- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- system pallets

Results for

System pallets - Import export

NOVOSIM

Turkey

A Pallet Stacking Machine automates the process of palletizing goods, enhancing efficiency in warehouse operations. This machine is designed to stack products onto pallets systematically and securely, minimizing manual labor and optimizing space utilization. Equipped with advanced robotics and conveyor systems, the Pallet Stacking Machine offers high-speed and precision palletization capabilities. It ensures uniform stacking patterns and proper weight distribution for safe transportation and storage of goods. The machine's intuitive control interface allows for easy programming and adjustment of stacking parameters. It can handle a variety of product sizes, shapes, and weights, making it versatile for diverse manufacturing and distribution environments.

Request for a quote

PARSMEGA MAKINA

Turkey

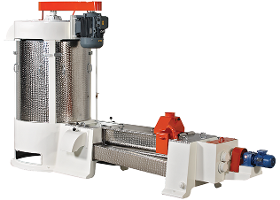

It cleans the stone, soil, all dust particles and bacteria of the wheat with water. It has a double seal device that prevents oil and water from mixing. The entry point of the wheat into the washing tub is moved back and forth to adjust the time the wheat stays in the water. The upper screw rotates rapidly and agitates the water, performing the washing process. Foreign materials (stones, etc.) heavier than wheat sink to the bottom and are thrown out by the gizzard screw rotating in the opposite direction. Light substances such as dust, straw and garbage in the wheat are collected on the surface of the water and thrown out with water through the husk hole. The wheat dragged by the upper screw goes to the vertical drying section working with the centrifugal system. Rapidly rotating pallets in vertical drying throw the product towards

Request for a quote

ILK IHRACAT AS.

Turkey

For companies seeking the ultimate in automation and efficiency, fully automated loading and unloading systems are the answer. These systems utilize advanced technology, such as robotics and computerized controls, to handle the entire loading and unloading process without human intervention. Goods are automatically sorted, transported, and loaded onto trucks, eliminating the need for manual labor entirely. Fully automated systems are ideal for high-volume operations where speed, accuracy, and consistency are paramount. In conclusion, automatic loading and unloading systems offer numerous benefits for companies in the transportation industry. Whether it’s conveyor systems, hydraulic lift gates, pallet jacks, or fully automated systems, these technologies enhance productivity, improve safety, and streamline operations. By implementing these systems, companies can reduce labor costs, minimize the risk of injuries, and increase overall efficiency.

Request for a quote

NOVOSIM

Turkey

A Pallet Stacking Machine automates the process of palletizing goods, enhancing efficiency in warehouse operations. This machine is designed to stack products onto pallets systematically and securely, minimizing manual labor and optimizing space utilization. Equipped with advanced robotics and conveyor systems, the Pallet Stacking Machine offers high-speed and precision palletization capabilities. It ensures uniform stacking patterns and proper weight distribution for safe transportation and storage of goods. The machine's intuitive control interface allows for easy programming and adjustment of stacking parameters. It can handle a variety of product sizes, shapes, and weights, making it versatile for diverse manufacturing and distribution environments.

Request for a quote

NOVOSIM

Turkey

A Pallet Stacking Machine automates the process of palletizing goods, enhancing efficiency in warehouse operations. This machine is designed to stack products onto pallets systematically and securely, minimizing manual labor and optimizing space utilization. Equipped with advanced robotics and conveyor systems, the Pallet Stacking Machine offers high-speed and precision palletization capabilities. It ensures uniform stacking patterns and proper weight distribution for safe transportation and storage of goods. The machine's intuitive control interface allows for easy programming and adjustment of stacking parameters. It can handle a variety of product sizes, shapes, a

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

NOVOSIM

Turkey

A Pallet Stacking Machine/ Pallet Rack Machine automates the process of palletizing goods, enhancing efficiency in warehouse operations. This machine is designed to stack products onto pallets systematically and securely, minimizing manual labor and optimizing space utilization. Equipped with advanced robotics and conveyor systems, the Pallet Stacking Machine offers high-speed and precision palletization capabilities. It ensures uniform stacking patterns and proper weight distribution for safe transportation and storage of goods. The machine's intuitive control interface allows for easy programming and adjustment of stacking parameters. It can handle a variety of product sizes, shapes, and weights, making it versatile for diverse manufacturing and distribution environments.

Request for a quote

OM GLOBAL TRADE CO. LTD.

Turkey

As the distributor of MAXXRACK™, we offer warehousing solutions. MAXXRACK™ is a versatile warehouse storage solution made from high-quality galvanized iron with a high load capacity of an extra 3200 kg. Without having to leave the vehicle, the forklift driver can pick a rack from the storage and easily place it on a pallet location. Its ingenious construction makes the MAXXRACK™ compact to stack and therefore easy to transport. Storage capacity is increased by 90% thus also increasing the efficiency of your warehouse.

Request for a quote

BEYAZLI GROUP

Turkey

Concrete Mix Plant - Hollow Block Making Machine - Paving Block Making Machine - Curbstone Making Machine Ready mix concrete plant - Concrete block machine - Paving block machine - Interlock bricks machine - Cinder block making machine - Hollow block machine - concrete block making machine - paving block making machine - interlock brick making machine Campaign Code : C-001 Campaign Price : 52.367 EURO (free installation and free staff training) Contact: Seher +90 5326382935 (Whatsapp Now) Warranty: minimum 24 months Capacity: (8 HOURS) 5.000 Pieces 20 Cm Of Hollow Blocks - 15 m3 / Hour Ready Mix Concrete Transportation : (WITHOUT THE PALLETS ) Max. 1 HQ 40' Container With Single Mortar Hopper - Semi Automatic System - Manual Pallet Carrying System - Fully Automatic Mortar System (Without Hopper And Cement Silos) - Daily Capacity 5.000 Pieces 20 Cm Of Hollow Blocks - 15 m3 / Hour Ready Mix Concrete - Max.

Request for a quote

BEYAZLI GROUP

Turkey

Campaign Price: 12.685 EURO (free installation and free staff training) Contact: Seher +90 5326382935 (Whatsapp) Warranty: minimum 24 months Capacity: 2250 Concrete Blocks 20 cm width /8 HOURS Transportation : 1 HQ 20' Containers With Single Mortar Hopper - Semi-Automatic or Full Automatic System - Manual Pallet Carrying System - Fully Automatic Mortar System (With Hopper And Cement Silos) - Daily Capacity 2.500 Hollow Blocks of 20 Cm - 1000 m2 Construction Area - Totally Needs 4 kW Energy - It Is An Ideal Machine That Can Be Able To Produce With Max. 4 Persons - Designed To Work 24 Hours. Through Special Vibro Motors Machine Can Produce Every Stone Which Heigh Between 18 / 25 Cm. Video of machine: https://www.youtube.com/watch?v=VQ_2iQm_C0U&t=5s concrete block machine - Hollow block machine - bricks machine - Cinder block machine - Hollow brick machine - Concrete batching plant Optionally

Request for a quote

GYPSUM TECHNOLOGY

Turkey

Automatic Palletizing Units. Automatic palletizing units will allow you to speed up your production process. Thanks to our machine, your stacked pallets will allow you to use your stock space more efficiently, and your factory will be more organized. This arrangement will contribute to the performance of your employees in the factory and will allow you to load and ship your products in a shorter time and easily. Automatic palletizing units will contribute to the increase of production capacity by preventing losses due to labor as well as profit from the labor cost. Areas of use and specifications of the system. -Automatic palletizing systems can be used in facilities where PP bags, PE bags or Kraft bags are used. •Stacks 0-50 kg bags on pallets •Stacks bags of sizes 500 x 750 x 150 mm and 260 x 320 x 100 mm or similar dimensions •Can caryy pallets of weight 0-2000 kg •Stacks pallets of differen size and quantities, e.g.

Request for a quote

GLOBMAC GLOBAL BLOCK MACHINES

Turkey

This machine is designed to produce inter locks , blocks. insulated blocks, curbstone it can produce 140-150 pallet per hour 25 interlocks pcs/1 press 10 blocks pcs / 1 press press time is 25-30 seconed it has two system: full automatic and semi automatic it can be use with stacking system or with out stacked pallet must be transport with forklift for machine with stacking system. machine works on the wooden pallet there are two types of mortar reading system. It is manual and automatic weighing system cement water and sand weighn and mortar are mixed all motions on the machine provided by hydraulic system movements on the system will be controlled by PLC automation system via sensors in automaticmachine, machine press number unit of productions , problems on the machine can be seen on the PLC touchscreen panel.

Request for a quoteResults for

System pallets - Import exportNumber of results

12 ProductsCountries

Company type