- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- spray paint booth

Results for

Spray paint booth - Import export

VOGAMAKINA INDUSTRIAL PLANTS LTD. CO.

Turkey

Combined spraybooths are designed for manual painting application for automotive industry with downdraft ventilation and drying system. It is manufactured from insulated panel body. Installed to the factory ground or to an metal basement, extraction air ducts are placed at the ground, Fresh air plenum and filtering system is located at the ceiling that creates clean environment inside the spray booth during the painting and drying application. Painting or drying option are selected manually from the control panel, flash-off and cooling positions are automatically controlled. Includes standard type illumination system and optionally Ex-zone, electrical control panel and wiring to the control panel is done. The spray booth is fully controlled by PLC control system and a touch panel. Control system indicates when filters gets contamnated. Filters are easy replaceable. The spraybooth is CE certificated and conforms to the European Norms.

Request for a quote

ENDUSTRI GM

Turkey

In order to achieve the desired quality in wet paint application, the main standards that must be fulfilled in the facilities are appropriate filtering and clean air system, suitable air conditioning and appropriate lighting. The electrical equipment in the painting facility must be suitable for the explosion document. Filtration systems must comply with the regulations of the Ministry of Environment waste gas emission values.

Request for a quote

ROTA MACHINERY MANUFACTURING CONTRACTING

Turkey

Our wet painting booths are manufactured as standard or custom design according to the customer’s needs. For the cabin selection, the dimensions of the parts and the targeted capacity are the determining elements. Our booths are made of stainless steel or galvanized sheet and fully assembled with bolts. In our wet painting booth with water curtain, the air is sucked through the water curtain by exhaust fans while the unused wet paint is held by water. And the clean and healthy environment is created by supplying the fresh air to the environment. Teflon (non-stick), solvent based and water based paint applications can be applied in our wet painting booths. We also design Flash off and Positive Pressure rooms for our wet paint plants. In flash off rooms, solvent separation process of painted parts is done. The solvent that released in these rooms is removed by exhaust fans and a healthy working environment is obtained.

Request for a quote

ROTA MACHINERY MANUFACTURING CONTRACTING

Turkey

Our powder paint booths are manufactured as standard or custom design according to the customer’s needs. For the cabin selection, the dimensions of the parts and the targeted capacity are the determining elements. Our booths are made of stainless steel or galvanized sheet and fully assembled with bolts to easy disassembling. Recycling is done with the cyclones in our powder coating booths with cyclone. It is preferred because it allows easy and fast color change. The powder particles which are not used passes through the cyclone unit before the filter unit. While the particles go down through cyclones with centrifugal effect, the particle that cannot be reused is sent to the filter unit and filtered there. The parts which are suitable for recycling are recycled to the system for reuse. Multi and mono type cyclone units are used in our booths. Both types offer efficiency with recycling systems, practicality with easy color changing. In filter cabins, it is necessary to change

Request for a quote

ROTA MACHINERY MANUFACTURING CONTRACTING

Turkey

Our powder paint booths are manufactured as standard or custom design according to the customer’s needs. For the cabin selection, the dimensions of the parts and the targeted capacity are the determining elements. Our booths are made of stainless steel or galvanized sheet and fully assembled with bolts to easy disassembling. In our powder paint booths with filter, the air is sucked through the filters while the unused powder particles are held by filters. The filters are automatically and periodically pumped air in reverse direction to direct the powder paint that held by filters to the sieve tanks which is under the cabinet for reusing. As a result of this process, the unused powder paint is recycled. Polyester-Teflon and Sinter-Lamellar type filters are used in our booths. Polyester-Teflon filters are preferred due to their low cost and Sinter-Lamellar filters are preferred due to their long filter life. Both types offer efficiency with recycling systems, economical solution

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

SEGA GROUP OF COMPANIES

Turkey

Preparation is always the key to a successful project, take your time to clean, treat any rust, rub down and mask the area. You will need to purchase a grey primer and apply at least two coats of the primer to ensure optimum adhesion and to give the best finish. When you are ready to apply the paint, build up the colour with several thin coats, rubbing down with wet and dry sandpaper in between coats to ensure a professional finish. For metallic and pearlescent colours it is essential to purchase a lacquer, which will give a high gloss finish to solid colours.

Request for a quote

YILDIZ CILA POLISHING COMPOUND AND BUFF MANUFACTURER

Turkey

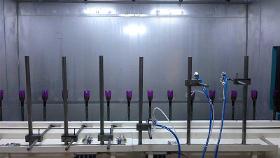

Automatic guns are crucial for automating polishing, painting and coating operations. YILDIZCILA's automatic guns are primarily utilized for mass production, minimizing downtime and maintenance, alongside efficiency and top-notch quality, are key factors. Furthermore, the extensive variety of nozzles allows for personalized adjustments and scaling."

Request for a quoteResults for

Spray paint booth - Import exportNumber of results

8 ProductsCountries

Company type