- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- corrosion-resistant steels

Results for

Corrosion-resistant steels - Import export

DIXON GROUP EUROPE LTD

United Kingdom

Interchange Data: • European High-Flow Interchange • 1/4” interchanges with Coilhose Megaflow, CEJN 320, and Rectus 25KA/26KA • 3/8” interchanges with Rectus 27KA and Series 410 Materials: • Machined components are manufactured using solid Steel or Brass bar stock • Stainless Steel balls, retaining rings, and springs maximise corrosion resistance and extend service life • Steel componentry is plated using ROHS Compliant Trivalent Chrome. • 3/8” and 1/2” couplers constructed of Steel as standard with Steel tubular valves Seal Components: • Nitrile (Buna-N) pneumatically energised seals are standard, providing a temperature range of -40°C to +121°C (-40°F to +250°F)

Request for a quote

DIXON GROUP EUROPE LTD

United Kingdom

Interchange Data: • Bowes Interchange Bayonet Style • Interchangeable with Bowes 51000-Series, National Series ‘B’, Dixon Dixlock, MacDonald Quick-Action, Adlock Materials: • Machined components are manufactured using solid Steel, Brass, or 303 Stainless Steel bar stock • Phosphor Bronze retaining ring and spring maximise corrosion resistance and extend service life • Steel componentry is plated using ROHS Compliant Trivalent Chrome • Dust cap bead chain constructed of Stainless Steel Seal Components: • Nitrile (Buna-N) pneumatically energised seals are standard, temperature range -40°C to +121°C (-40°F to +250°F)

Request for a quote

DIXON GROUP EUROPE LTD

United Kingdom

Interchange Data: • Trufl ate Automotive interchange style • Parker 10-Series • Rectus 55KM • Tomco A2100/PT400 Materials: • Machined components are manufactured using solid Steel or Brass bar stock • Stainless Steel balls, retaining rings, and springs maximise corrosion resistance and extend service life • Steel componentry is plated using ROHS Compliant Trivalent Chrome • 1/4” couplers constructed of Brass with Steel sleeve and Steel tubular valve as standard • 3/8” and 1/2” couplers constructed of Steel as standard with Steel tubular valves Seal Components: • Nitrile (Buna-N) seals are standard providing a temperature range of -40°C to +121°C (-40°F to +250°F)

Request for a quote

DIXON GROUP EUROPE LTD

United Kingdom

Interchange Data: • Parker 20-Series Manual Interchange (F-Series) • Parker 30-Series Automatic Interchange (D-Series) • Foster 3, 4, 5, and 6 Series • Hansen 1000, 400, 500 (F-Series) • Hansen 3000, 4000, 5000, 6000 (D-Series) Materials: • Machined components are manufactured using solid Steel, Brass, or 303 Stainless Steel bar stock • Stainless Steel balls, retaining rings, and springs maximise corrosion resistance and extend service life • Steel componentry is plated using ROHS Compliant Trivalent Chrome • Automatic couplers constructed of Brass with Steel tubular valve as standard (3/8” to 3/4” couplers have Steel prong valves) • 1/4” manual couplers constructed of Brass with Steel sleeve and Steel tubular valve as standard • 3/8” and 1/2” manual couplers constructed of Steel as standard with Steel tubular valve. Seal Components: • Nitrile (Buna-N) seals are standard, providing a temperature range of -40°C to +121°C (-40°F to +250°F)

Request for a quote

DIXON GROUP EUROPE LTD

United Kingdom

Interchange Data: • Straight-Through Pressure-Wash Interchange • Parker ST-Series, Foster FST-Series, Tomco Series-ST, Hansen ST-Series Materials: • Machined components are manufactured using solid Steel, Brass, or 303 Stainless Steel bar stock. • Stainless Steel balls, retaining rings, and springs maximise corrosion resistance and extend service life. • Steel componentry is plated using ROHS Compliant Trivalent Chrome. • 1¼” to 2” Brass couplers have Steel sleeves as standard to maximise service life, hardened to resist deformation. • Steel nipples are hardened to provide heavy duty performance. Seal Components: • Nitrile (Buna-N) seals are standard, providing a temperature range of -40°C to +121°C (-40°F to +250°F)

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

DIXON GROUP EUROPE LTD

United Kingdom

Interchange Data: • Interchangeable to ISO15171-1 • Parker PD-Series, Aeroquip FD90, Tomco Series DK Materials: • Machined components are manufactured using solid Steel bar stock • Stainless Steel balls, retaining rings, and springs maximise corrosion resistance and extend service life • Steel nipples are machined from solid Steel bar stock and hardened • Steel componentry is plated using ROHS Compliant Trivalent Chrome Seal Components: • Nitrile (Buna-N) seals are standard, providing a temperature range of -40°C to +121°C (-40°F to +250°F) • PTFE anti-extrusion ring protects main coupler O-Ring from dynamic impulse pressure damage

Request for a quote

DIXON GROUP EUROPE LTD

United Kingdom

Interchange Data: • Interchangeable with Snap-Tite 71-Series Materials: • Machined components are manufactured using solid Steel or 316 stainless bar stock. • Stainless Steel balls, retaining rings, and springs maximise corrosion resistance and extend service life. • Steel componentry is plated using ROHS Compliant Trivalent Chrome. • Steel coupler sleeves are hardened to resist deformation and maximise service life. • Steel nipples are hardened to provide heavy duty performance. Seal Components: • Nitrile (Buna-N) seals are standard, providing a temperature range of -40°C to +121°C (-40°F to +250°F). • All couplers and nipples incorporate PTFE or TPC-ET anti-extrusion rings to protect the seal components from dynamic impulse damage.

Request for a quote

STALEVAR COMPANY LLC

United Kingdom

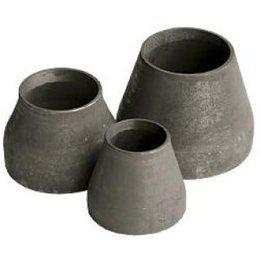

Pipeline fittings are installed when the direction of the pipeline changes during the installation process. Elbows are made of steel, steel with increased corrosion and cold resistance, alloy steel. Types of bends Steeply curved, seamless bends; Stamp welded steeply bent bends; Welded sectional bends; Cold rolled bends

Request for a quote

BRODER METALS GROUP LIMTED

United Kingdom

ASMS659 is a heat and corrosion resistant steel. We hold this grade in round bar form. The material is typically used for parts requiring good corrosion resistance which will be subjected to elevated temperatures during fabrication and service. The material is particularly good for parts requiring oxidation resistance up to 816oC. Material is supplied in the solution heat treated condition.

Request for a quote

BRODER METALS GROUP LIMTED

United Kingdom

ASMS659 is a corrosion resistant steel. We hold this grade in round bar form in both the solution treated condition (Condition A) and in the H1025 precipitation treated (aged) condition. The material is typically used for part s requiring corrosion resistance and high strength up to 300oC. The material exhibits good ductility and strength in the transverse direction in large section sizes SIZES STOCKED: Condition A – 9.5 mm dia – 152.4 mm dia H1025 condition – 12.7 mm dia – 152.4 mm dia

Request for a quote

ANOPOL LTD.

United Kingdom

A clean stainless steel surface will generate its own passive oxide layer when exposed to oxygen. It is this oxide layer that gives stainless steels their corrosion resistant qualities, it is possible however to accelerate the formation of this layer by chemical passivation.

Request for a quote

A J MARSHALL (SPECIAL STEELS) LTD

United Kingdom

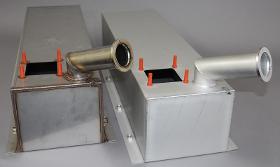

Stocked steel grades: CORTEN, COR-TEN A, COR-TEN B, S355J2WP+N, S355J2W+N, S355JOWP, S355JOW, S355J2W, PATINAX, ASTM A242, 1.8946, 1.8965. Anticorrosive weather resistant steel with increased atmospheric resistance by formation of a protecting oxidation layer. Unprotected usage (no painting) possible depending on environmental conditions. TYPICAL APPLICATIONS: Structures, architecture, sculptures (Angel of the North), cladding, landscaping, chimneys, bridges, water pipes, fans, exhaust systems, vehicles and equipment constructions. All steel is supplied with full mill test certificates to DIN EN 10204-3.1. Payment: L/C, T/T, Cheque, Transfer, Cash, VISA.

A J MARSHALL (SPECIAL STEELS) LTD

United Kingdom

Stocked steel grades: RAEX 400, RAEX 500, BRINAR 400, AR400, 20MnCr6-5. RAEX 400360-440HB3mm - 100mm+ RAEX 500450-540HB6mm - 50mm RAEX STEELS RAEX is a hot rolled hardened steel grade with excellent hardness and strength properties and is resistant to abrasion and extreme surface pressure. RAEX 400 extends the lifespan of machinery, decreases the impacts of wear in structural components and saves costs. Thanks to its high strength properties, RAEX allows innovative and environmentally sound product development. RAEX is easy to weld, cut and has reasonably good formability. TYPICAL APPLICATIONS: Buckets and cutting edges of earth-moving machines, wearing parts of mining machines, wearing parts of concrete mixing plants and wood processing machines, platform structures, feeders and funnels. All steel is supplied with full mill test certificates to DIN EN 10204-3.1. Payment: L/C, T/T, Cheque, Transfer, Cash, VISA.

Results for

Corrosion-resistant steels - Import exportNumber of results

14 ProductsCountries