- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- mechanical engineering

Results for

Mechanical engineering - Import export

RUSSELL FINEX LTD

United Kingdom

Ultrasonic sifter prevents blinding and blocking when screening difficult powders. For more details, please send us a message or click on the website link.

Request for a quote

LUBCON LUBRICANTS UK LTD

United Kingdom

Noise-tested, ester-based special greases with polyurea for long-term and long-life lubrication in mechanical engineering.

Request for a quote

LUBCON LUBRICANTS UK LTD

United Kingdom

Premium high-temperature oils. Fully synthetic lubricants formulated with PAO/ester oils and special additives for extreme operating conditions in temperatures up to approx. 250 °C, non-toxic and miscible with mineral oils. Recommended for the lubrication of double belt presses, film stretching machines, timing and conveyor chains, slide rails in lacquer drying furnaces in the automotive sector or the mechanical engineering sector as well as bearings and gears at medium loads and extremely high temperatures.

Request for a quote

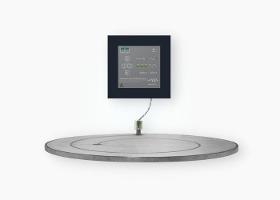

BLUE CHIP TECHNOLOGY LTD

United Kingdom

If your embedded system requires a custom enclosure, you may anticipate having to approach an industrial design house and commission the enclosure design as a separate project. This adds cost and can increase the risks as you may face communication difficulties and hold-ups between suppliers. With Blue Chip Technology’s in-house mechanical design engineering capabilities, you have the option of keeping all aspects of your project with just the one partner. With over 30 years of mechanical design experience and the advantage of being co-located with the electronics design and manufacturing teams, our mechanical design engineers are best suited to take care of your enclosure design. We use the Creo Parametric 3D CAD system (formerly Pro Engineer) which can seamlessly integrate with CAD models authored in other systems, so if you already have an existing design or concept we can build a solution from that.

Request for a quote

JME LTD

United Kingdom

JME Advanced Inspection Systems has a reputation as the market leader for the design and manufacture of high quality inspection systems, this includes our range of Pipeline Crawlers used by the ‘Non-Destructive Testing’ industry. For over 30 years, JME Pipelines Crawlers have been continually improved and updated to produce panoramic radiographs of the highest quality. Our range of systems are designed to inspect circumferential butt welds in new pipelines, such as oil and gas transmission pipelines, from 6” to 72” (15.24cm to 183cm). As a self-contained and self-powered exposure vehicle, they are ideal for a vast range of NDT applications both on and off shore. Over the past 30 years, JME has built its reputation on innovation, quality, service, and commitment to our clients. As a company, JME thrives on customer satisfaction, which is why many of our customers have been using our services for nearly 30 years.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Mechanical engineering - Import exportNumber of results

5 ProductsCompany type