- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- electric controls

Results for

Electric controls - Import export

KOMFORTVAM

Ukraine

ADVANTAGES: -fast transformation of an open summer playground into a warm winter one; -more efficient ventilation of the room while maintaining heat inside; -use of the system for effective protection against wind; - the zone of parking of shutters in the lower position forms a fence for zoning and safety; - parking of shutters in the top position frees up space for free movement; -possibility to use a choice of single tempered glass or energy-saving glass; - vertical movement of shutters by means of the electric drive; -control of systems by means of the panel, both all simultaneously, and separately.

Request for a quote

AKTAPROM

Ukraine

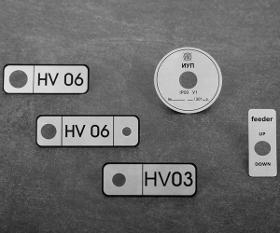

Push buttons are widely used in different spheres, especially in industrial sphere. This is electrical component, that can make or break electrical circuit. Thus it controls different electrical processes, starting from the simplest lamp and proceeding with complex machine lines. Generally, push buttons are made in a round shape to fit the human finger. We would like to offer different overlays for push buttons, which are considered to be indispensable part for control/facial panels. These overlays are stuck on the button surface and indicate distinctly their application. It helps the operator to anderstand all commands visually. Our company has its own production of marking items based upon own anodized aluminum method named Alumaproof.

Request for a quote

UTF

Ukraine

Capacity: 100-500 kg/h Energy source: electricity Control system is carried out with controller and TOUCHSCREEN Key features of the production line: - the length of production line depends on product range from 4.5m up to 10.0m - wide range of products due to replaceable units: feeding of liquid fillings sprinkling with sugar, poppy seeds, sesame, etc. twisting in a roll one- and multiple folding surface cuts Equipment set of the line: - forming table - calibrator - cutting unit - a sprinkler of loose ingredients with a humidifier and pressure roller - depositor of liquid filling - folding nodes - guillotine

Request for a quote

UTF

Ukraine

Capacity: 100-500 kg/h Quantity of dough layers: up to 288 Raw materials: flour Energy source: electricity Control system is carried out with controller and TOUCHSCREEN Key features of the production line: - equipment set of the production line depends on required quantity of layers - automatic batching of components - multiple rolling of the dough creates an ideal layered structure with a uniform distribution of the fat layer between the layers - comfortable access to the units and mechanisms which is contacting with dough, for maintenance and cleaning - production line can be designed according customer’s production premises Equipment set of the line: - dough ribbon extruder - calibrator (2 pcs.) - extruder of fat - rolling unit (2 pcs.) - multiroller (4 pcs.) - laminator (2 pcs.)

Request for a quote

UTF

Ukraine

Capacity: 100-500 kg/h Quantity of dough layers: up to 288 Raw materials: flour Energy source: electricity Control system is carried out with controller and TOUCHSCREEN Key features of the production line: - automatic batching system of raw materials is foreseen - wide varaity of products provided by replacable units of forming machine: feeding liquid filling sprinkling by sugar, sesame, poppy rolling in a roll one- and multiple rolling notching on surface - design of lines can be developed according to customer’s production premises Equipment set of the line: - lamination line with fat extruder - forming line - tunnel oven - conveyors system for cooling and packing

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

UTF

Ukraine

Capacity: 100-300 kg/h Raw material: flour Energy source for oven: electricity Control system is carried out with controller and TOUCHSCREEN Key features of the production line: - additional unit for rolling specially for producing taralli - replaceable dies for different diameters of product - option for additional equipment: dough feeding into extruder automatic system sprinkler unite (poppy, sesame ect.) automatic stacking system on baking trays - design of lines can be developed according to customer’s production premises Equipment set of the line - flour batcher - inclined conveyor - dough ribbon extruder - multiroller - feeding conveyor with knife mechanism - forming machine - machine for trays feeding - unite for dough base stacking - gilliotine

Request for a quoteResults for

Electric controls - Import exportNumber of results

7 ProductsCountries

Company type