- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- clamp-on

Results for

Clamp-on - Import export

1ST MACHINE TOOL ACCESSORIES

United Kingdom

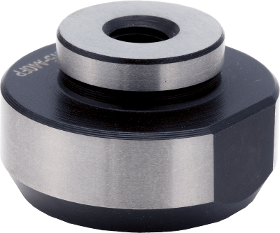

Reduce your set-up times by more than 90%. Self-clamping mechanism, constant air not required Made from heat treated refined steel Positioning slots allow for indexing by 90° Created for use on CNC machining centres, the V-Tech Zero Point system’s unique design guarantees the secure and precise clamping of workpieces, even under tough conditions. The pneumatic, quick change and ZERO POINT clamp features compact dimensions, extraordinarily high clamping force and is made from top quality materials. V-Tech clamping and location elements can be purchased individually to easily adapt workholding and fixtures for lightning fast changeovers. V-Tech receivers are also available as a . Each V-Tech receiver provides 24KN of clamping force and has positioning slots to allow for indexing by 90 degrees. The self-clamping mechanism means the force is still applied after the air has been disconnected.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Round, Hexagon, Square or Emergency types available Available in Smooth or Serrated Clamping tolerance of +/- 0.5mm Counter boring and special profile shapes are available upon request DC Varibore Collets have the same accuracy specification as spring collets whilst maintaining a gripping range of +/- 0.5mm. Supplied with either smooth or serrated gripping surface. Serrated collets are ideal for aggressive first operation gripping of rough bar work. Vulcanized rubber between the hardened steel collet segments provides excellent protection against coolant and chip ingress. Counter boring and special profile shapes are available upon request.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

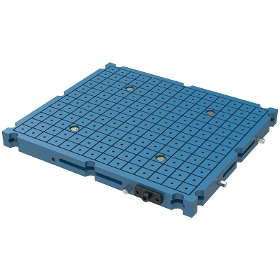

Can be used with or without pallet Can run from vacuum generator or dedicated pump Can be mounted on a magnet for grinding applications Matrix on top surface can be used for traditional clamping or part location DESCRIPTION Possibly the most universal multi-functional vacuum system in today’s market, this system has several unique features to meet your vacuum workholding needs. Each Multi-Power vacuum table has 4 ports to allow for multi component clamping. The top surface is textured for extra holding force and has a matrix of threaded holes to combine vacuum and traditional clamping methods as well as the ability to mount pallets. The bottom surface includes 6 embedded steel washers to allow the unit to be mounted on a magnet for grinding applications. The Multi-Power vacuum table can be equipped with multiple vacuum generators when additional holding force is required and multiple vacuum tables can operate from a single vacuum source.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

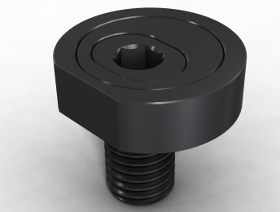

Low Profile for More Tool Clearance Cam-Profile allows for Part Size Variation Haredened for Longevitiy Low profile eccentric clamp has a long stroke allows for part size variation. Relatively high clamp force for size of the unit, low profile allows for holding smaller components and giving better tool clearance.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

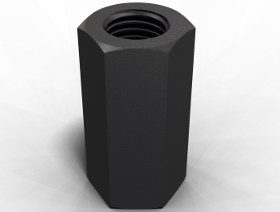

Extend the length of clamping studs Heat treated to HRC 30-35 Black Oxide surface finish Extends the length of clamping studs. These nuts are manufactured from S45C(JIS) / CK45(DIN) heat treated to HRC 30-35 and have a black oxide surface finish.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

1ST MACHINE TOOL ACCESSORIES

United Kingdom

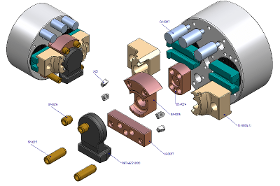

Uses the HSK-A type, time-proven tool holder shank to connect the head and the work-piece holder. Off-line setup in advance allows quick work-piece changing, minimizing machine downtime. Excellent workpiece accessibility Workpiece centralizing on flang work holders. Flange work holders These central bosses are used for workpiece location on the Klamp range of flange work holders.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Clamps and Pulls Down Component Available Ground or Serrated Low Profile Jaw for Thinner Components Vise mounted directly to the machine bed. Low profile jaw allows for more tool clearance. The actuation not only clamps the components but also pulls it down. The jaws are available in smooth or serrated. Parts CP15 and CP16 work as stop for this vise.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Quick and reliable workholding is essential and 1st MTA not only offers a vast range of standard equipment but also provides customised workholding solutions to suit individual application requirements. Such bespoke equipment can solve complex production problems or, in standard applications, substantially reduce set-up and idle times. 1st MTA’s aim is to provide: Extra Versatility Fewer Clampings Higher Efficiency, Accuracy and Repeatability These tailored solutions, wherever possible, will be based on components from the extensive standard range; by using this modular approach there are significant cost and time advantages to be gained and in the majority of cases successfully solutions are devised to problem components on this basis. However, MTA is just as happy to go back to basics and produce totally bespoke “one-off” items to meet customers requirements. Whichever method is used it will be securely based in the company’s wealth

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Ideal for Secondary Operations on lathe parts Clamp body made of mild steel for machinability Side screw clamping for blind holes Easily clamped in a lathe chuck The Side-Loc Xpansion Clamp is actuated from the side, making it perfect for blind hole applications. The Side-Loc Xpansion Clamp is designed in two styles, one for milling operations and one for lathe applications. The milling vesrion has a precision machined base for precise location in fixture plates and the lathe version has a 25.4mm shank for gripping in a chuck.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Ideal for Secondary Operations on lathe parts Clamp body made of mild steel for machinability Heat-treated and coated screw for long life Longer screws available for hydraulic applications The ID Xpansion™ clamp is the ideal solution to hold parts on an inside diameter for high density machining on vertical or horizontal machining centers. It can also be used as an expanding mandrel on a lathe. These machinable clamps are produced in 12 sizes and can hold internal diameters from under 5mm to almost 254mm. All are manufactured from 12L14 steel with black oxide coating except the largest diameter which is manufactured from 7075-T6 aluminum. The flange diameter of the clamp is held to a close tolerance for precision locating in a machined pocket on work cubes and fixture plates. The customer machines the mild steel clamp to match the bore of the part ensuring a proper fit.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

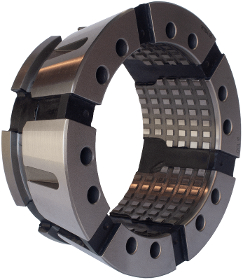

Can be used for 1st Operation only Deadlength Actuation Eleminates part movement when Clamping Case hardened, optimising the rigidity, strength and durability. Varibore Collets have a large range allowing for easy holding of Rough Bar Klamp CRS60 collet chucks are suitable for collets which have a large gripping range. Allowing the collet chuck to handle very rough and unfinished bar, preparing it for a high accuracy second operation. Workpiece remains in a fixed position during actuation, allowing for precise z-axis positioning. A tapered sleeve is pushed forward, compressing the collet and gripping the workpiece

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Can be used for 1st Operation only Deadlength Actuation Eleminates part movement when Clamping Case hardened, optimising the rigidity, strength and durability. Varibore Collets have a large range allowing for easy holding of Rough Bar Klamp CRS54 collet chucks are suitable for collets which have a large gripping range. Allowing the collet chuck to handle very rough and unfinished bar, preparing it for a high accuracy second operation. Workpiece remains in a fixed position during actuation, allowing for precise z-axis positioning. A tapered sleeve is pushed forward, compressing the collet and gripping the workpiece

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Equalising mechanism securely grips variable thickness Face Clamping Reduces distortion Lever finger chucks allow for large thin wall parts The Kitagawa FG series are speical design finger jaws which rotate in and down to clamp, this make them idela for holding flanges or other speical compounets. They also come with a equalisation mechanism for variable thickness. FG-A Series chucks are supplied with standard adapter plate setups.

Request for a quoteResults for

Clamp-on - Import exportNumber of results

15 ProductsCountries

Company type