- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- precision cutting

Results for

Precision cutting - Import export

DAVALL GEARS LTD.

United Kingdom

Davall manufacture spiroid gearing, Spiradrive. A high torque low backlash gear system

Request for a quote

ALPHA MANUFACTURING

United Kingdom

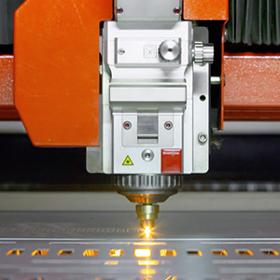

Utilising the latest in Fibre Laser Cutting technology Alpha Manufacturing are able to offer a versatile laser cutting service in various material types including; Mild Steel, Coated Steels, Stainless Steel, Aluminium, Wood and Plastics. We currently operate one Co2 Bystronic Laser, one Bystronic BySprintFiber 4020 machine and our latest addition to our Laser service, the Trumpf Trulaser 3030 fibre machine. Fibre optic laser is the latest technology in laser cutting, with complete accuracy and ultra high-speed cutting (whilst also using fewer power resources than traditional lasers, meaning reduced costs to the customer).

Request for a quote

CTT TECHNOLOGY (UK) LIMITED

United Kingdom

Die blanking is the initial step of the industrial inkjet printing machine, which uses a professional mold to precisely cut the raw material into the desired component shape, the mold molding process is through the precise mold and pressure action, laser welding is an efficient and accurate welding method for the inkjet machine components firmly connected together. The rivet or riveted piece is firmly pressed into the material by pressure, increasing the strength of the connection between the parts. The welding method enables precise connection between components while ensuring the strength and stability of the connection. Through the drawing and polishing operation, the rough and uneven parts of the surface are removed, and the dirt can be peeled off from the surface of the parts through the vibration effect of ultrasonic waves, ensuring the cleanliness and hygiene standards of the printer.

Request for a quote

CTT TECHNOLOGY (UK) LIMITED

United Kingdom

CTT has demonstrated outstanding expertise and an innovative spirit in the field of new energy vehicle chassis manufacturing. The company employs a range of advanced machining processes, from precision cutting and CNC bending to automated welding technology. Each step ensures high-performance and high-quality products. Additionally, professional surface treatment and precision machining of the chassis components further enhance the durability and reliability of the products. In terms of quality control, CTT has implemented a rigorous inspection process to ensure that every product meets high standards. After accurate assembly and comprehensive performance testing, CTT provides strong support for the chassis manufacturing of new energy vehicles, winning widespread trust and recognition from customers.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Precision cutting - Import exportNumber of results

4 ProductsCompany type