- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- wet painting booths

Results for

Wet painting booths - Import export

ROTA MACHINERY MANUFACTURING CONTRACTING

Turkey

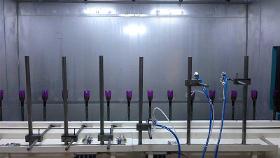

The main part of the wet painting lines that we have produced is wet painting booths. Wet painting booths are used to apply wet paint on the material under the most ideal conditions after the surface cleaning process and to prevent the paint that can not hold onto the work piece from being escaped to the environment. The wet paint is atomized by high pressure air and applied on the part that is going to be painted. It is preferred because it is easy to apply and gives good results. As Rota Makine, we design lines with conveyor and robots to offer our esteemed customers who want to make production with high capacity, automation and untouched. Our wet painting booths are categorized as With Water Curtain and With Solid Filter because of their different advantages. Wet enameling cabinets for enamel applications are also available in our scope of production.

Request for a quote

ROTA MACHINERY MANUFACTURING CONTRACTING

Turkey

Our wet painting booths are manufactured as standard or custom design according to the customer’s needs. For the cabin selection, the dimensions of the parts and the targeted capacity are the determining elements. Our booths are made of stainless steel or galvanized sheet and fully assembled with bolts. In our wet painting booth with water curtain, the air is sucked through the water curtain by exhaust fans while the unused wet paint is held by water. And the clean and healthy environment is created by supplying the fresh air to the environment. Teflon (non-stick), solvent based and water based paint applications can be applied in our wet painting booths. We also design Flash off and Positive Pressure rooms for our wet paint plants. In flash off rooms, solvent separation process of painted parts is done. The solvent that released in these rooms is removed by exhaust fans and a healthy working environment is obtained.

Request for a quote

ROTA MACHINERY MANUFACTURING CONTRACTING

Turkey

Our wet painting booths are manufactured as standard or custom design according to the customer’s needs. For the cabin selection, the dimensions of the parts and the targeted capacity are the determining elements. Our booths are made of stainless steel or galvanized sheet and fully assembled with bolts. In our wet painting booth with solid filter, the air is sucked through the filters by exhaust fans while the unused wet paint is held by paper or fiber filters. And the clean and healthy environment is created by supplying the fresh air to the environment. Teflon (non-stick), solvent based and water based paint applications can be applied in our wet painting booths. We also design Flash off and Positive Pressure rooms for our wet paint plants. In flash off rooms, solvent separation process of painted parts is done. The solvent that released in these rooms is removed by exhaust fans and a healthy working environment is obtained.

Request for a quote

PERGEL METAL

Turkey

The paint plant is especially preferred in the construction and furniture industry. The materials used in this sector are painted both for aesthetic purposes and for protection purposes. Paint plants is a far-reaching term. There are varieties. Its quality and form vary. In general, the age paint plant is more preferable. There is a wet paint booth, conveyor system and drying oven in the paint plant. It is produced in accordance with the most suitable conditions and made suitable for use.

Request for a quote

VOGAMAKINA INDUSTRIAL PLANTS LTD. CO.

Turkey

Combined spraybooths are designed for manual painting application for automotive industry with downdraft ventilation and drying system. It is manufactured from insulated panel body. Installed to the factory ground or to an metal basement, extraction air ducts are placed at the ground, Fresh air plenum and filtering system is located at the ceiling that creates clean environment inside the spray booth during the painting and drying application. Painting or drying option are selected manually from the control panel, flash-off and cooling positions are automatically controlled. Includes standard type illumination system and optionally Ex-zone, electrical control panel and wiring to the control panel is done. The spray booth is fully controlled by PLC control system and a touch panel. Control system indicates when filters gets contamnated. Filters are easy replaceable. The spraybooth is CE certificated and conforms to the European Norms.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ENDUSTRI GM

Turkey

In order to achieve the desired quality in wet paint application, the main standards that must be fulfilled in the facilities are appropriate filtering and clean air system, suitable air conditioning and appropriate lighting. The electrical equipment in the painting facility must be suitable for the explosion document. Filtration systems must comply with the regulations of the Ministry of Environment waste gas emission values.

Request for a quoteResults for

Wet painting booths - Import exportNumber of results

7 ProductsCountries

Company type