- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- filling and sealing

Results for

Filling and sealing - Import export

NHM LIMITED

Ukraine

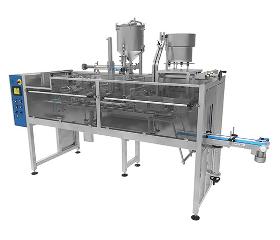

TECHNICAL DATAPARAMETER Speed, max.50 pouches/min. Filling volume, cm3100 – 1000 ml. (depending on filler) Type of packageready “”Doypack” pouch Packet width, max.200 mm Packet length, max.350 mm Electricals220 V, 50 Hz Power, kW1,5 Air consumption, l/min (0.6 Bar)460 Dimensions, mm2530x970x2190 Weight, kg850 WORKING PRINCIPLE Packaging machine grips empty “Doypack” pouch from a magazine, opens it, fills the product, prints date & seals the pouch. With the help of an orientator (optional) it can orientate and feed spouts to the sealing area and seal the spout vertically on to the pouch. Machine is equipped with parts for working with pouches of one width size. PRODUCTS TO BE PACKED: Food products: mayonnaise, condensed milk, jam, ketchup, tomato paste, sauces, tea, coffee, milk powder, rice, juices, cooking oil, etc. Non-food products: shampoo, liquid cleaning agents, fertilizers, cosmetic cream, window washer, toothpaste, washing powder, etc.

Request for a quote

NHM LIMITED

Ukraine

Automatic stacking system is an automatic system used for automatic counting and crating of polyethylene (LDPE) pouches in containers (polyethylene or carton cases). This system can be integrated into the working line with a Vertical Form-Fill-Seal (VFFS) packaging machine of any make. SPECIFICATIONVALUE PACKED PRODUCTPolyethylene pouches POUCH TYPEPillow pouch TYPE OF STACKINGIn bulk at 3 points PRODUCTIVITY*, MAXUp to 600 cases / hour RANGE OF POUCHES COUNTING IN A BOXFrom 1 to 99 pouches (depending on case and pouch dimensions) ELECTRICAL POWER (MAXIMUM)0.4 Kw, 380±4% V (3 phase), 50 Hz AIR CONSUMPTION~ 0.8 m3/hour WEIGHT~ 160 kg

Request for a quote

TECHNOWAGY LTD

Ukraine

Device components and operation principle The automatic machine for packing pellets in packages of polyethylene tape is equipped with a double-flow weighing dozer and independently forms a 3-seam package of polyethylene tape and pour in it ready dose of pellets, the package is sealed, cut off and step-by-step conveyed by the receiving transporter. The machine is equipped with a high-quality control system, which consists of the best components from Europe and is based on PLC Siemens. The machine is controlled using a touch-screen installed on the front of the control panel. From this display, you can monitor and configure the operation of the machine. All the parameters (like dose mass, dosing mode etc) are set at one terminal.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Filling and sealing - Import exportNumber of results

3 ProductsCountries

Company type