- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- raw material processing

Results for

Raw material processing - Import export

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

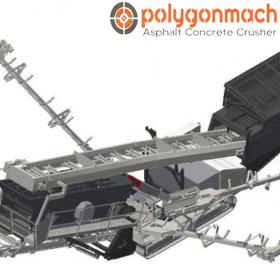

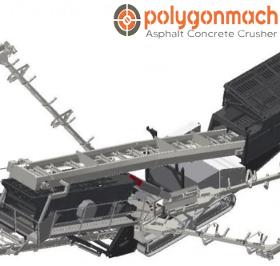

A Mobile Tracked Jaw Crusher is a versatile piece of construction equipment used primarily for the crushing and processing of raw materials in various industries. This equipment is designed with mobility in mind, allowing it to be transported to different job sites with ease. Unlike traditional stationary crushers, mobile tracked jaw crushers are mounted on tracks, which enables them to move around the site and position themselves in optimal locations for efficient material processing. These machines typically feature a jaw crusher mechanism that is used to break down large rocks, stones, and other hard materials into smaller, more manageable sizes. Mobile tracked jaw crushers are widely used in industries such as construction, mining, and recycling. They are essential in the initial stages of material processing, where large chunks of raw material need to be reduced in size before further processing or use.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

A 700 1000 TPH Limestone Crushing and Screening Plant is a facility designed to process limestone raw material into high-quality aggregates with a throughput capacity of 700 to 1000tons per hour. These plants are specifically designed to cater to the demands of different industries like construction, road building, and landscaping, where such high-quality limestone aggregates are required. It usually hosts primary crushing equipment, screening machinery, and conveyors—all designed to handle limestone material conveniently. The initial processing of larger limestone rocks into smaller, more workable fragments is done with primary crushers like jaw crushers and cone crushers. This is very important for the sizing of the raw limestone material, required for further processing, into a size that is ready for making the final product, as per the defined size and quality requirements.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

350-500 tph Riverstone Crushing and Screening Plants are advanced facilities designed to efficiently process Riverstones into high-quality aggregates at a throughput capacity ranging from 350 to 500 tons per hour. These plants consist of specialized primary crushing equipment, screening machinery, and conveyors tailored for the effective processing of Riverstones into various sizes of aggregates suitable for a wide range of construction, landscaping, and industrial applications. The primary crushers, such as jaw crushers or impact crushers, play a crucial role in breaking down the raw Riverstones into smaller fragments at the beginning of the processing cycle. This primary crushing stage is essential for preparing the raw material for subsequent processing stages by effectively reducing the size of the Riverstones within the specified throughput capacity.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

A 40-60 TPH Limestone Crushing and Screening Plant is a facility designed to process limestone raw material into high-quality aggregates with a throughput capacity of 40 to 60 tons per hour. These plants are specifically designed to cater to the demands of different industries like construction, road building, and landscaping, where such high-quality limestone aggregates are required. It usually hosts primary crushing equipment, screening machinery, and conveyors—all designed to handle limestone material conveniently. The initial processing of larger limestone rocks into smaller, more workable fragments is done with primary crushers like jaw crushers and cone crushers. This is very important for the sizing of the raw limestone material, required for further processing, into a size that is ready for making the final product, as per the defined size and quality requirements.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

700-1000 tph Riverstone Crushing and Screening Plants are sophisticated facilities designed to process large quantities of Riverstones into high-quality aggregates at an impressive throughput capacity ranging from 700 to 1000 tons per hour. These plants consist of specialized primary crushing equipment, advanced screening machinery, and efficient conveyors tailored to handle substantial volumes of Riverstones. The primary crushers, such as jaw crushers and impact crushers, play a pivotal role in breaking down the raw Riverstones into smaller fragments at the initial stage of the processing cycle. This primary crushing phase is essential for preparing the raw material for subsequent processing stages by effectively reducing the size of the Riverstones within the specified high throughput capacity range.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

Mobile crushing and screening plants 250-350 tph RS represent a highly technological, skilfully designed material processing equipment aimed at producing high-quality end-aggregates for different levels of Riverstone crushing. These plants integrate special primary crushing equipment, screening machinery, and conveyors for the proper processing of Riverstones into aggregates of different sizes, used in a variety of construction, landscaping, and industrial applications. On the first stage of processing, primary crushers—jaw crushers or impact crushers—are used; at the start of the processing cycle, raw Riverstones get broken down into small shreds. This primary crushing stage is designed to be necessary for the reduction of the size of Riverstones raw material, preparatively for further processing stages. After primary crushing, it is fed into screening equipment—generally, vibrating screens—which sorts the aggregate into various fractions classified based on their sizes.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

A Mobile Tracked Jaw Crusher is a versatile piece of construction equipment used primarily for the crushing and processing of raw materials in various industries. This equipment is designed with mobility in mind, allowing it to be transported to different job sites with ease. Unlike traditional stationary crushers, mobile tracked jaw crushers are mounted on tracks, which enables them to move around the site and position themselves in optimal locations for efficient material processing. These machines typically feature a jaw crusher mechanism that is used to break down large rocks, stones, and other hard materials into smaller, more manageable sizes. Mobile tracked jaw crushers are widely used in industries such as construction, mining, and recycling. They are essential in the initial stages of material processing, where large chunks of raw material need to be reduced in size before further processing or use.

Request for a quote

BASAL TECHNICAL TEXTILES

Turkey

Natural and synthetic fiber raw materials are used for production process in our company’s new and advanced technology production lines. BASAL’s priority in Spunlace nonwoven fabric production is to always maintain the most hygienic conditions. Two different spunlace technology is available : Parallel-lapped line and Cross-lapped line. Our Spunlace product weight ranges for parallel technology is between 25 gr/m²-150 gr/m² and up to 320 cm width and for cross-laped technology is between 45 gr/m²-200 gr/m² and up to 320 cm width Customised production in different color and width combinations with different properties such as particle-free feature, liquid repellency, liquid absorbency, softness, hardness, flexibility, etc is available to meet customer needs. Areas of Used: Medical: Spunlace is used in the production of band-aids, gauzes, bandages, gowns, wiping, and drying cloths. Cleaning and Wiping Cloths: Spunlace is used in the production of cleaning

Request for a quote

SCENTWIND

Turkey

The raw material for obtaining lavender essential oil is inflorescence with a peduncle no longer than 10 cm. We cut them during the period of mass flowering 10-12 days after the beginning of flowering. We cut them off in calm and dry weather, since in the rain and during a strong wind the oil yield decreases sharply. We process raw materials immediately after harvesting fresh. Essential oil is obtained by hydrodistillation, that is, distilled with water vapor. The health benefits of lavender essential oil are its ability to eliminate nervous tension, relieve pain, disinfect skin, improve blood circulation and treat respiratory diseases. Also lavender essential oil is used in the manufacture of perfumes and many aromatic preparations and their combinations. You can buy lavender oil directly from producer. We sell lavander oil, which is directly produced by Scentwind.

Request for a quote

ALPER MAKINA CHOCOLATE PRODUCTION LINES

Turkey

Ball-Mill Ball-mill is batch type refiner for processing cream, natural and palm based chocolates and similar products. Ball mill tank is double jacketed and heated by electrical resistances. Inner and outer jacket , agitators and balls are stainless steel. System also includes thermostatically controlled heating system . The chocolate pump which is used for circulation is also used for discharging. Process time is depends on raw material fineness . Process takes approximately 2½ hours.

Request for a quote

ARESA KIMYA FLAVOUR AND FRAGRANCE

Turkey

The design of the scents that make the product more desirable and increase the brand value with the pleasant emotions awakened in users, beyond making the product it contains smell beautiful, is a process of passion for Aresa Flavor & Fragrance. In this process, all raw materials are carefully selected and combined to form the most unique composition.

Request for a quoteResults for

Raw material processing - Import exportNumber of results

12 ProductsCountries

Company type