- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- change machines

Results for

Change machines - Import export

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Uses the HSK-A type, time-proven tool holder shank to connect the head and the work-piece holder. Off-line setup in advance allows quick work-piece changing, minimizing machine downtime. Accepts a variety of workholders Excellent workpiece accessibility In the case where you can’t mount the head directly to your machine table, please use this mounting plate. We can supply a blank that is customisable and also manufacture a special mounting plate just for you. For more information, please feel free to contact us.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

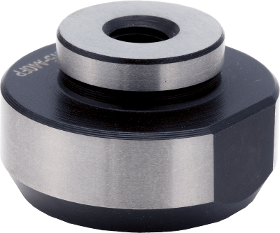

Uses the HSK-A type, time-proven tool holder shank to connect the head and the work-piece holder. Off-line setup in advance allows quick work-piece changing, minimizing machine downtime. Excellent workpiece accessibility Workpiece centralizing on flang work holders. Flange work holders These central bosses are used for workpiece location on the Klamp range of flange work holders.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Change jaws in seconds and complete a full setup in a few minutes Precise loction of jaws means your datum is preserved every time you remove the jaws. Once a job is setup, it stays setup. Machinable workholding means complex shaped workpieces are easy to grip Single station jaws can grip larger workpieces with just a quick jaw change Single Station Machinable Jaw Sets increase the flexibility of your system by eliminating the need to completely switch fixtures for jobs requiring greater holding capacity. Simply QwikChange the jaws and the set-up is ready in minutes. These jaws are compatible with 1030 Qwik-loks and 1030 Multi-Loks and are available in a range of sizes. All jaws are available as sets or individually.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Uses the HSK-A type, time-proven tool holder shank to connect the head and the work-piece holder. Off-line setup in advance allows quick work-piece changing, minimizing machine downtime. Excellent workpiece accessibility The dovetail clamping work-holder with the HSK head works with heavy-duty milling. All Swift Klamp Dovetail work holders are attached to the workpiece usinga simple dovetail. Setup is quick, easy and dovetail work holders only require the minimum of material to hold the workpiece. That means less waste, easy preparation, and no distortion to the workpiece.Dovetail machining of the work-piece clamping area using an angular cutter is required prior to machining

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Change machines - Import exportNumber of results

4 ProductsCountries

Company type