- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- coding

Results for

Coding - Import export

VALDAMARK LIMITED

United Kingdom

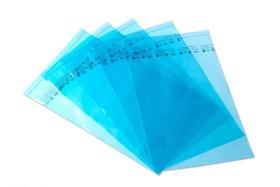

housing the Right Anti-Static Packaging: zip Lock TopShield® vs.Standard Bags. Valdamarkdirect offers two anti-static packaging solutions to safeguard your electronics from static electricity damage: zip Lock TopShield® and standard anti-static bags.Both utilise conductive materials to shield components, but cater to different needs. zip Lock TopShield®: Premium Protection This top-of-the-line option boasts exceptional static and electromagnetic interference (EMI) shielding.Its high-performance, conductive polymer material excels in blocking electric fields and dissipating static charges, offering superior protection for sensitive electronic components, medical devices, and mission-critical equipment.Additionally, the resealable ziplock closure allows for easy access and repeated use, making it ideal for long-term storage or frequently accessed items.

Request for a quote

VALDAMARK LIMITED

United Kingdom

Protect metal parts from corrosion with Large Cortec VpCI® 126 zip Lock Bags. These bags use patented VpCI® technology to create an invisible, self-replenishing protective layer. Ideal for bulky items, they offer superior, multi-metal corrosion protection in dry or humid conditions. No residue, easy to use, and reusable. Made from durable polyethylene with a resealable zipper. Protects against oxidation, rust, and tarnish. Perfect for automotive, aerospace, hydraulic, electrical, military, and industrial components. Eco-friendly and recyclable. Ensure long-term preservation of your valuable metal assets.

Request for a quote

VALDAMARK LIMITED

United Kingdom

Protect metal parts from corrosion with Daubert Cromwell Premium MetalGuard® VCI zip Lock Bags. These bags use VpCI® technology to create an invisible, protective layer against rust, tarnish, and corrosion. The robust polyethylene film is infused with VpCI® that vaporises and coats all metal surfaces, neutralising corrosion. Unlike other methods, VpCI® protects even hard-to-reach areas. Transparent film allows easy inspection, while the resealable zipper maintains protection. Available in various sizes for different parts, these bags are environmentally friendly and easy to use. Ideal for automotive, aerospace, oil and gas, manufacturing, electronics, and construction industries. Safeguard your valuable metal components with this superior corrosion prevention solution

Request for a quote

VALDAMARK LIMITED

United Kingdom

Cortec VpCI® 126 Vapor Phase Corrosion Inhibitor zip Lock Bags offer superior protection for metal components during storage and shipping. Utilising innovative VpCI technology, these bags create a corrosion-inhibiting environment by releasing vapor that forms a molecular shield on all metal surfaces.This invisible layer safeguards against rust, tarnish, and other corrosion forms without affecting part appearance or properties. Designed for versatility, these bags protect a wide range of metals, including steel, aluminium, and copper.Their ziplock closure ensures easy use and eliminates the need for harmful chemicals.Offering up to 24 months of protection, these bags excel in harsh conditions. Environmentally friendly and recyclable, they provide a clean, effective solution. The transparent material allows for easy inspection, while various sizes accommodate different components.

Request for a quote

VALDAMARK LIMITED

United Kingdom

Medium size Cortec VpCI® 126 VpCI zip Lock Bags. Protect your metal assets with Cortec VpCI® 126 zip Lock Bags. These innovative bags use Vapor Phase Corrosion Inhibitor (VpCI) technology to create an invisible, protective layer on metal surfaces, preventing rust, tarnish, and corrosion. Ideal for electronics, machinery, automotive parts, and more. Easy-to-use, resealable, and environmentally friendly. Safeguard your valuable equipment with this effective corrosion solution.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

SUNALA LIMITED (TRAVTEC GROUP)

United Kingdom

for use with CIJ & laser printers for coding on underside of cans, jars, tubs & bottles whilst passing along a conveyor.

Request for a quote

SUNALA LIMITED (TRAVTEC GROUP)

United Kingdom

The Travtec range of conveyor accessories has been increasing the efficiency of product manufacturing for over 25 years. Whether you want to code on the underside of aerosol or beverage cans, cosmetic jars and bottles our Diverter and Paratran are designed to operate with your CIJ printer or laser to provide a clean, readable code at any line speed. Our Mini-press, presses the lids & caps onto bottles & jars after hand or mechanical application, preventing wrist strain and other potential injuries. To compliment the machine, our Caplicator can apply the caps & lids before pressing them onto the container. For Tamper-Evident sealing, Our Tiny Tampino Tabletop label applicator is widely used around the world for product security. Our Labelino range of label applicators are used for applying print &self adesive labels to flat & round containers. For labelling or printing corrugated cases the Travtec TR-1000 Casefeeder feeds flat corrugated cases vertically to give 4 side access

Request for a quote

KEYTRACKER LTD

United Kingdom

10 push-button electronic code.

Request for a quote

WORCESTER ENGINEERING

United Kingdom

We offer ZURICH certified Coded Welding Services as follows BS EN ISO 9606-1 : 2017 BS EN ISO 15614-1 : 2017 LEVEL 2 Our approval codings cover a wide range of applications within our target industries. We encourage enquiries for 'assembly & weld' opportunities. Our hygienic workshops offer a clean and efficient environment for multiple batch / jig work. We're happy to quote full job or just labour, free issue material. We have storage facilities and happy to discuss call off. We are happy to certify our workforce to any coding required to undertake customer requirements. Our coded welding staff are also placeable, providing cover for holidays, illness and staff shortages at your premises.

CTT TECHNOLOGY (UK) LIMITED

United Kingdom

Die blanking is the initial step of the industrial inkjet printing machine, which uses a professional mold to precisely cut the raw material into the desired component shape, the mold molding process is through the precise mold and pressure action, laser welding is an efficient and accurate welding method for the inkjet machine components firmly connected together. The rivet or riveted piece is firmly pressed into the material by pressure, increasing the strength of the connection between the parts. The welding method enables precise connection between components while ensuring the strength and stability of the connection. Through the drawing and polishing operation, the rough and uneven parts of the surface are removed, and the dirt can be peeled off from the surface of the parts through the vibration effect of ultrasonic waves, ensuring the cleanliness and hygiene standards of the printer.

Request for a quoteResults for

Coding - Import exportNumber of results

11 ProductsCompany type