- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- design engineer

Results for

Design engineer - Import export

TITAN MACHINERY

United Kingdom

Hydraulic station manufacturing refers to the process of designing, assembling, and producing hydraulic power units or stations. These units are essential components of hydraulic systems used in various industrial applications, including manufacturing, construction, agriculture, and more. Hydraulic stations provide the necessary power and pressure to drive hydraulic machinery, such as cylinders, motors, and valves. The manufacturing process of hydraulic stations involves several key steps: Design and Engineering: The process begins with the design and engineering of the hydraulic station. This includes specifying the required flow rate, pressure, and functionality based on the application's needs. Engineers create detailed schematics and plans for the hydraulic station. Component Selection: Manufacturers carefully select hydraulic components such as pumps, motors, reservoirs, valves, filters, and hoses based on the system's specifications. The chosen components should be durable.

Request for a quote

OMNITRACK

United Kingdom

Our Medium Duty ball transfer units are machined from solid steel bar which is heat-treated to provide a hemispherical wear-resistant chamber within which the recirculating balls can support the protruding, load-bearing main ball. This robust, low-noise design is engineered for applications requiring conventional (ball ‘up’) orientation. Additional options for this range include impact-absorbing top cap options, and additional drain channels where required, making these transfer units the air cargo industry standard.

Request for a quote

NO GREY AREA

United Kingdom

With an installation history among NGA’s team dating back to the 1980’s, along with our in-house design, engineering and LED teams, NGA provide an unrivalled stretch ceilings experience. Stretch fabrics have a vertically endless array of options available including acoustically treated, satin, matte, translucent, lacquer suede and even printed. The versatillity of our product allows each client to achieve a very unique project, whilst maintaining a high quality finish, as well as a European fire certification, and a low maintenance finish. With industry leading experience, 20 years warranties and roll widths of up to 5.5 without a seam, No Grey Area can handle any stretch fabric requirements.

Request for a quote

NO GREY AREA

United Kingdom

NGA’s Ring pendant light is an ideal choice for the designer who doesn’t want to be limited in diameter, width, output or lighting colour temperature. Our pendant lighting range has been designed and engineered in the UK where we believe we have achieved the perfect fusion between lighting and functionality. With a multitude of profiles available we have diffuser options that include acrylic, silicone and stretch fabric for a perfectly seamless finish. Paired with a range of application based Bluetooth or WIFI enabled control solutions for dynamic of colour change effects, our Halo pendants are at the forefront of lighting with user friendly, smart technology.

Request for a quote

DRALLIM INDUSTRIES LIMITED

United Kingdom

Our skilled staff specialise in solving the sort of engineering and manufacturing conundrums you’d rather do without. Our organisation is geared to producing one-off prototypes and small batch manufacturing; We take pride in overseeing the entire process, from design, prototyping and manufacture to delivery, installation, full product certification and after-sales service. With experience in providing comprehensive turnkey assembly test solutions covering electronic, electromechanical, engineering and mechanical products we offer our customers a total contract manufacturing service. When an order is received, a project plan is then developed; our team uses detailed documentation, engineering change and reporting control to ensure continued information integrity. An experienced project manager acts as the interface between Drallim and our customers although, at the same time, we actively encourage engineer-to-engineer communication.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

GIDROLAST CO., LTD

United Kingdom

Military and Naval equipment has some of the most demanding specifications and requirements of any machinery. It has to. Lives depend on it. From the frozen arctic tundra to hot humid jungles, from arid sand-blown deserts to the windswept salt spray of the oceans, military equipment is exposed to every conceivable environment on the planet. Military hardware is often stored unused for months or years at a time, but then must be ready to move and operate at a moment’s notice. The hydraulic cylinders used in this equipment must be of the very best quality. Gidrolast makes them. Gidrolast cylinders are carefully designed and engineered, using only the finest construction materials, and are precision-manufactured with cutting edge industrial equipment. The result is cylinders that meet the toughest military and naval specifications.

Request for a quote

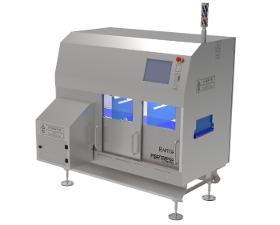

FORTRESS TECHNOLOGY (EUROPE) LTD

United Kingdom

The Raptor is employed to inspect for contaminants in each product and reject contaminated packs. The system has been designed, engineered and constructed to the highest care/food grade engineering standards. It is capable of processing packaged products up to 6kg and 300mm x 400mm in size.

Request for a quote

FORTRESS TECHNOLOGY (EUROPE) LTD

United Kingdom

The Raptor is employed to verify the weight and inspect for metal contaminants of each product and reject non-conforming packs. The system has been designed, engineered and constructed to the highest care/food grade engineering standards. It is capable of processing packaged products up to 6 kg.

Request for a quote

LSJ ENGINEERING LTD

United Kingdom

LSJ Engineering designs and provides structural steel for commercial buildings across Essex, London, the South East of England and beyond. We survey, design and advise on all aspects of access requirements. We help satisfy building and fire regulations to ensure full compliance. Our work is CE certifiable. Browse our previous structural steel projects on our website and get in touch if you have a project we can help with!

Request for a quote

INTEGRATEDAIR SYSTEMS

United Kingdom

Many types of materials generate varying types of dust, dependent on the processes and materials used in the production environment. Some of these dusts can be hazardous and potentially explosive – to keep your work space safe and healthy, careful consideration and planning should be applied when considering dust removal systems. Make integratedAIR Systems your trusted dust control partner and we will do the rest. With experience in multiple industries, such as commercial print, corrugated card, beverage cans and many more, we are dedicated to our trade and ready to work with you. Working closely with HSG258 guidance our Design Engineers can make sure that your systems are compliant with whatever regulations that need to be followed depending on the type of dust or fume that needs to be extracted.integratedAIR System ensure our systems are in line with the Dangerous Substances and Explosive Atmosphere Regulations (DSEAR) alongside the ATEX Directive.

Request for a quote

THERSER (UK) LTD

United Kingdom

At Therser we design and manufacture high-quality industrial kilns of different types to suit the needs of different manufacturing businesses. Our design engineers work with you to create a bespoke kiln that precisely allows you to meet your business goals. This is based on an understanding of your products, your industry, your production targets and firing volumes.

Request for a quoteResults for

Design engineer - Import exportNumber of results

12 ProductsCountries

Company type

Category

- Computer engineering (1)

- Weighing and dosing equipment (1)

- Ceilings, suspended (1)

- Ceramic and enamel kilns (1)

- Cylinders, pneumatic (1)

- Dust extraction installations and equipment (1)

- Food Industry - Machines & Equipment (1)

- Hydraulic equipment (1)

- Light fixtures, decorative (1)

- Nuclear power stations - installations and equipment (1)

- Steel, structural (1)

- Wheels, castors and rollers - metal (1)