- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- printer

Results for

Printer - Import export

M.R. MACHINE KNIVES LTD.

United Kingdom

We are able to supply a variety of thermal print heads, whether it is a “flat head”, “corner head” or “near edge” our team have the knowledge to work alongside our customers to help them find the correct part for their machine. Our main focus is to provide competitive pricing, quick lead times and a focus for maintaining the highest quality for our customers. Below are a few examples of products we stock and supply, please contact us and we will try our best to help find and supply you with the print head you require.

Request for a quote

GUANGDONG PINLONG PRECISION TECHNOLOGY CO., LTD.

United Kingdom

1.Fully Computerized 2.Roller Transfer; 3.High Speed, max speed up to 430 pcs/min. 4. CE quality standard. 5.Ink circulation system, auto self-wash device with monitor which can alarm when ink shortage, reduce paper waste. 6.Remote diagnosis function; 7.Slotter with PinLong patent design ensure boxes forming effect. 8.Die cutter with speed compensation.

Request for a quote

GUANGDONG PINLONG PRECISION TECHNOLOGY CO., LTD.

United Kingdom

Water based ink, without printing plate, Different brand of inkjet heads for optional, Suitable for bulk orders of corrugated carton box, Widely used in corrugated board & coated board & plastic hollow board. Perfect match with traditional flexo printer slotter die cutter machinery

Request for a quote

GUANGDONG PINLONG PRECISION TECHNOLOGY CO., LTD.

United Kingdom

1. Vacuum transfer, staggered vacuum transfer wheels and structure which ensures boards transfer smoothly. 2. Multi-sections vacuum volume control, automatic adjusting according to different boards size. 3. Automatic locking & position location, for printing plate. 4. Precise integral anilox roller & rubber roller/chamber blade system rise and fall structure, ensures perfect ink transfer and avoid shake when printing. 5. Registration with servo motor, lateral ball screw rod adjusting. 6. Rubber roller & anilox roller fast changing design. Chamber doctor blades and rubber roller are available, optional. 7. Anilox roller automatic self-wash device, much more convenient for circulation washing. 8. Automatic back to “zero” after washing printing studio. 9. Double diaphragm pump, and automatically ink recycling system, can reduce ink waste, and make ink recycling faster. Printing unit can equipped with hot air/IR dryer system.

Request for a quote

GUANGDONG PINLONG PRECISION TECHNOLOGY CO., LTD.

United Kingdom

Casemaker for corrugated industry, Suitable for corrugated carton box & packaging production, Fully computerized, Inline and offline operation method for optional, Folder gluer can equip with Valco Melton gluing system, Newest smart system of the whole line can assist the client monitor the machine production situation anytime. Main configuration included : 1. Feeder, Roller transfer controlled by Gearbox, Vacuum transfer controlled by servo motor; 2.Printer, Vacuum Transfer, Ceramic roller & Rubber roller for standard, Chamber doctor blade for optional; 3.Slotter, 8 Axis with PinLong patent design ensure the container forming effect. 4.Die Cutter with speed compensation. 5.Independent computer desk can operate the whole machine.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

AUTOMATED PACKAGING SYSTEMS

United Kingdom

The Autobag® PS 125 OneStep™ bagging machine is the ultimate in hand load packaging systems. This Print-n-Pack unit can efficiently print high resolution text, graphics and barcodes directly onto bags and present them for loading, bringing simplicity, versatility and value to low- to hand load applications. This compact bagging machine is ideal for mail order applications, short production runs and build-on-demand operations, offering bag sizes from 50 x 100 mm to 265 x 420 mm. The PS 125 OneStep bagging machine has a built-in PH 412 printer, eliminating the need for a separate labelling operation. The printer features a tilt-back print head for easy maintenance and the optional AutoLabel™ design software simplifies label creation. Pairing this bagging machine with system-matched Autobag polythene bags offers the ultimate solution for hand load applications. ** Click for more **

ADVANCED LABELLING SYSTEMS LTD

United Kingdom

Industrial labelling software with 100's of built-in printer drivers to get the most out of your label printer, coder and print & apply labelling equipment. Mix and match label formats between different models and even different makes! Create GS1 barcodes easily and in the knowledge they will be compliant. Standard formats for food, shipping labels, pallets and hazchem drums. Scale up from a benchtop printer to print and apply with ease. Share data across networks and the cloud. Keep formats locked-down and secure with password protection. NiceLabel is the industry standard label design and print management software. Easy to start and very scalable, to include a graphical application builder that allows you to create a custom user interface and integrate data from other applications for printing as text or barcodes on your labels without writing a single line of code. Choose to run on-premise or in the cloud. A huge selection of printer drivers available.

Request for a quote

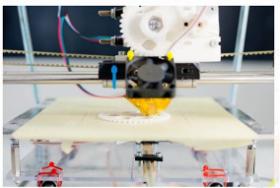

MITCHELL AND SON 3D PRINTING SERVICE

United Kingdom

3D printing or additive manufacturing is a process of making three dimensional solid objects from a digital file. The creation of a 3D printed object is achieved using additive processes. Mitchell and Son 3D Printing Service provides a totally bespoke 3D Printing Service for all sectors using a range of materials. Additive manufacturing uses data computer-aided-design (CAD) software or 3D object scanners to direct hardware to deposit material, layer upon layer, in precise geometric shapes. . It is defined as the process of joining materials to make objects from 3D model data, usually layer upon layer. Benefits of additive manufacturing (3D Printing Below are four major advantages that additive manufacturing can provide to help companies reduce cost, timing, and risk. ... 4 Major Advantages of Additive Manufacturing Reduced Tooling Costs. ... Quicker Speed to Market. ... Easily Test Complex Component Geometries. ... Better Component Quality.

Request for a quote

MITCHELL AND SON 3D PRINTING SERVICE

United Kingdom

We Provide a full rage of Business Printing from Prototypes, to Promotional Printing and Sales and installation of office and 3D Printing Equipment Bespoke 3D Printing Service: The Core of what we do is providing a bespoke 3D Printing Service. Why 3D Print? Speed to Market, Cost Saving, reduced Waste, Recycled Plastic .. Did you know the most common 3D Printed Material, PLA is a by product of corn and is Biodegradable? CAD ( Computer aided design): The internet is a wash with 3D Models and CAD models of most things these days, but when a customer has a specific need and requires a bespoke item, we offer a full CAD service with willingness to sign an NDA if required

Request for a quote

CTT TECHNOLOGY (UK) LIMITED

United Kingdom

Die blanking is the initial step of the industrial inkjet printing machine, which uses a professional mold to precisely cut the raw material into the desired component shape, the mold molding process is through the precise mold and pressure action, laser welding is an efficient and accurate welding method for the inkjet machine components firmly connected together. The rivet or riveted piece is firmly pressed into the material by pressure, increasing the strength of the connection between the parts. The welding method enables precise connection between components while ensuring the strength and stability of the connection. Through the drawing and polishing operation, the rough and uneven parts of the surface are removed, and the dirt can be peeled off from the surface of the parts through the vibration effect of ultrasonic waves, ensuring the cleanliness and hygiene standards of the printer.

Request for a quoteResults for

Printer - Import exportNumber of results

11 ProductsCountries

Company type

Category

- Cardboard and cardboard products - processing machinery (4)

- 3D printers (1)

- Labelling machines (1)

- Packing and packaging - machinery and equipment (1)

- Advertising design - graphic artists and designers (1)

- Lithographic printing (1)

- Prototypes, industrial (1)

- Software for industry (1)

- Stainless steels (1)

- Thermoforming, plastics - machinery (1)