySprintFiber 4020 machine and our latest addition to our Laser service, the Trumpf Trulaser 3030 fibre machine. Fibre optic laser is the latest technology in laser cutting, with complete accuracy and ultra high-speed cutting (whilst also using fewer power resources than traditional lasers, meaning reduced costs to the customer).

Request for a quote

DEKS INDUSTRIES EUROPE

United Kingdom

DEKS FastFlash Solar Flashing, a flexible flashing for the bottom edge of in roof solar installations. Its a fully adhesive butyl backed flexible flashing used for sealing the bottom edge of in roof solar installations, creating a wind and water tight solution which is easier to apply than many of the OEM solutions. The product stretch enables it to seamless follow the contours of the roof. Available in black, light grey & dark grey in various widths.

Request for a quote

ALPHA MANUFACTURING

United Kingdom

Our latest machine is the VTC-300 CII which is a highly versatile vertical machining centre with a large 2000 mm table cross dimension and high-speed rapid traverse of up to 36 m/min. Productivity and efficiency are greatly improved as the machine work envelope is separated into 2 work areas. This allows the machine to be in cycle, in one work area, while a part is being set up in the other work area.

Request for a quote

ALPHA MANUFACTURING

United Kingdom

Alpha offer a range of folding solutions depending on the needs of our customers including manual, automated and robot folding machines. Our manual folding line consists of 6 manned Amada press brakes capable of folding mild steel, coated steels, stainless steel, aluminium and alloys upto 4100mm in length. Automated folding offers optimised machine cycle times through automated tool selection and simultaneous component load and unload. Parts are programmed offline allowing the machine to run components whilst the next is programmed ready for production. We currently operate an automated TBZ panel folding line as well as completely automated robot folder.

Request for a quote

ALPHA MANUFACTURING

United Kingdom

Our plant is fully automated and employs industry leading pre-treatment process OXSILAN®. OXSILAN® is a new metal pre-treatment technology that is free from hazardous chemicals and provides superior corrosion resistance for a wide range of metal substrates. OXSILAN® replaces traditional iron and zinc phosphate products. The products provide a superior ecological profile. OXSILAN® is suitable for metal surface treatment, e.g. cold rolled steel, aluminium, zinc coated steels, as well as multi-metal applications.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ALPHA MANUFACTURING

United Kingdom

With a versatile punch/ laser combination service, Alpha are able to offer complete flexibility to produce punch details such as louvres and ribs alongside complex lasered profiles and etches in one process. The benefits of Punch/ Laser combination are that production time is dramatically reduced by combining the two processes. Costs savings are also made as complex and costly tooling is not required.

Request for a quote

ALPHA MANUFACTURING

United Kingdom

Alpha Manufacturing utilise the latest Pullmax and Trumpf punching machinery to offer unbeatable productivity, reliability and flexibility as well as ultimate efficiency through automated “lights out” production. We are able to perform 24-hour operation of unmanned CNC Punching machines which gives us greatly improved productivity with considerable quality improvements. Customers benefit from outstanding process consistency, offering industry leading punching standards.

Request for a quote

ALPHA MANUFACTURING

United Kingdom

Alpha Manufacturing have an experienced design team who are dedicated to working closely with our customers to ensure that every part we manufacture is exactly to clients' requirements. Using the CAD software and design techniques, our NPI (New product introduction) department ensure that all parts are manufactured in the most efficient and cost effective way, without compromising on quality through the manufacturing process.

Request for a quote

BIRMINGHAM SPECIALITIES LIMITED

United Kingdom

For many years now we have delivered unrivalled presswork and metal forming capabilities, and from our Birmingham based headquarters we continue to supply the quality and precision that you and other professionals servicing customers in other market sectors need to a high specification and at the most competitive price point.

Request for a quote

CTT TECHNOLOGY (UK) LIMITED

United Kingdom

Material selection: The selection of high-quality AL6061-T651 aluminum alloy as raw materials, which has good processing properties and mechanical properties. Round rod processing: The aluminum alloy round rod material is placed on the lathe for processing, and through the lathe processing, it forms the desired shape and size. CNC four-axis machining: After the round rod machining, the aluminum alloy round rod is further machined using the CNC four-axis machining center to precisely control the size and shape. Smooth surface: The surface of the processed aluminum alloy round rod is smoothed to obtain a smooth and flat surface and improve the appearance quality. Anodizing: the natural anodizing treatment increases the corrosion resistance and surface hardness of the product, while maintaining the natural color of the aluminum alloy. Accuracy requirements: Ensure that the flatness of the product is within 0.

Request for a quote

CTT TECHNOLOGY (UK) LIMITED

United Kingdom

In the medical field, the use of metal processing products demands higher standards for hygienic surfaces, corrosion resistance, mechanical strength, and ease of maintenance, primarily utilizing materials such as stainless steel. CTT typically employs common dies and fixtures to fabricate metal parts from very thin sheet metal, necessitating stringent tolerances and machining precision. CTT employs multiple processes to ensure product quality. From design development, blank processing, pre-bending processing, bending processing, welding processing, to surface treatments such as gold plating or painting, each step requires strict control. CTT offers a comprehensive suite of precision machining services, including high-precision laser cutting technology, CNC bending equipment, specialized die drawing techniques, and high-quality welding equipment. The company also enhances the aesthetic appeal and tactile quality of products through processes like wire drawing and polishing.

Request for a quoteResults for

Sheet metal - Import exportNumber of results

12 ProductsCompany type