- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- reinforced concrete

Results for

Reinforced concrete - Import export

KALSEDON STONE

Turkey

SIMPLE APPLICATION, KALSEDON STONE PANEL PREFERED TO MAKE YOUR SPACES BEAUTIFULL WITH SPECIAL DESIGN

Request for a quote

ROBINSON CO.

Turkey

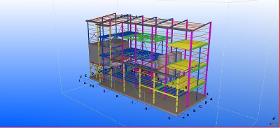

There are several reasons why steel structures are preferred over reinforced concrete structures. The main reasons are fast generation and seismic resistance. Steel structure reduces loss of life and property during disasters and ensures safety. Metallurgical facilities, industrial buildings, sports facilities, hangars, warehouses - these are structures in which metal structures are often used. Light or heavy steel is preferred depending on the project requirements. Since heavy steel is generally preferred in industrial buildings, its load-bearing capacity is suitable for industrial applications.

Request for a quote

MODULE-T

Turkey

The elements of prefabricated structures (sandwich panels, light steel construction elements, roof elements, stairs and corridors for prefabricated multistory buildings) have been designed and painted in advance at the factory and have been dispatched to the site for mounting. Reinforced concrete flooring is required for prefabricated building. The material for the finishing is also supplied to be mounted at the site electrical equipment, lighting, windows and doors, floor covering, sanitary. According to the Project of the customer, the prewired sandwich panels can be manufactured in the factory prior to dispatch. The walls of prefabricated building Sandwich panel outer and inner walls with a high galvanized steel surface (sandwich panel surface steel thickness between 0.40 mm and 1.20 mm.) The sandwich panels are prepainted at the factory. We offer three different types of insulation rockwool, polyurethane or expanded

Request for a quote

TE-FENCE

Turkey

Standard temporary mobile fence in Ø4.50 mm galvanized wire, Ø48×2 mm galvanized vertical tube, Ø48×2 mmgalvanized horizontal tube. Standard panel dimension of 200 x H200 cm or 200 x H250 cm with a 50×150 mesh. Selfsupporting steel or reinforced concrete feet. We can supply the reinforced concrete blocks at the customer’s specific request. The panels are connected to each other with clips in highly galvanized steel or optionally stainless steel. This fence system is installed quickly and is simplified by its special stackable packaging. It is also possible to add L or Yshaped arms with razor or barbed wire in order to reinforce the security of the temporary areas that need to be protected. Temporary fence application areas Temporary site protection – site fence – site barrier Temporary protection of event areas The advantages of our temporary and mobile fences Quick assembly Simplified packing for transferring from one site to another High security against human intrusions

Request for a quote

TUNA WEIGHING AND ELECTRONIC SYSTEM

Turkey

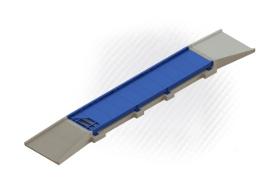

Tuna TS-2 Series vehicle scales have a complete steel platform. It is mounted on the floor, it can be easily climbed onto the scale with reinforced concrete ramps. It is the preferred model produced with "V" beam system. It is modular scale. The scale consists of 6 parts and it is very easy to install and then disassemble and install. The barrier system on the right and left is produced by calculating the maximum strength. In TS-2 series scales, between 4 and 10 units, each with a capacity of 30 tons, according to OIML R60 standards, C4 class stainless steel CT-30t model domestic production load cells are used.

Request for a quote

TUNA WEIGHING AND ELECTRONIC SYSTEM

Turkey

Tuna TS-1 Series vehicle scales have a complete steel platform. They are mounted on the ground and can easily be climbed onto the scale with reinforced concrete ramps. It is the most preferred model. TS-1 series were classical over-floor scales called I beam system. IPE type steel is used on the platform. Top coating hair is 10 mm thick. In TS-1 series scales, between 4 and 10 units, each with a capacity of 30 tons, C4 class stainless steel CT-30t model domestic production load cells are used in OIML R60 standards.

Request for a quote

BMF MEKANIK MUHENDISLIK ITH. IHR. SANAYI VE TIC. LTD STI

Turkey

Product Description Cement based, polymer-reinforced, ready-to-use aerated concrete adhesive mortar with increased adhesion strength and high water absorption. Areas of Usage • lndoor and outdoor, • in vertical and horizontal applications, • Houses, shopping malls, hospitals, • it is used for bonding structural elements such as aerated concrete, bricks. Features and Benefits • Partially resistant against water, damp and frost. • lts application is easy. • it has high adhesion strength. • it saves time and labor.

Request for a quote

ZIM MÜHENDISLIK CONCRETE MACHINES

Turkey

ZIM A 2625 machine is designed to increase efficiency for production of pipes and culverts. It has uniqe specifications to increase production capacity, using life, products quality. This machine can produce pipes 800mm – 2600mm diameter and 2500mm height.Machines can be designed semi or full automatic according to requirements. We use SIEMENS brand PLC microprocessors on automatic machines. The vibration system of machine is controlled by frequency driver controll system. It does not need any mechanic settings. It can easily adjusted from operator pannel. The vibrator system specially designed by our R&D team is used in our machines. The cooling of the vibrators are done by oil cycle system. There is a special unit for that cycling process. Oil flow is controlled by special sensors. Thanks to this technology our machines which have been working for many years without any problems, stand out with their low operating costs.

Request for a quote

BEYAZLI GROUP

Turkey

PRS 400 SEMI AUTOMATIC MACHINE; Semi Automatic System Is Made Like A Mortar Plant. Machine Is Designed To Work 24 Hours. It Has A Different Automation And Capacity System. Machine Is Very Fast And Has High Production Capacity. By Changing The Mould Machine Can Produce Any Types Of Concrete Paving Blocks - Hollow Blocks - Insulated Bricks – Different Curbstones – Asmolen And Chimney Blocks Which Height Must Be Between 5cm And 25 Cm. Equipment List With Prices, Prepared Related To The Installation Layout Is Given Below. Daily Capacity (8 Hours) 4.000 Pieces Concrete Hollow Blocks / 300 M² Paving Blocks… Whatsapp Now: +905326382935 see video below https://www.youtube.com/watch?v=uWEj3G78xwA&t=1s

Request for a quote

ZIM MÜHENDISLIK CONCRETE MACHINES

Turkey

Our ZIM 820 machine is a mid-entry machine designed for the production of double-layer paving stones. The ZIM 820 stands out with its low energy consumption, wide choice of production and high return on investment. It can be used manually, semi-automatically and fully automatically if requested. Our machine, which can produce 8 concrete blocks or 20 concrete paverstones in one press, is designed to produce 1000 pallets per day. To facilitate this production and increase quality; It has many features such as internal shaking system in the mortar cart, driver-controlled vibration system, special balancing system on the upper mold, and a specially designed vibration table. We are using “ FULLDRIVE ” frequency controlled vibration systems in our machine. This helps the life cycle of vibration engines and also decreases the total electrical consumption of vibrators.

Request for a quote

ZIM MÜHENDISLIK CONCRETE MACHINES

Turkey

ZIM 1536 PLUS Block and Paverstone Machine is special design machine for block and interlock production that works fully automatic.The movement of the machine is programmed the PLC microprocessor computer. By changing moulds all kinds of blocks, paverstones, curbstones, grass stones, lentos and precast concrete elements can be produced in a serial way. 20cm block can be produced 15, interlock paverstones can be produced 36 units in one press. Machine is able to produce the insulated block upon demand. Thanks to special features developed by our engineers machine have very short cycle time. For example mould changing is wery easy and take short tme in new system. Automation system and operator panel which is developed and redesigned in long years become user friendly and useful. With our special design vibration table you can produce high quality products with less energy. We use pneumatic bellows in machine mould connections.

Request for a quote

ZIM MÜHENDISLIK CONCRETE MACHINES

Turkey

ZIM 1536 machine is a high-end machine designed for the production of concrete blocks, concrete paverstones and concrete curbstones. ZIM 1536 comes out with high-end hardware, wide options of production and low labor cost. It can be used in automatic facilities such as FINGER CAR, BASKET SYSTEM, L TYPE SYSTEM. Our machine that can produce 15 blocks or 36 paverstones in one press, is designed to produce 1200-1400 pallets per day. Aiming at maximum capacity with mass production, our machine is designed to work non-stop! Our machine, which can follow the mortar in machine with the loadcell system in the bunkers, takes you to the next level with the proportional mortar car movement, and reaches the maximum quality with the mold balancing and pressing system, is a pioneer in the sector with its many hardwares!

Request for a quote

DEMIRHAN

Turkey

At first,the ground of field is hardened for leveling by steamroller or ground roller. For ground concrete,the place is excavated by JSB or etc. The concrete is poured to the excavated area. 25cmx50 cm molds are placed. The reinforcing bars are placed into the molds. Before pouring the concrete,anchor pipes are put amoung the reinforcing bars.After pouring the concrete,the gravels are poured up to the zero point as No:4 , No:3, No:2 sequintally.76mmx3mm thick h:600 cm verizontal pipes are placed.After placing all pipes,60mmx2mm thick horizontal pipes are welded to the vertical pipes. Vertical and horizontal pipes are painted with anticorrosion paint. Over the anticorrosion paint,RAL 6005 paint is applied. Then the area is enclosed with 50cmx50cm sized 3,50 mm thick PVC wire mesh. 55 mm thick artificial turf is roll outed. Silica sand and sbr granuls is applied into the turf. Sport equipments,goalposts,top covering mesh,lighting projector and projector posts are installed.

Request for a quote

ÖRNEK ELMAS TESTERE SAN. VE TIC. LTD. ŞTI

Turkey

High quality, extreme longevity. Double row of segments. The holes in the core make the grinding cup suitable for machines with dust extraction. Available in 2 types: concrete and brick. For grinding concrete and hard stone materials.

Request for a quote

ÖRNEK ELMAS TESTERE SAN. VE TIC. LTD. ŞTI

Turkey

Our Core drills are manufactured with optimised diamond secment and welded with the latest Laser welding technology

Request for a quote

ÖRNEK ELMAS TESTERE SAN. VE TIC. LTD. ŞTI

Turkey

Laser Welded Saw blade for Concrete both reinforced and normal. Sizes available from 180mm up to 2000mm

Request for a quote

GEOPLAS GEOSYNTHETICS

Turkey

GCL - Bentonite clay liners

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

NAMTAS CONCRETE BLOCK MACHINES AND CONCRETE PRODUCTS

Turkey

YB-1220 represents a new high-tech type of movable egg-laying concrete block machines, produced by Namtas since the beginning of 1980-s. This machine features high throughput and robust easy-to-use design. The machine moves on wheels along straight line on flat even concrete surface according to the specified program while moulding hollow, solid or insulated wall blocks from 185 to 300 mm in height directly on the floor. Delivery of fresh concrete from batching plant to the machine is done by a forklift equipped with a special hopper attachment. YB-1220 does not require production pallets and product handling systems to operate, minimizing customer’s initial financial input and reducing production costs. YB-1220 can be equipped with expanded polystyrene adding unit, allowing it to produce insulated wall blocks.

NAMTAS CONCRETE BLOCK MACHINES AND CONCRETE PRODUCTS

Turkey

Namtas fully automatic batching plants are reliable and time-proven pieces of engineering being able to perform at their best in any conditions. They are designed specifically for the preparation of no-slump concrete mix (dry-mix concrete), which is required for the manufacturing of high-quality concrete products. Namtas batching plants can be installed together with Namtas concrete block machines or integrated into already functioning concrete block production plant.

NAMTAS CONCRETE BLOCK MACHINES AND CONCRETE PRODUCTS

Turkey

NS-20 is the most compact automatic stationary concrete products machine Namtas manufactures. This reliable time-proven machine is made specifically for those investors and entrepreneurs, who want to start the production of the variety of concrete blocks with minimum financial input, while still being able to manufacture high-quality products, such as paving stones, curbstones, hollow and solid masonry blocks, filler blocks, rain gutters and hardscape elements from 60 to 200 mm in height. NS-20 is integrated in Type A concrete block production plants without automatic cuber. This means cured products should be transferred from production pallets to the transport pallets using manual labour.

NAMTAS CONCRETE BLOCK MACHINES AND CONCRETE PRODUCTS

Turkey

NS-30 and NS-25 are single-layer medium-pallet concrete block machines designed to manufacture high-quality concrete products, such as pavers, curbstones, hollow and solid wall blocks (including lightweight and insulated type), rain gutters and hardscape elements from 60 to 300 mm in height. The main difference between the machines is the size of vibration table, which is slightly bigger in NS-30. This increase machine’s production capacity for pavers and curbstones, as well as allows to produce 1 meter long curbstones lengthwise in the standing position. RIGID DURABLE FRAME AND PNEUMATIC MOULD BOX CLAMPING Both machines has a robust heavy-duty frame welded of rectangular steel tubes 150 x 150 mm. Mould and compaction head carriers are mounted on 4 80mm chrome-plated guiding columns. Mould is attached to the mould carrier via 4 airbags while compaction head is attached to the compaction head carrier via bolts.

NAMTAS CONCRETE BLOCK MACHINES AND CONCRETE PRODUCTS

Turkey

Being the best-selling model among all Namtas concrete products machines NS-36 combines durable and reliable design with high throughput and best price/performance ratio. These features contribute to the fast recouping of the capital invested in the machine. Equipped with fast mould changing device, NS-36 is capable of manufacturing a large variety of concrete products, such as paving stones, solid and hollow concrete blocks (including insulated type), filler blocks, curbstones, concrete gutters and hardscape units from 60 to 400 mm in height. HEAVY-DUTY SOLID FRAME Machine frame is a robust heavy-duty structure welded of rectangular steel tubes 150 x 200 mm. Reinforced hard-chromed guiding columns and supporting them linear bearings stabilize the mould and minimize its oscillation.

NAMTAS CONCRETE BLOCK MACHINES AND CONCRETE PRODUCTS

Turkey

Combination of company’s experience and modern technology is embodied in a new high-performance large pallet concrete products machine of NT series – NT-36. This machine represents the crowning achievement of a long and laborious work of Namtas’s engineers in collaboration with The Scientific and Technological Research Council of Turkey. Following years of research and tests this machine was successfully launched into production in 2015. This multi-purpose machine is designed to manufacture a large variety of concrete products including pavers, hollow blocks, filler blocks, curbstones, rain gutters and hardscape elements from 60 to 500 mm in height.

NOVATEC TEKNOLOJI A.S.

Turkey

For over thirty years, we are manufacturing concrete pipe machines, manhole machines, culvert machines, concrete barrier machines with moulds, pallets and all other equipment in our factory. We have full automatic and manuel models for different users in all sizes. We can also offer turnkey plants for the complete set of machinery for pipes, manholes and culverts with the concrete batching plants and gantry cranes.

Request for a quote

BETONSEN

Turkey

Over one pallet 18 pcs blocks 19х39х19. Pressing time 20 second İn one hour 3240 pcs blocks producing. Over one pallet 42 pcs interlocks. Pressing time 28 second İn one hour 5400 pcs interlocks producing.

Request for a quote

PANTHERE

Turkey

Material: 100% Polypropylene Use: CONCRETE Density: 0,90 - 0,92 gr / cm3, 0.91g/cm3 Melting Point: 168 °C Fiber Length: 48 - 54 mm Elastic Modulus: 9 Gpa Tensile Strength: 530 - 580 Mpa Acid, Alkali & Salt Resistance: 95% Strong Place of Origin: Istanbul, Turkey Brand Name: Panthere Model Number: MAFBR1 Diameter: 0.50 mm Exchange Policies: Free exchange for quality issues Application: Concrete Road Product name: Polypropylene Fibre Color: Gray Length: 48 - 54 mm Type: Monofilament Pp Fiber Shape: Beam-like Net Name: Modified PP Synthetic Fiber

Request for a quoteResults for

Reinforced concrete - Import exportNumber of results

27 ProductsCountries

Company type

Category

- Brick-making - machinery and equipment (10)

- Concrete mixers (8)

- Concrete blocks (4)

- Concrete preparing - machinery and equipment (3)

- Concrete constructions (2)

- Concrete, reinforced - drilling and sawing (2)

- Diamond tools (2)

- Weighbridges (2)

- Prefabricated houses (1)

- Building bricks (1)

- Fences and gates (1)

- Football - equipment and goods (1)

- Models for the building industry (1)

- Steel, structural (1)