- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- energy design

Results for

Energy design - Import export

THE FUME CUPBOARD COMPANY LTD

United Kingdom

The Airflow 8 Cupboard is best suited for Industrial and Commercial situations. These Ducted Fume Cupboards are available in standard widths of 1200mm, 1500mm, 1800mm and 2000mm. Compliant with: Building Bulletin 88 (Rev G9.) Designed and manufactured in accordance with Energy Efficient Design and Operation of Fume Cupboards Guide 320. Meets BREAMM Hea 17 and Ene 11 compliance. Please note a suitable extraction system will be required for the fume cupboard to operate correctly, the extract system should be designed and installed to meet the requirements of D.W. 154 and Building Bulletin 88. The Fume Cupboard Company can offer a full turnkey solution The Airflow 8 Fume Cupboard range include :- Standard Bench Mount Walk-in Double Fronted Double Fronted Walk-in Slim Profile Sides

Request for a quote

ALXR LIMITED

United Kingdom

Welcome to our range of high-quality surgical energy devices and equipment designed for medical professionals and hospitals. Our state-of-the-art diathermy generators, electrosurgery units, surgical generators, and RF generators provide precision and control during surgical procedures. Our electrosurgical generators, bipolar generators, and monopolar generators are built to meet the demands of modern surgical procedures. We offer a range of electrosurgical instruments and surgical equipment that ensure superior tissue coagulation and electrosurgical cutting. Our high-frequency surgical equipment and cautery units are perfect for operating room equipment and surgical energy device requirements. Whether you need to perform minimally invasive surgery or complex surgical procedures, our diathermy machines and equipment provide the power and precision required for success. Choose our medical generators and diathermy equipment for your surgical energy device requirements

Request for a quote

NETZSCH MASTERMIX

United Kingdom

Grinding and Dispersing down to the Nanometer Range The high-speed mill system Zeta® with improved peg grinding system optimizes your production capacity, energy demand and quality. Designed for circulation operation and multi-pass operation, you achieve high throughput rates and high quality with a narrow particle size distribution for higher viscous products. A minimal control expenditure is necessary to guarantee highest reproducibility and save additional costs. The large dimensioned rotor with slotted pipe separation enables the use of very small grinding media of different materials. Special grinding chamber designs of ceramic (NETZSCH-Ceram C, NETZSCH-Ceram N, NETZSCH-Ceram Z) and NElast are available for metal-free processing of your products. ** click to know more **

Request for a quote

VCSP LTD

United Kingdom

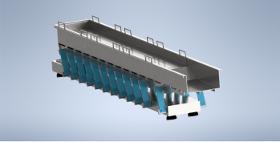

VCSP's vibratory conveyors represent the pinnacle of innovation in material handling. Designed for efficiency and precision, our conveyors are tailored to meet the unique challenges of various industries, from food processing to pharmaceuticals. At the heart of our design philosophy is the user's need for rapid, gentle, and accurate material transfer. Our conveyors ensure minimal product degradation, making them ideal for delicate items. The energy-efficient design reduces operational costs, while the modular build allows for easy customization and scalability. Crafted using food-grade materials, they prioritize hygiene, ensuring that products remain uncontaminated. Specialized surfaces further facilitate thorough sanitization, addressing allergen and cross-contamination concerns. With VCSP's vibratory conveyors, businesses not only benefit from increased production efficiency but also achieve compliance with stringent industry regulations.

Request for a quote

VCSP LTD

United Kingdom

VCSP's Vibratory Laning and screening Conveyors are the epitome of precision and efficiency. Expertly engineered, they ensure exact product laning and screening capabilities. By harnessing the power of vibration, these conveyors align products perfectly. Customizable to diverse needs, they fit various product types and capacities. Key features include adjustable vibration settings, a range of surface finishes, and energy-efficient designs. Built for durability, they promise longevity even in demanding industrial settings. Their user-friendly design ensures easy maintenance, while their adaptability allows for integration into existing production lines. Ideal for robotic pick and place, automated assembly, packaging lines, and quality control, VCSP's Vibratory Laning Conveyors are the answer to precise product handling and alignment

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ARCH.DESIGN

United Kingdom

Our Design 360 concept is a global solution created for office fit-out. Our goal is to create new working environment conducive to well-being and to a new energy vector. Our DESIGN 360 concept has 4 steps : THINK (audit, survey), CREATE (design, architecture, space-planning), DELIVER (site construction & management, furniture), SUPPORT (implementing and follow up). We are attached to carrying-out our customer's project weather in Paris or London, on time and within budgets. So each project has a project manager appointed that will be the customer's contact to prepare, design, construct and deliver the new office spaces.

COLLOIDE ENGINEERING SYSTEMS

United Kingdom

Colloide designs and builds customised energy centres which generate heat which can then be distributed to buildings or district heat networks. We can also incorporate CHP units within the energy centre, providing electricity along with heat and a low carbon heat and power solution. Our energy centres are often designed to have more than one energy source, allowing the plant operator to vary the energy sources in relation to the energy demand and the best value for money at a given time. The energy sources may include: Gas fired boilers. Biomass boilers. Heat pump. Oil fired boilers. Combined Heat and Power (CHP) unit Our centres are engineered to include the energy sources, thermal stores, instrumentation, control systems, pumping and pipework network – building in as much flexibility as possible so that the plant can be operated as efficiently as possible.

Request for a quote

COLLOIDE ENGINEERING SYSTEMS

United Kingdom

Colloide designs and installs heat pump systems. The heat pump extracts the energy at the source temperature and then raises the temperature to a useable level. A heat exchanger is used to extract the heat from the circuit at this point, with the now cooled medium being returned to the source where it is reheating. Reversible heat pumps can also be used in cooling function which can be important in the summer months. The heat pump works as part of a closed loop, operating between the heat source and the building where it is to be used. Heat sources include air, water, ground and waste heat. The higher the temperature and larger the size of the source energy, the better it is for providing energy. Colloide designs its systems to maximise the return from the heat source. Our heat pumps include a control system. The control system will vary depending on the plant, but is always designed to give our customers full control, including the ability to monitor performance remotely.

Request for a quote

COLLOIDE ENGINEERING SYSTEMS

United Kingdom

District heating systems include a centralised energy centre which then distributes the heat through a network of insulated pipes to the buildings which are connected to the network. The network of pipework consists of a flow and return loop which passes each building. Colloide uses local substations in each building to control the flow of water from the district heating pipework loop through each substation and this flow is used to generate heat in the local building. The central energy centres are generally designed to have more than one energy source, which allows the plant operator to select the most cost efficient and sustainable way of providing the energy needed with the energy sources being brought on and off line to meet demand. We design and build the district heating and cooling networks to include the pumps, pipework, thermal stores, instrumentation, control systems, local substations, heat exchangers and communication through a central control system.

Request for a quoteResults for

Energy design - Import exportNumber of results

10 ProductsCountries