- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- industrial equipment

Results for

Industrial equipment - Import export

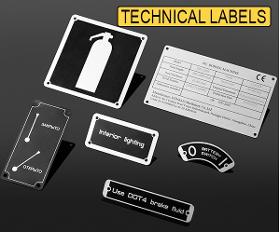

AKTAPROM

Ukraine

We produce technical labels based upon anodized aluminum method for the greatest variety of industries and organizations. Our labels will help you to identify and promote your goods all over the market. We create product specifications upon requirements of our clients. We understand that every label logo should be unique one for our customers to get more advantages for their products distribution all over the world. Technical aluminum labels are widely used for sticking on different equipment and its separate parts, especially it concerns electrics and its different parts, so as in accordance with safety rules, oracal labels are prohibited. In case the equipment is operated under severe conditions: high temperatures, different acids, abrasives, constant UV rays etc., it is relevant to use wear-resisting labels based upon anodized aluminum Alumaproof technology.

Request for a quote

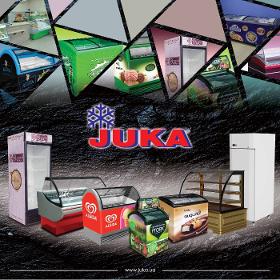

JUKA-INVEST LTD

Ukraine

Our assortment includes the following ranges: -Display freezers with curved and flat glass sliding lids; -Display freezers of bonnet type; -Chest freezers with solid doors; -Scooping freezers for gelato; -Freezing and cooling upright cabinets with glass and solid door; -Gastronomic refrigerated showcases; -Pastry counters.

Request for a quote

BROVARNI

Ukraine

Cost of equipment: Base equipment Two-units brewhouse for 1000 litersBH-10001 pcs.22800,00 Roller malt mill 300 kg/hRM-3001 pcs.1340,00 Plate sanitary wort chiller for wort cooling HE-1000HE-10001 pcs.1680,00 CIP-station for tanks up to 1000 liters and beer kegsCIP100(2)-K1 pcs.3900,00 Beer Glycol Chiller for Fermentation Tanks Cooling CH-12CH-121 pcs.7860,00 Cost of base equipment:71880,00 € Additional equipment Hot water tank at 2000 litersHWT-20001 pcs.6100,00 Cold water tank at 2000 litersCWT-20001 pcs.6800,00 Cost of additional eqiupment:12900,00 € Cost of complete set:84780,00 € Electricity consumers: Two-units brewhouse – 64 kWt Roller malt mill – 1.5 kWt CIP-station – 6.1 kWt Beer Glycol Chiller – 4.5 kWt Hot water tank – 13 kWt

Request for a quote

BROVARNI

Ukraine

Cost of equipment: Base equipment Roller malt mill 150 kg/hRM-150 Two-units brewhouse for 300 litersBH-300 CCT at 300 litersCCT-300 Plate sanitary wort chiller for wort cooling HE-300HE-300. CIP-station for tanks up to 600 liters and beer kegsCIP60(2)K Beer Glycol Chiller for Fermentation Tanks Cooling CH-6CH-6 Cost of base equipment:41830,00 € Additional equipment Hot water tank at 600 litersHWT-600 Cold water tank at 600 litersCWT-600 Cost of additional eqiupment:6950,00 € Cost of complete set:48780,00 € Electricity consumers: Roller malt mill – 1.5 kWt Two-units brewhouse – 23 kWt CIP-station – 3.8 kWt Beer Glycol Chiller – 3 kWt Hot water tank – 5 kWt

Request for a quote

BROVARNI

Ukraine

Cost of equipment: Base equipment Roller malt mill 150 kg/hRM-1501 pcs.990,00 Two-units brewhouse for 300 litersBH-3001 pcs.11100,00 CCT at 600 litersCCT-6007 pcs.3700,0025900,00 Plate sanitary wort chiller for wort cooling HE-300HE-3001 pcs.1110,00 CIP-station for tanks up to 600 liters and beer kegsCIP60(2)K1 pcs.3070,00 Beer Glycol Chiller for Fermentation Tanks Cooling CH-6CH-61 pcs.5610,00 Cost of base equipment:47780,00 € Additional equipment Hot water tank at 600 litersHWT-6001 pcs.3250,00 Cold water tank at 600 litersCWT-6001 pcs.3700,00 Cost of additional eqiupment:6950,00 € Cost of complete set:54730,00 € Electricity consumers: Roller malt mill – 1.5 kWt Two-units brewhouse – 23 kWt CIP-station – 3.8 kWt Beer Glycol Chiller – 3 kWt Hot water tank – 5 kWt

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

UTF

Ukraine

Capacity: 150-500 kg/h Thickness of product: 1,1-1,8 mm Raw material: flour, semolina, corn flour, bean flour and ect. Energy source for oven: electricity Energy source for fryer: electricity, thermos oil, Key features of the production line: - automatic batching system of raw materials is foreseen - different recipe and color of product - homogeneity of batch - different tastes with different spices - design of lines can be developed according to customer’s production premises Equipment set of the line: - extruder of dough ribbon with distributor - dough rolling machine - stretching device - conveyor with knife mechanism - tunnel oven - cooling conveyor - slicing machine - feeding conveyor - drum for removing crumb and small fraction - fryer - conveyor for oil removal - drum with spices batcher - cooling conveyor - elevator - packing machine

Request for a quote

UTF

Ukraine

Capacity: 250-2000 kg/h Thickness of product: 0,9-1,1 mm Raw materials: flour, semolina Energy source: liquid fuel, solid fuel, electricity, gas Control system is carried out with controller and TOUCHSCREEN Key features of the production line: - apart of short cut pasta it is possible to produce potato pellets on the same line - automatic batching system of raw materials is foreseen - machinery provides homogeneity of mixing of components - high quality of the product due to mixing and pressing is made in vacuum conditions - press is completely automatic - flexible system for the adjustment of product dimensions is foreseen - humidity and temperature in the dryer are maintained automatically - different recipe can be use - design of lines can be developed according to customer’s production premises Equipment set of the line: - bag tilting device - flour sifter-batcher - press - trabatto - elevator - drying chamber - cooling chamber - elevator - storage hoppers

Request for a quoteResults for

Industrial equipment - Import exportNumber of results

8 ProductsCountries

Company type