- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- filling equipment

Results for

Filling equipment - Import export

STAR UNIVERSAL (GOSPORT) LTD

United Kingdom

The Star 96 is available as a bench mounted or free-standing bag sealer, designed for sealing bags when the product can be laid down. The Star 96 is the industry standard, sealing a whole host of products ranging from pet bedding to pharmaceutical supplies. The Star 96 is solenoid operated as standard, with foot switch operation. The solenoids close the jaws and keep them closed for the duration of the weld and cool cycle, allowing the operator to prepare the next bag. If the machine is being used quickly, the Star MkVI timer board can be set to compensate the heat built up. A variety of product support tables and machines are available on request. Constant heat machines are available for special bag materials such as paper bags. For the sealing of medical and pharmaceutical products, the Star ARTICS controller can be specified to give unparalleled seal quality and consistency.

Request for a quote

STAR UNIVERSAL (GOSPORT) LTD

United Kingdom

The Star HM range are bag sealers designed for lighter gauges of materials. The impulse sealers are capable of sealing up to 250 µm (1000g). There is also a constant heat machine for laminates and complex materials. Both hand and foot operated machines are finished in painted mild steel. A stainless steel food shop counter top bag sealer and tube sealer are also available. The robust construction allows for years of service with a full spares and service back up. Removable sealing bars allow for ease of maintenance and replacement of consumable items.

Request for a quote

STAR UNIVERSAL (GOSPORT) LTD

United Kingdom

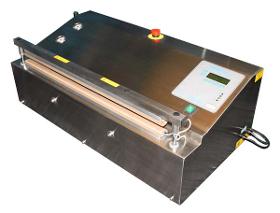

The Star Vacuum Chamber Sealer The Star vacuum chamber range is used for vacuum sealing products where a high vacuum level is required. The product is placed in an unsealed bag inside the chamber. When the lid is closed the built in vacuum pump evacuates the chamber and seals the bag whilst in a vacuum. On completion of the sealing cycle atmospheric pressure is let back into the chamber and the lid opens automatically. Typical applications include food and electronics packing but special versions have been built for the chemical and medical sectors. Bench top and free standing machines Stainless steel finish Single or multiple sealing bars, single and double heat Gas flushing with multiple cycles available Single program and multiple program versions allowing different vacuum and weld parameters to be preset The chamber lid is released on completion of the cycle

Request for a quote

STAR UNIVERSAL (GOSPORT) LTD

United Kingdom

The Star 56 range of bag sealers consists of a power pack and a set of sealing jaws designed for heat sealing products in situ or for a bag sealer to be incorporated into a parent machine. The range of sealing heads is ideal for uses such as sealing valve sacks, foil or plastic machinery covers and sealing straps onto bulk bags. We also produce a range for sealing dangerous/ toxic products where the seal incorporates a cut so no product can escape. Seal cycle initiation can be via foot switch, push button or automatic (when the jaws are closed). The power pack is connected to the jaws by a lead, allowing the jaws to be used in awkward positions. Adjustable weld and cool timers control the sealing cycle, allowing them to be used on most materials. The indicator lights on the power pack or sealing jaws advise the operator when the weld and cool cycle are complete. Special sealing heads producing shaped welds can be made for almost any application.

Request for a quote

STAR UNIVERSAL (GOSPORT) LTD

United Kingdom

The Star Platen Sealer is available either bench-mounted or free-standing, producing shaped or multiple welds. The Star Platen Sealer can be manually or pneumatically operated with either foot switch or push button operation. The Star Platen Sealer can seal most modern plastic, biodegradable, foil, paper and laminate packaging materials and is constructed from anodised aluminium profile to give rigidity whilst keeping the weight down. The Star Platen Sealer is available with: A variety of seal shapes, sizes and widths Multiple seals can be produced at the same time Automatic cutter for a straight or shaped cut out A variety of jaw openings dependant on application Interchangeable sealing heads for different welds from the same machine Either one or both jaws heated A range of control options are available including the ARTICS and MkVI C controllers

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

STAR UNIVERSAL (GOSPORT) LTD

United Kingdom

The Star 106 range of vacuum sealing machines are available in a bench mounted of free-standing format. A probe extends into the bag and evacuates the air without the need to place the product inside a vacuum chamber, so there is no limit to the maximum product length. Although predominantly used for sealing food products and electronics, special purpose machines have also been produced for the chemical and agricultural sectors. Seal lengths from 500mm to 900mm. Vacuum pumps from 3cmh to 15cmh. 230V or 115V power supply. An optional gas flush facility is available to allow the product to be packed in an inert atmosphere. Weld and cool cycle times are adjustable. Seal width 6mm as standard, other options including double welds available. With both jaws heated, most modern barrier materials such as foils and nylon laminates can be sealed. A range of control options are available including the Star ARTICS and MkVI C controllers

Request for a quote

STAR UNIVERSAL (GOSPORT) LTD

United Kingdom

The Star Medical sealers have been developed for applications where ease of cleaning is critical, such as in the food, medical and pharmaceutical industries. The machine body can be built in a number of different designs with the jaws operating vertically (when a product is best sealed laying down) or horizontally (when a product is best sealed standing up). With the cylinders moving the top jaw directly, jaw alignment and pressure are much more controllable. This machine design is available with all the Star controllers. The Star Medical Vacuum sealer allows for the air to be removed from a bag prior to sealing. The machine is available with a range of vacuum pumps or vacuum generators dependant on your application. Gas flushing is available for modified atmosphere packaging. This machine design is available with either our ARTICS or Medical controllers.

Request for a quote

STAR UNIVERSAL (GOSPORT) LTD

United Kingdom

The Star Medical sealers have been developed for applications where ease of cleaning is critical, such as in the food, medical and pharmaceutical industries. The machine body can be built in a number of different designs with the jaws operating vertically (when a product is best sealed laying down) or horizontally (when a product is best sealed standing up). With the cylinders moving the top jaw directly, jaw alignment and pressure are much more controllable. This machine design is available with all the Star controllers. The Star Medical Vacuum sealer allows for the air to be removed from a bag prior to sealing. The machine is available with a range of vacuum pumps or vacuum generators dependant on your application. Gas flushing is available for modified atmosphere packaging. This machine design is available with either our ARTICS or Medical controllers.

Request for a quote

STAR UNIVERSAL (GOSPORT) LTD

United Kingdom

The Star 66 free-standing sealer is designed specifically for sealing bags where the product is best standing upright. Typically, this lends itself to the bagging of bulk product such as aggregates, prepared foods and chemicals. The Star 66 is available in a range of formats to suit the product, working environment and bag type. The rugged, powder coated mild steel body is built to withstand the rigours of hostile working environments, such as builders' yards or coal merchants. The foot switch initiated solenoid jaw operation allows the operator to be preparing the next bag whilst one is being sealed. An IP65 stainless steel machine is available for food environments. Constant heat jaws for heavy weight foil and multi-wall bags are also available. For applications where seal quality is paramount, such as hygroscopic compounds, the Star MkVI C or ARTICS controller should be specified.

Request for a quote

PETAINER

United Kingdom

Petainer Water Cooler Bottles are a refillable PET solution with market-leading durability. They are compatible with existing washing and filling equipment and can be reused up to 40 times, helping you achieve a high trip rate with a lower packaging cost per litre. - Reusable 40x: bottles reduce the cost of unit per trip and reduce packaging cost per litre - 60% lower carbon emissions than polycarbonate - 100% recyclable - Available in preform for enhanced logistics CO2 reduction - Brands moving away from polycarbonate to PET over medical fears of exposure to BPA - Better seal than with polycarbonate for fewer leaks during transport and handling - PET can survive drops of 2 m - Inbuilt scuff resistance - Crystal clear & keeps shine against UV - No capex: fit on existing filling & washing lines -Available in preform; (14.5x more per shipment) - Petainer global blow moulding partner support - Strength of seal and product leads to less product loss

Request for a quoteResults for

Filling equipment - Import exportNumber of results

11 ProductsCountries

Company type