- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- model making

Results for

Model making - Import export

1ST MACHINE TOOL ACCESSORIES

United Kingdom

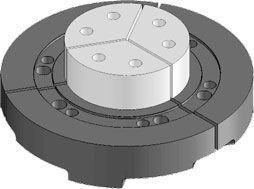

Reduce setup and changeover times by up to 80% Eliminate out of round conditions and concentricity problems Effectively double the holding capacity of any chuck without eliminating the ability to hold small parts Light-weight 6061 T-6 or 319 for weight saving DESCRIPTION Abbott‘s master plate and segment system is a great choice for turning larger diameter work pieces. The system consists of an aluminum master plate, similar to a thin Pie Jaw®, which is pre-drilled and keyed to accommodate Abbott’s standard, off-the-shelf segment rings. Plates are available in various diameters from 15 to 60 inches and can be mounted on 8-60 inch diameter chucks, effectively increasing the holding capability of smaller chucks. The master plate can be custom machined to fit any model chuck, making it a permanent universal fixture on any machine.When using this system, the transition from one job to the next simply requires bolting on a new size or configuration of segments before continuing

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

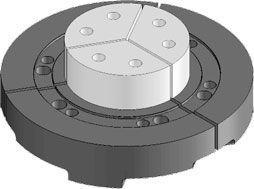

Universal quick change system for any chuck Repeatability < 0.001" TIR Reduce setup and changeover times by up to 80% Eliminate out of round conditions and concentricity problems DESCRIPTION When it comes to turning/holding smaller diameter parts Abbott’s precision master plate and segment system is an ideal choice for high changeover and short running jobs. Due to the system’s high repeatability, it is an excellent alternative to more expensive quick change chucks. The system consists of an aluminum master plate, similar to a thin Pie Jaw®, which is bored and bushed to accommodate Abbott’s standard, off-the-shelf pinned segments. Plates are available in 8, 10 and 12 inch diameters and can be mounted on 4-12 inch diameter chucks. The master plate can be custom machined to fit any model chuck, making it a permanent universal fixture on any machine.When using this system, the transition from one job to the next simply requires bolting on a new size

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Universal quick change system for any chuck Repeatability < 0.001" TIR Reduce setup and changeover times by up to 80% Eliminate out of round conditions and concentricity problems DESCRIPTION When it comes to turning/holding smaller diameter parts Abbott’s precision master plate and segment system is an ideal choice for high changeover and short running jobs. Due to the system’s high repeatability, it is an excellent alternative to more expensive quick change chucks. The system consists of an aluminum master plate, similar to a thin Pie Jaw®, which is bored and bushed to accommodate Abbott’s standard, off-the-shelf pinned segments. Plates are available in 8, 10 and 12 inch diameters and can be mounted on 4-12 inch diameter chucks. The master plate can be custom machined to fit any model chuck, making it a permanent universal fixture on any machine.When using this system, the transition from one job to the next simply requires bolting on a new size or configuration of segments

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Reduce setup and changeover times by up to 80% Eliminate out of round conditions and concentricity problems Effectively double the holding capacity of any chuck without eliminating the ability to hold small parts Light-weight 713 Tenzaloy for weight saving DESCRIPTION Abbott‘s master plate and segment system is a great choice for turning larger diameter work pieces. The system consists of an aluminum master plate, similar to a thin Pie Jaw®, which is pre-drilled and keyed to accommodate Abbott’s standard, off-the-shelf segment rings. Plates are available in various diameters from 15 to 60 inches and can be mounted on 8-60 inch diameter chucks, effectively increasing the holding capability of smaller chucks. The master plate can be custom machined to fit any model chuck, making it a permanent universal fixture on any machine.When using this system, the transition from one job to the next simply requires bolting on a new size or configuration of segments

Request for a quote

TEXEL

United Kingdom

Improvement of life quality and monitoring of fitness achievements Medical scientific and research centers use 3D scanners to produce high accuracy digital models of the human body and its individual parts. Plastic surgeons, orthopedic surgeons, prosthetic care experts are in need of realistic 3D models. Medical workers no longer need to take measurements manually, to make models or do other routine and labor intensive work. Modern sensors will easily recognize body geometry, and special software will build a polygonal 3D model based on a cloud of dots generated in the process of scanning. The 3D scanning procedure is performed by a contactless method which takes less than a minute and is absolutely safe for human health. Scanners that generate a realistic 3D copy of a human body within seconds revolutionize medicine.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

INFOCUS ID LTD

United Kingdom

Direct thermal, thermal transfer, barcoding and receipt printers. Citizen, Zebra, Datamax, Toshiba, Wasp, Sato. Sales and service available, along with print heads and ribbons.

Request for a quoteResults for

Model making - Import exportNumber of results

7 ProductsCompany type