- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- drying equipment

Results for

Drying equipment - Import export

SWANWICK FOODSERVICE EQUIPMENT LTD

United Kingdom

We offer an extensive range of Electrolux and Alliance washing machines and laundry equipment to meet your exact requirements for washing machines, commercial dryers.

Request for a quote

SPARX MACHINE TOOLS

United Kingdom

The MCSB/2B-900 is a 900mm wide belt and brush/roll dry working Grindingmaster that is equipped with powerful motors allowing it to process the toughest and heaviest jobs around. R.P.M.1500 Hp/Kw15 + 7.5 kW Typical process applications covered by this machine: Stock removal of multiple individual parts and sheet materials Grain and scratch brush finishing of any material. Sizing and finishing of parts and sheet materials Deburring punched, nibbled, sheared or laser-cut sheet metal parts. Calibrating or keying carbon, rubber, wood or other soft materials.

Request for a quote

BIOPHARMA GROUP

United Kingdom

Benchtop Pro are compact research freeze dryers that encompass a range of lab processing requirements.They are flexible, powerful and user-friendly. Condenser temperature options from -55°C to -103°C to enable processing a wide range of products and solvents Extensive range of accessories allows for any shape or size sample to be freeze dried including trays, flasks, ampoules, vials and 96 well microtiter plates Range of manifolds in clear acrylic or stainless steel for superior corrosion resistance Precise vacuum control enables you to achieve better, more repeatable results. One-button auto start-up and shut-down activates all operating parameters in a correct and safe sequence, protecting the product and equipment Hot gas defrost and smooth-walled condensers for fast turnaround and minimal delay between runs

Request for a quote

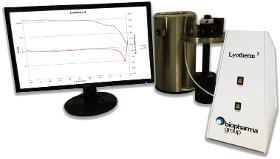

BIOPHARMA GROUP

United Kingdom

Frozen state solutions are a critical product stage or end product in a variety of industries, including freeze drying, pharmaceuticals, food storage and biotech. The Lyotherm3 combines electrical and thermal techniques. This unique dual analysis adds a new dimension to the data of this critical stage. Impedance Analysis (Zsinφ) is a fixed frequency dielectric analysis providing an indication of the sample tracks molecular mobility, including events not picked up by thermal methods like DTA or DSC Differential Thermal Analysis (DTA) measures the difference in temperature between a sample and a reference, highlighting exothermic and endothermic events e.g. crystallisation, eutectic melting and glass transitions Combining DTA and Impedance analysis means Lyotherm is more sensitive to changes within the frozen structure than other exclusively thermal techniques.

Request for a quote

BIOPHARMA GROUP

United Kingdom

The Lyostar3 operates a cutting edge R&D system, moving users away from the ‘trial-and-error’ elements during the development processes, toward unique SMART technology that enables fast and easy optimisation of cycles, and ensure the smooth transfer from laboratory- to production-scale. Independent studies have confirmed the use of SMART Freeze Drying Technology™ software from SP Scientific (available with the Lyostar), has offered a time reduction on an average cycle development in the order of 78%. The technology reduces the average cycle development to one or two runs, rather than the conventional series of six to eight runs – thereby not only reducing development time, but also lowering materials costs by at least one third.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

BIOPHARMA GROUP

United Kingdom

Every freeze-drying formulation has a critical temperature, below which it should be maintained during primary drying in order to prevent processing defects. The Lyostat freeze drying microscope allows observation of the sample structure during drying and heating so that the exact point of collapse can be determined. Innovative lighting and image capture systems (with articulated head for easy sample loading) provide sharp visualisation for easy, accurate identification of structural changes.

Request for a quote

BIOPHARMA GROUP

United Kingdom

Highly flexible and with multiple configurations, the Ultra is similar to the Genesis but with expanded capacity to enable those involved in small-scale production or scale-up research to process larger batches. Control options are available to provide cGMP and 21CFR11-compliant data monitoring, security restriction and automation applications, and stainless-steel cleanroom flanging and water cooling can be specified to allow Ultra to be used in controlled environments. The chamber can be isolated so that pressure rise tests can be carried out to give an indication of the end of primary or secondary drying. Additional vacuum gauges and product probes can be specified to provide in-depth process documentation for research or regulatory requirements. Ultra is commonly used by pharmaceutical, biotech and diagnostics companies. With shelf area up to 2.13m2 shelf area and condenser capacity up to 50litres, Ultra is often used for scale-up work and production.

Request for a quoteResults for

Drying equipment - Import exportNumber of results

8 ProductsCountries

Company type