- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- machinery and equipment

Results for

Machinery and equipment - Import export

KIEVGUMA

Ukraine

Product usage: To improve the efficiency of sowing grain crops, cleaning grain and sieve grain cleaning machines. Specifications: Balls for threshing grain crops made of a specially developed high-quality oil-resistant rubber compound. Balls for threshing grain have the increased spring property. We produce balls of 2 diameter types: 34 mm, 38 mm. Packing: Individual packaging: polymer package.

Request for a quote

KIEVGUMA

Ukraine

Product usage: To complete equipment procurement for plucking domestic and wild birds in the food processing industry. Specifications: Plucking fingers made of high-quality wear-resistant rubber. Presence of ridge ribs on the surface of plucking fingers provides better removal of large and hard feathers of birds. Depending on the category of birds, plucking fingers made in 2 size types: 1. Length - 90 mm. 2. Length - 145 mm. Shore A hardness: 50 units

Request for a quote

KIEVGUMA

Ukraine

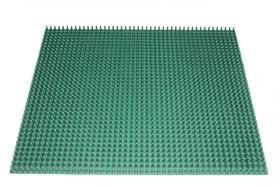

Product usage: They are used for the convenience of laying eggs in poultry, fits into nests and protects eggs from mechanical damage. Benefits: Made from high quality wear resistant rubber compound. Allows you to protect the egg from mechanical damage; prevents bird feathers and down from sticking to the shell; environmentally friendly material of the matting is resistant to moisture, bacteria, mildew and insects,is washed and disinfected perfectly; the rounded ends of the villi are comfortable for chickens; the vertical arrangement of the bristles makes the matting resistant to wear and tear. Specifications: Length - 450 mm; Width - 370 mm; Thickness - 1,6 mm; Height - 18,4 mm. Shore A hardness: 55 to 75 Rubber strength: not less than 24 MPa. Shelf life: 2 years from the date of their manufacture, subject to storage rules. Production method: Molded

Request for a quote

PACKING TECHNOLOGIES LLC

Ukraine

Voltage, V/Hz – 220/50 Installed power, кW – 2 Pneumatic Supply, atm./ l.m.. – 250/4 Dimensions (not more than), mm – 1200/900/3500 Weight (not more than), kg - 450 Packaging dimensions, mm – 50-150/50-150 Output (max), packs per hour - 2 000

Request for a quote

PACKING TECHNOLOGIES LLC

Ukraine

Power, Wt/Hz – 220/50 Installed capacity, кW – 1,5 Pneumatic Supply, atm./l.m. – 250/4 Dimensions (not more than), mm – 1800/900/1100 Weight ( not more than ), kg - 250 Packaging dimensions, mm – 50-150/50-150 Output (max), packs per hour - 2 000

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

PACKING TECHNOLOGIES LLC

Ukraine

Voltage, V/Hz – 380/50 Installed power, кW – 2,5 Pneumatic Supply, atm./ l.m.– 4/250 Dimensions (not more than), mm – 1600/1100/1200 Weight (not more than), kg - 320 Packaging dimensions, mm – 80-390/80-240 Output (max), packs per hour - 3 000

Request for a quote

PACKING TECHNOLOGIES LLC

Ukraine

Voltage, V/Hz – 380/50 Installed power, кW – 2,5 Pneumatic Supply, atm./ l.m.– none Dimensions (not more than), mm – 1500/1100/1200 Weight (not more than), kg - 300 Packaging dimensions, mm – 80-290/80-190 Output (max), packs per hour - 2 700

Request for a quote

BROVARNI

Ukraine

Cost of equipment: Base equipment Two-units brewhouse for 1000 litersBH-10001 pcs.22800,00 Roller malt mill 300 kg/hRM-3001 pcs.1340,00 Plate sanitary wort chiller for wort cooling HE-1000HE-10001 pcs.1680,00 CIP-station for tanks up to 1000 liters and beer kegsCIP100(2)-K1 pcs.3900,00 Beer Glycol Chiller for Fermentation Tanks Cooling CH-12CH-121 pcs.7860,00 Cost of base equipment:71880,00 € Additional equipment Hot water tank at 2000 litersHWT-20001 pcs.6100,00 Cold water tank at 2000 litersCWT-20001 pcs.6800,00 Cost of additional eqiupment:12900,00 € Cost of complete set:84780,00 € Electricity consumers: Two-units brewhouse – 64 kWt Roller malt mill – 1.5 kWt CIP-station – 6.1 kWt Beer Glycol Chiller – 4.5 kWt Hot water tank – 13 kWt

Request for a quote

BROVARNI

Ukraine

Cost of equipment: Base equipment Roller malt mill 150 kg/hRM-1501 pcs.990,00 Two-units brewhouse for 300 litersBH-3001 pcs.11100,00 CCT at 600 litersCCT-6007 pcs.3700,0025900,00 Plate sanitary wort chiller for wort cooling HE-300HE-3001 pcs.1110,00 CIP-station for tanks up to 600 liters and beer kegsCIP60(2)K1 pcs.3070,00 Beer Glycol Chiller for Fermentation Tanks Cooling CH-6CH-61 pcs.5610,00 Cost of base equipment:47780,00 € Additional equipment Hot water tank at 600 litersHWT-6001 pcs.3250,00 Cold water tank at 600 litersCWT-6001 pcs.3700,00 Cost of additional eqiupment:6950,00 € Cost of complete set:54730,00 € Electricity consumers: Roller malt mill – 1.5 kWt Two-units brewhouse – 23 kWt CIP-station – 3.8 kWt Beer Glycol Chiller – 3 kWt Hot water tank – 5 kWt

Request for a quote

BROVARNI

Ukraine

Cost of equipment: Base equipment Roller malt mill 150 kg/hRM-150 Two-units brewhouse for 300 litersBH-300 CCT at 300 litersCCT-300 Plate sanitary wort chiller for wort cooling HE-300HE-300. CIP-station for tanks up to 600 liters and beer kegsCIP60(2)K Beer Glycol Chiller for Fermentation Tanks Cooling CH-6CH-6 Cost of base equipment:41830,00 € Additional equipment Hot water tank at 600 litersHWT-600 Cold water tank at 600 litersCWT-600 Cost of additional eqiupment:6950,00 € Cost of complete set:48780,00 € Electricity consumers: Roller malt mill – 1.5 kWt Two-units brewhouse – 23 kWt CIP-station – 3.8 kWt Beer Glycol Chiller – 3 kWt Hot water tank – 5 kWt

Request for a quote

UTF

Ukraine

Capacity: 1800 - 4200 pcs/h Number of rows: 3-7 Energy source: electricity Key features of the production line: - compact design - ability to work as part of a line or separately - replaceable cutting drums for different sizes of croissants

Request for a quote

UTF

Ukraine

Capacity: 100-500 kg/h Energy source: electricity Control system is carried out with controller and TOUCHSCREEN Key features of the production line: - the length of production line depends on product range from 4.5m up to 10.0m - wide range of products due to replaceable units: feeding of liquid fillings sprinkling with sugar, poppy seeds, sesame, etc. twisting in a roll one- and multiple folding surface cuts Equipment set of the line: - forming table - calibrator - cutting unit - a sprinkler of loose ingredients with a humidifier and pressure roller - depositor of liquid filling - folding nodes - guillotine

Request for a quote

UTF

Ukraine

Capacity: 300-1200 kg/h Quantity of dough layers: 8-16 Raw materials: flour Energy source: electricity Control system is carried out with controller and TOUCHSCREEN Key features of the production line: - proofing of product at proofing chamber for improving quality of products - replaceable drums of forming machine for different kinds and sizes of product - options for additional equipment: automatic dough feeding system into extruder salt sprinkler at the oven entry oil sprinkling on the exit form the oven stackers for staking products in stacks - design of lines can be developed according to customer production premises Equipment set of the line: - dough kneading device - proofing chamber - feeding conveyor - extruder - laminator - three-modular rolling machine - forming machine - tunnel oven - rotary conveyor - cooling conveyor - stacker

Request for a quote

UTF

Ukraine

Capacity: 100-500 kg/h Quantity of dough layers: up to 288 Raw materials: flour Energy source: electricity Control system is carried out with controller and TOUCHSCREEN Key features of the production line: - equipment set of the production line depends on required quantity of layers - automatic batching of components - multiple rolling of the dough creates an ideal layered structure with a uniform distribution of the fat layer between the layers - comfortable access to the units and mechanisms which is contacting with dough, for maintenance and cleaning - production line can be designed according customer’s production premises Equipment set of the line: - dough ribbon extruder - calibrator (2 pcs.) - extruder of fat - rolling unit (2 pcs.) - multiroller (4 pcs.) - laminator (2 pcs.)

Request for a quote

UTF

Ukraine

Capacity: 100-500 kg/h Quantity of dough layers: up to 288 Raw materials: flour Energy source: electricity Control system is carried out with controller and TOUCHSCREEN Key features of the production line: - automatic batching system of raw materials is foreseen - wide varaity of products provided by replacable units of forming machine: feeding liquid filling sprinkling by sugar, sesame, poppy rolling in a roll one- and multiple rolling notching on surface - design of lines can be developed according to customer’s production premises Equipment set of the line: - lamination line with fat extruder - forming line - tunnel oven - conveyors system for cooling and packing

Request for a quoteResults for

Machinery and equipment - Import exportNumber of results

16 ProductsCountries

Company type