- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- chucks

Results for

Chucks - Import export

1ST MACHINE TOOL ACCESSORIES

United Kingdom

For over half a century, Kitagawa products have inspired confidence in customers all over the world. The Kitagawa series of chucks is wide-ranging and so technologically advanced that we can offer solutions for all machining conditions, no matter how punishing. Manufacturing systems with exceptional quality controls ensure the production of highly precise and superior products, which guarantee trouble-free operation. Our unique innovations in workholding solutions, supported by highly specialised design teams and a proven history of excellence, shows our capacity to challenge the world of engineering.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

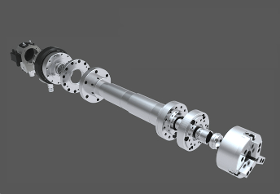

For example- Full System Chuck Adaptor Threaded Connector Drawtube Cylinder Adaptor Hydraulic Rotating Cylinder Anti Rotation Bracket Drain, Hoses and Fittings Part systems can be either: Front End- Chuck Adaptor Threaded Connector Drawtube Rear End: Drawtube Cylinder Adaptor Hydraulic Rotating Cylinder Anti Rotation Bracket Drain, Hoses and Fittings Or indeed any part(s) there of.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

No need to remove your 3 jaw or collet chuck Side actuated for thru or blind bores Use the same mandrels, sleeves and locators as the hydraulic systems A great option for low/medium-volume production. KEM Series includes a manually-operated expanding mandrel actuator incorporating a precision-ground 38mm diameter spigot for mounting in collet or jaw chucks. These models utilise the same precision mandrels, expanding sleeves and locators as our CNC Expanding Mandrels. They are side-actuated with an included square-drive key so that they can accommodate parts with blind bores as well as those with thru-holes. Precision-ground for high accuracy in squarenesss and concentricity, If higher accuracy is needed the mandrel can be clocked-in once the unit is gripped in a chuck.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Cross guide reduces runout and distortion Ideal for irregular shaped components Independent jaws allow for off centre holding Kitagawa chucks are manufactured from high grade alloy steel. The IC series are four jaw independent chucks with front mount holes. IC series chucks are supplied with a set of hard jaws.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

External gripping single piece jaws to suit Kitgawa's SC, JN and JS Series chucks.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Can be used for 1st and 2nd Operation Deadlength Actuation Eleminates part movement when Clamping Case hardened, optimising the rigidity, strength and durability. Uses 3 Different Types of Collet Klamp CRL60 collet chucks are suitable for spring, varibore and rubberflex collets increasing its flexibility. Varibore and rubberflex collets allow rough, unfinished bar to be machined in the first operation and spring collets can be used for high accuracy in the second operation. Workpiece remains in a fixed position during actuation allowing for precise z-axis positioning. A tapered sleeve is pushed forward, compressing the collet and gripping the workpiece. Maximum Capacity can be increased to 65mm using Rubberflex Collets

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Collets have a +/- 0.5mm range to handle rough bar Small nose diameter to provide excellent tool clearance. Case hardened, optimising the rigidity, strength and durability. Changing Collets usiong a gun reduces the change over time to seconds. Klamp DHP collet chucks are suitable for collets which have a +/-0.5mm gripping range. Allowing the collet chuck to handle rough and unfinished bar, preparing it for a high accuracy second operation. Due to the pullback nature of the DHP, it is only suited to bar work, the compact design means there is no position for a backstop. Changing collets via a quick change gun reduces the change over time to seconds

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Easy to use, installation time – less than one minute Suitable for round, square and hexagon spring collets Installed into the spring collet rather than the collet chuck, these stops are very easy to fit and adjust.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

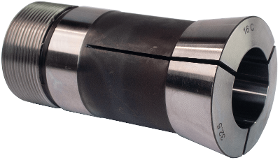

0.5mm and Imperial Increments also Available Accurate and Durable Suitable for 1st and 2nd Operation Work Handening ensures Longevity of Collets Available in a wide range of sizes 16C collets offer the user flexibility to do both first and second operation work using the same collet style. These collets are hardened and tempered to ensure flexibility and durability. The sizes below are in 1mm increments but we are able to supply both imperial and 0.5mm increments and even special sizes.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Can be used for 1st Operation only Deadlength Actuation Eleminates part movement when Clamping Case hardened, optimising the rigidity, strength and durability. Varibore Collets have a large range allowing for easy holding of Rough Bar Klamp CRS60 collet chucks are suitable for collets which have a large gripping range. Allowing the collet chuck to handle very rough and unfinished bar, preparing it for a high accuracy second operation. Workpiece remains in a fixed position during actuation, allowing for precise z-axis positioning. A tapered sleeve is pushed forward, compressing the collet and gripping the workpiece

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Can be used for 1st Operation only Deadlength Actuation Eleminates part movement when Clamping Case hardened, optimising the rigidity, strength and durability. Varibore Collets have a large range allowing for easy holding of Rough Bar Klamp CRS54 collet chucks are suitable for collets which have a large gripping range. Allowing the collet chuck to handle very rough and unfinished bar, preparing it for a high accuracy second operation. Workpiece remains in a fixed position during actuation, allowing for precise z-axis positioning. A tapered sleeve is pushed forward, compressing the collet and gripping the workpiece

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Small nose diameter to provide excellent tool clearance. Case hardened, optimising the rigidity, strength and durability. The gripping pull-back action to actuate the collet chuck means the work piece will be moved slightly in the Z-Axis. This is normally acceptable for first operation work and the work piece position can easily be determined with a facing cut. The 5C and 16C collets have been designed with a long small nose diameter allowing for good clearance for tooling. All collet closers are case hardened and ground optimising the rigidity, strength and durability.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Adjustable to suit 3 and 4 Segment Collets Used to insert and remove threaded collets. The number of segments the wrench suits can be easily adjusted

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Collets have a +/- 0.5mm range to handle rough bar Small nose diameter to provide excellent tool clearance. Case hardened, optimising the rigidity, strength and durability. Changing Collets usiong a gun reduces the change over time to seconds. Designed with a fixed length actuation system that ensures the collet is held stationary. Allowing the collet chuck to be used in bar feeding operations and highly accurate second operations. Klamp DHF collet chucks are suitable for collets which have a +/-0.5mm gripping range. Changing collets via a quick change gun reduces the change over time to seconds

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Collets have a +/- 0.5mm range to handle rough bar Small nose diameter to provide excellent tool clearance. Case hardened, optimising the rigidity, strength and durability. Changing Collets usiong a gun reduces the change over time to seconds. Klamp DHP collet chucks are suitable for collets which have a +/-0.5mm gripping range. Allowing the collet chuck to handle rough and unfinished bar, preparing it for a high accuracy second operation. Due to the pullback nature of the DHP, it is only suited to bar work, the compact design means there is no position for a backstop. Changing collets via a quick change gun reduces the change over time to seconds

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Bites into the Component for more Secure Gripping Stops Push Back or Movement in Jaws Screws can be used to Adjust Grip Length Case Handened for Longevity Gripper jaws can be a great way of getting round part movement in roughing operations, this is by use of teeth in the jaw which bite into the material. This biting can also be a great way to get round problems using black bar or other rough material. The depth of the backstop on the jaw can be adjusted by using screws, these screws are ground and hardened to give you a good backstop for the component.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Quicker change over of jaws compared to standard single piece jaws Kitagawa's soft two piece jaws to suit JN series scroll chucks with tongue and groove mounting.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Material can be Case Hardened Wide range of Heights and Lengths Custom Jaws also Available Aluminium cross tennon soft jaws to suit a 10 Inch power chuck. Jaws are manufactured from 6061 Aluminium. Good Quality of of material allows for machining with a good finish.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Compact short body design Increased max operating speed Increased pull force gives larger chuck range Kitagawa hydrualic cylinders are made with high grade alloy steel. The SS series cylinders are compact design to fit on size critical machines while giving a larger pull force to allow for operation of a wide range of chucks. The cylinder can be bought as a single unit or to suit a required machine under request.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Material can be Case Hardened Wide range of Heights and Lengths Custom Jaws also Available Steel serrated soft jaws to suit a 6 Inch power chuck. Jaws are manufactured from 080M15 Steel. Good Quality of of material allows for machining with a good finish.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Exceptionally long jaw stroke Secure gripping on large flange compounets Suitable for multi-diameter gripping Usefull for gripping irregular shaped componentsKitagawa chucks are manufactured from high grade alloy steel. The Kitagawa MLT series combines the advantages of level style and two jaw chucks, giving a perfect solution to abnormal flange work peices. MLT series chucks are supplied with blank drawnut and a set of t-nuts as standard.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Larger Bore to Accept Larger Components down the Spindle Compatible with large, readily available, range of jaws Upto 20% more speed and grip force than conventional chuck Industry Standard Large Bore 3 Jaw Chuck Kitagawa's chucks are manufactured from high grade alloy steel. Three jaw wedge style power chucks deliver up to 20% more speed, gripping force and bore size when compared to conventional chucks. The BB series has a big bore to accept larger components down the Spindle. BB200 series chucks are supplied with a blank drawnut as standard with a set of T-nuts.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

The Worlds Most Popular Chuck Compatible with large, readily available, range of jaws Upto 20% more speed and grip force than conventional chuck Standard Accessories AvailableKitagawa's chucks are manufactured from high grade alloy steel. Three jaw wedge style power chucks deliver up to 20% more speed, gripping force and bore size when compared to conventional chucks. These chucks are supplied with a spindle nose adaptor plate. B200A series chucks are supplied with a blank drawnut as standard with a set of T-nuts and an adaptor plate.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Included in this product range- 3 jaw closed centre power chucks- Ø630-1000mm master jaw serration 3/32” x 90° wedge type 3 jaw open centre power chucks- Ø630-1000mm master jaw serration 3/32” x 90° wedge type 3 jaw large diameter power chucks- closed centre: Ø1000-2000 activation through hydraulic cylinder built in or separated from the body manual regulation of the stroke of the jaws 2 + 2 large diameter power chucks- Ø630-2000mm 2 + 2 jaws with independent activation by hydraulic twin cylinder for clamping of irregular workpieces. lever type Large bore pneumatic chucks- Ø630-1000mm pneumatic cylinder built in the chuck body twin security valve in the chuck maintains the air pressure during machining even when the pressure is less than pre-set safety level safety pressure control device to stop the chuck rotation when a pressure loss is detected

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Since its founding in 1918, Kitagawa has established itself as a leader in the global supply of power chucks. As well as the standard power chuck range, there is the range Advanced chucks which includes Finger Chucks for the automotive industry. Kitagawa uses its experience to improve and maximise the effectiveness and efficiency of workholding products for the automotive industry, allowing it to provide customised products and solutions worldwide thereby optimising the customer’s manufacturing processes. There is a specialised team of engineers dedicated to customising Finger Chucks to suit your requirements, they offer meticulous attention to detail to provide an individual optimised solution based on your production facilities and requirements. In the increasingly competitive world of automotive wheels, Kitagawa Finger Chucks offer a solution you can trust.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Compatible with large, readily available, range of jaws Two stage gripping gives clamping and seating of part Base jaws do not protrude on z axis Sealed body designKitagawa chucks are manufactured from high grade alloy steel. The Kitagawa DL Series are the 1st chuck with two stage gipping action, firstly parallel clamping then pull back action for work seating.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Compatible with large, readily available, range of jaws Two stage gripping gives clamping and seating of part Base jaws do not protrude on z axis Sealed body design Kitagawa chucks are manufactured from high grade alloy steel. The Kitagawa DL Series are the 1st chuck with two stage gipping action, firstly parallel clamping then pull back action for work seating.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Centre Cover protects from Swarf Entering Inside the Chuck Replacement dust cover to suit a B200 power chuck. The cover plate is used to protect the internal parts of the chuck from swarf ingress.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Threaded Hole allows for Back Stop to be fitted Tight fit by use of an o-ring Chuck bungs are primarily used to block the centre of the chuck to stop swarf and coolant going down the spindle. The threaded hole which can be used for the removal of the bung can also be used for mounting a back stop.

Request for a quoteResults for

Chucks - Import exportNumber of results

57 ProductsCountries

Company type