- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- ultrasonic testing

Results for

Ultrasonic testing - Import export

CYGNUS INSTRUMENTS LTD

United Kingdom

Combining intelligent, advanced software and electronics with a truly simple to use interface, the Cygnus Flooded Member Detector (FMD) is an easy to use, cost effective and reliable system. The FMD system comprises three fundamental parts the probe and probe handler, the subsea electronics unit and the reporting software. The probe handler selfaligns and ensures correct contact with the member, even when approached from an angle. The subsea electronics unit is available in high grade acetal or stainless steel for the harshest environments. The reporting software displays a simple DRY or FLOODED result and Ascans for verification; and logs results for offline analysis or reports exported as PDF or Excel. As with all Cygnus ultrasonic testing equipment, the FMD is extremely easy to learn and understand, and can be used by a range of operators with varying experience.

Request for a quote

CYGNUS INSTRUMENTS LTD

United Kingdom

Cygnus ultrasonic hatch cover weathertightness tester has been ABS type approved and accepted by P & I clubs. This ultrasonic hatch cover testing device is used to perform quick and effective evaluation of cargo hold hatch covers and door seals to determine water leaks and weathertightness. This ultrasonic leak detection system allows inspections to be carried out with cargo in place or in subzero temeprature, replacing traditional and unreliable methods such as hose testing. The Cygnus Hatch Sure system comprises of 2 parts a battery powered transmitter containing 19 ultrasound emitters (40 kHz) which are arranged to produce an omnidirectional sound field uniformly distributed throughout the cargo hold; and a receiver which displays the sound energy level that passes through gaps in the enclosed cargo hold to enable the location of leaks to be quickly and accurately identified.

Request for a quote

ATLAS MATERIAL TESTING TECHNOLOGY GMBH

Germany

The Atlas SUNTEST XXL+ FD is a large state-of-the-art xenon flatbed instrument. It’s completely target designed to meet the testing needs of the FMCG industry, such as drinks, foodstuffs, personal care or household products. XXL+ FD enables consumer goods manufacturers to test their products realistically within very short test times, typically with acceleration factors between 10-30 versus real time. It’s for reliable qualification of stable product formulations, determination of appropriate packaging materials, and supporting product shelflife claims. 3x 1700 W air-cooled Xenon Lamps 3000 cm 2 exposure area Touch screen with colour display to monitor and display test parameters Measurement and Control of Irradiance 300-400 nm / 340nm or 420nm Measurement and Control of Black Standard (BST); (Black Panel optional) Measurement and Control of Chamber Temperature Display of Diagnostic Messages Storage for 10 user-defined test methods Pre-programmed international standard test method Multilingual User Interface Control Panel tiltable for increased operating comfort Thermal insulation of test chamber and periphery preventing water condensation Temperature control selectable either via CHT (15° * - 70 °C; *with chiller) or via CHT and BST (25° * - 100 °C; *with chiller) simultaneously (dual control) Adapted chiller SunCool XXL+ for testing at low temperatures in the range 15-30°C CHT; detachable for standard weathering testing needs Ultrasonic humidification system for controlled humidity during operation without SunCool Specimen spray system with integrated 60 l water reservoir for spray cycles at 25°C ** - 70°C Static, horizontal exposure area for flat or 3D specimen Test chamber with 5 ° slope for optimum spray water drain Access port ca. 3,0 x 2,5 cm for potential use of additional external sensors inside the test chamber Light cassette including non-ageing aluminium reflector, coated quartz filter and slot for additional optical filters Switch-off by radiant exposure, light exposure time or total operating time Advanced Auto Start functions Data output via Memory Card or RS 232 Ethernet interface plus XenoTouch Add-ons 1, 2, and 3 (“Remote Control“, “E-Mail Service“, “Online Monitoring“) Sliding sample table for easy specimen loading; exposure area (WxD) 74 x 37 cm

KIGEMA SP. Z.O.O

Poland

We maintain quality assurance systems, such as iso 9001: 2009, iso 18001-2004 and iso 14001-2005. KIGEMA possesses a laboratory allowing testing the mechanical properties of products like hardness, elongation, and micrometer. KIGEMA also conducts penetration and ultrasonic tests and issues certificates of conformity with EN 10204-2.2, 2.3, 3.1B. Additionally, the company has an air-conditioned measuring room equipped with High-quality measuring equipment, which is regularly calibrated. The measuring equipment includes: calipers, altimeter, depth calipers, inside micrometers, bore gauges, outside micrometer and roughness tester.

Request for a quote

ETH MESSTECHNIK GMBH

Germany

Customized Solution Component supply and emissions over hand-operated turret Application Quality assurance in the electronics industry. Batch testing; Test equipment for testing and optimization of weld two part housings of SMD components. Batch testing; Test device for checking and optimizing the welded connection on two-part housings of SMD components. Test device for small SMD parts Documentation of the maximum torque achieved and the tear-off angle. Documentation of the maximum achieved torque and angle of demolition.

Request for a quote

INOTECH MACHINING SRL

Romania

INOTECH MACHINING supplies also stainless steel welded parts and assemblies. Our team of qualified welders can weld large components and also highly complex small parts. Welding methods: - MIG-MAG and TIG (WIG). Capabilities: - We own a workshop hall of 6.000 sqm. - With cranes capacity of up to 50 tones. - Stress relieving treatment - Thermal or Vibrations. We ensure all of our products meet the highest standards through rigorous quality checks: - Penetrating liquids, magnetic powders, or ultrasonic tests, if needed. - Geometrical control in place with laser tracking.

Request for a quote

INOTECH MACHINING SRL

Romania

Our team of qualified welders can weld large components and also highly complex small parts of steel. Welding methods: - MIG-MAG and TIG (WIG). Capabilities: - We own a workshop hall of 6.000 sqm. - With cranes capacity of up to 50 tones. - Stress relieving treatment - Thermal or Vibrations. We ensure all of our products meet the highest standards through rigorous quality checks: - Penetrating liquids, magnetic powders, or ultrasonic tests, if needed. - Geometrical control in place with laser tracking.

Request for a quote

INOTECH MACHINING SRL

Romania

Our team of qualified welders can weld large components and also highly complex small parts of steel. Welding methods: - MIG-MAG and TIG (WIG). Capabilities: - We own a workshop hall of 6.000 sqm. - With cranes capacity of up to 50 tones. - Stress relieving treatment - Thermal or Vibrations. We ensure all of our products meet the highest standards through rigorous quality checks: - Penetrating liquids, magnetic powders, or ultrasonic tests, if needed. - Geometrical control in place with laser tracking.

Request for a quote

INOTECH MACHINING SRL

Romania

Our team of qualified welders can weld large components and also highly complex small parts of steel. Welding methods: - MIG-MAG and TIG (WIG). Capabilities: - We own a workshop hall of 6.000 sqm. - With cranes capacity of up to 50 tones. - Stress relieving treatment - Thermal or Vibrations. We ensure all of our products meet the highest standards through rigorous quality checks: - Penetrating liquids, magnetic powders, or ultrasonic tests, if needed. - Geometrical control in place with laser tracking.

Request for a quote

INOTECH MACHINING SRL

Romania

Our team of qualified welders can weld large components and also highly complex small parts of steel. Welding methods: - MIG-MAG and TIG (WIG). Capabilities: - We own a workshop hall of 6.000 sqm. - With cranes capacity of up to 50 tones. - Stress relieving treatment - Thermal or Vibrations. We ensure all of our products meet the highest standards through rigorous quality checks: - Penetrating liquids, magnetic powders, or ultrasonic tests, if needed. - Geometrical control in place with laser tracking.

Request for a quote

INOTECH MACHINING SRL

Romania

Our team of qualified welders can weld large components and also highly complex small parts of steel. Welding methods: - MIG-MAG and TIG (WIG). Capabilities: - We own a workshop hall of 6.000 sqm. - With cranes capacity of up to 50 tones. - Stress relieving treatment - Thermal or Vibrations. We ensure all of our products meet the highest standards through rigorous quality checks: - Penetrating liquids, magnetic powders, or ultrasonic tests, if needed. - Geometrical control in place with laser tracking.

Request for a quote

INOTECH MACHINING SRL

Romania

INOTECH MACHINING supplies also stainless steel welded parts and assemblies. Our team of qualified welders can weld large components and also highly complex small parts. Welding methods: - MIG-MAG and TIG (WIG). Capabilities: - We own a workshop hall of 6.000 sqm. - With cranes capacity of up to 50 tones. - Stress relieving treatment - Thermal or Vibrations. We ensure all of our products meet the highest standards through rigorous quality checks: - Penetrating liquids, magnetic powders, or ultrasonic tests, if needed. - Geometrical control in place with laser tracking.

Request for a quote

INOTECH MACHINING SRL

Romania

INOTECH MACHINING supplies also stainless steel welded parts and assemblies. Our team of qualified welders can weld large components and also highly complex small parts. Welding methods: - MIG-MAG and TIG (WIG). Capabilities: - We own a workshop hall of 6.000 sqm. - With cranes capacity of up to 50 tones. - Stress relieving treatment - Thermal or Vibrations. We ensure all of our products meet the highest standards through rigorous quality checks: - Penetrating liquids, magnetic powders, or ultrasonic tests, if needed. - Geometrical control in place with laser tracking.

Request for a quote

INOTECH MACHINING SRL

Romania

INOTECH MACHINING supplies also stainless steel welded parts and assemblies. Our team of qualified welders can weld large components and also highly complex small parts. Welding methods: - MIG-MAG and TIG (WIG). Capabilities: - We own a workshop hall of 6.000 sqm. - With cranes capacity of up to 50 tones. Stress relieving treatment - Thermal or Vibrations. We ensure all of our products meet the highest standards through rigorous quality checks: Penetrating liquids, magnetic powders, or ultrasonic tests, if needed. Geometrical control in place with laser tracking.

Request for a quote

DÜRR NDT GMBH & CO. KG

Germany

DRIVE NDT is a cloud-based management software which integrates all NDT inspection methods and associated processes into a single system. With DRIVE NDT you can organize and control the complete NDT job workflow including individual test reports, staff, customer and device management, and much more. One solution for all NDT inspection methods Radiographic Testing (RT-D, RT-F, CT) Ultrasonic Testing (UT-PA, UT-TOFD, UT-WD) Visual Testing (VT) Electromagnetic Testing (ET) Magnetic Particle Testing (MT) Liquid Penetrant Testing (PT) Acoustic Emission Testing (AT) Acoustic Resonance Testing (ART) Infrared/Thermal Testing (IR/TT) Leak Testing (LT) Optical Methods (OM) ...

Request for a quote

AKROMAK METAL DIŞ TIC. LTD. ŞTI.

Turkey

Destructive and non-destructive tests can be carried out on request in accordance with the applicable standards. Destructive tests to determine mechanical properties : tensile test impact test Non-destructive tests to examine the internal and surface condition of the castings: visual inspection (VT) Magnetic particle testing (MT) Ultrasonic testing (UT) Penetrant Testing (PT) Radiographic testing (RT)

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

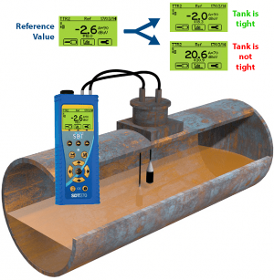

SDT ULTRASOUND SOLUTIONS

Belgium

Peace of mind and reassurance for the operator Tightness Testing on Underground Storage Tanks and other Air Tight Compartments The ability to test for tightness with an ultrasound detector is extremely powerful and versatile. It is the only way to ensure that underground storage tanks are air tight. But that isn’t all that ultrasonic tightness testing can be used on. There are many things that need to be air tight. Like the engine or cabin of a car, large shipping containers or the bearing housing in a paper production plant. When somethings tightness integrity deteriorates one or two things can happen. Things can leak out, or things can get in. And whenever possible, it is advantageous to avoid either of these from happening. Fuel Leaking From Underground Storage Tanks Damage the Environment and Waste Valuable Resources Overtime the tightness integrity of underground storage tanks or other air tight compartments can deteriorate.

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

The welding process is one of the core ways in which we manufacture precision tubes. Our high-quality tubing starts off as a flat strip of metal. The strip is formed into a tube through a series of rollers and the join, also called the seam, is then welded together. Welded Processes Special non-destructive testing methods – including eddy current, ultrasonic and pressure testing - are used to ensure a consistent weld. Just like with seamless manufacturing, welded tubes can be drawn down by plug drawing or sinking. This method can be used to create very long lengths of coiled tube, these can also be measured during coiling using a laser measurement. The main welded tube manufacturing processes used are strip welding and cold drawing, but other important processes in between, or at the end of the drawing process, include Please note that we have a minimum order value of £10,000.

Request for a quote

GL MARINE SURVEYORS S.R.L.S.

Italy

The basic equipment consists of an ultrasound generator, which is placed in the hold, and a receiver unit fitted with a microphone to receive the emitted ultrasound signals. It is a non-destructive method, non -invasive, can be used in all weather conditions, and can be used with cargo inside the hold.

Request for a quote

SONATEST LTD

United Kingdom

The Wave ultrasonic flaw detector innovative solution is suitable for a wide range of industrial applications from manufacturing to service engineering.

Request for a quote

SIM AUTOMATION GMBH

Germany

- Quality control and safeguarding - Individual test values and criteria - Customer-specific measuring and testing plants - Single measuring systems with manual assembly - Fully integrated and automated testing plants using robots - Optical, acoustic or electrical systems with/ without parts contact, data preparation, analysis Measuring and testing systems we were involved in: - Camera systems with corresponding image processing - Part recognition, positioning, color and surface examination, checking for damages - Optical / tactile / ultrasonic tests using sensors and displacement measurement systems - Leakage and pressure tests - Inspection and monitoring of filling level - Run-out properties and accuracy - Backlash measurement - Electrical tests and measurements - Electrical values, check measurements, switching and opening properties Used in all branches: e.g. pharmaceuticals industry, medical engineering, cosmetics, electronics and automotive industries.

Request for a quote

SIM AUTOMATION GMBH

Germany

The product portfolio at SIM Automation ranges from the effective design of individual manual workstations all the way through to completely interlinked, highly automated process lines. We handle all common transfer systems and can thus offer solutions that are independent from the branches of our customers. In addition to all standardized joining, measuring, testing and inspection systems, our assembly plants can also implement the customer’s own processes, including: - Joining, screwing, bonding, riveting, welding (laser, ultrasonic, resistance) - Testing, measuring, inspecting (optical, tactile, electrical, thermal) - Robot systems - Linear systems (pneumatic, electrical, mechanical) - Cam-controlled drives, linear and handling systems Testing and inspection lines we have been involved in: - Electric high-performance gear components (up to 6 kV) - Electric central locking systems (vehicles)

Request for a quote

FLUKE DEUTSCHLAND GMBH

Germany

Leak detection in the age of digitalization SONOCHEK is a digital ultrasonic testing device to detect inaudible waves and frequencies in the air or in a metal machine frame. It is primarily used to detect leaks in any industrial air and gas pressure pipes and vacuum systems. Leaks of compressed air and gas systems in particular can be very costly because more energy needs to be produced to compensate for the loss. Its detecting range reaches from 20 up to 100 kHz. These frequencies are inaudible to human ears, but SONOCHEK can detect them and make them audible and visible, while specifying the leak and evaluating the total amount of loss, all of which can be combined in a full report. An integrated camera and microphone enable the engineer to comment on his findings and refine the final report.

Request for a quote

ATTEC ULUSLARARASI DIS TICARET A.S.

Turkey

CYLINDER TUBES (HPS & HPZ) •EN 10305-1 (HP) •EN 10305-2 (HPZ) •EN 10305-2 (HPS H9) Seamless, cold-drawn HP precision steel tubes EN 10305-1 Seamless, cold-drawn HPZ tubes have the best dimensional tolerances, plus excellent straightness and roundness. These tubes are thus excellently suited to peeling or honing. A recommended ultrasonic test can also be carried out for a surcharge Facts and Figures Diameter (OD)50,0 mm – 125,0 mm Wall thickness (WT)5,0 mm – 7,5 mm MaterialE355 Treatment condition+SR TestsEddy current testing EN 10893-2 extra charged: Ultrasonic testing EN 10893-10 ATTEC Uluslararasi Dis Ticaret A.S. Barbaros Mah. Mor Sumbul Sk Varyap Meridian I Blok No: 1 Kat:17 D:238 Atasehir 34746 Istanbul/Turkiye Mr.Ahmet Becenoglu Export Marketing Manager Tel: +90 216 488 88 90 – 98 Fax:+90 216 488 98 38 Gsm:+90 532 787 90 89

Request for a quote

ATTEC ULUSLARARASI DIS TICARET A.S.

Turkey

PRECISION STE EL TUBES •EN 10305-1 •EN 10305-2 •EN 10305-3 •EN 10305-4 (HPL) •EN 10305-5 Seamless, cold-drawn precision steel tubes EN 10305-1 Seamless, cold-drawn precision steel tubes have a particularly high dimensional tolerance with regard to the outer and inner diameter and/or the wall thickness. T Facts and Figures Diameter (OD)4 mm – 125 mm Wall thickness (WT)0,5 mm – 13,0 mm MaterialE215, E235, E255, E355, C35E, C45E 16Mo3, 25CrMo4, 42CrMo4, 25CrMo4 other materials upon request Treatment condition+C +LC, +SR, +A, +N TestsEddy current testing EN 10893-2 extra charged: Ultrasonic testing EN 10893-10 ATTEC Uluslararasi Dis Ticaret A.S. Barbaros Mah. Mor Sumbul Sk Varyap Meridian I Blok No: 1 Kat:17 D:238 Atasehir 34746 Istanbul/Turkiye Mr.Ahmet Becenoglu Export Marketing Manager Tel: +90 216 488 88 90 – 98 Fax:+90 216 488 98 38 Gsm:+90 532 787 90 89

Request for a quoteResults for

Ultrasonic testing - Import exportNumber of results

27 ProductsCountries

Company type

Category

- Welding work - steels and metal (8)

- Ultrasonic measuring equipment (4)

- Automation - systems and equipment (2)

- Measurement - Equipment & Instruments (2)

- Monitoring and control equipment (2)

- Pipes and tubes, stainless steel (2)

- Casting, steel (1)

- Foundries - copper, bronze and brass (1)

- Marine surveyors (1)

- Measurement and control instruments (1)

- Non-destructive tests (1)

- Pipes and tubes, steel (1)

- Quality control and certification (1)

- Software (1)

- Steels and metals - welding and brazing (1)

- Testing equipment (1)