- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- pneumatic system

Results for

Pneumatic system - Import export

ROBINSON CO.

Turkey

It is used to discharge or cut the flow of free flowing raw material or product to the desired terminal. It is used to discharge the product transported by the spiral using under the spiral to the appropriate parts. Reciprocating motion is performed by pneumatic piston or manually. The spiral is manufactured in different models according to the chain conveyor model. Two different models (pneumatic and manual) can be used at the outlets of silo and bunker with screw and chain conveyors. Applications Fields ◾ Food industry ◾ Flour and semolina mills ◾ Feed mills ◾ Grain cleaning plants ◾ Corn processing plants ◾ Grain warehouses and silos ◾ Malt Factories

Request for a quote

ROBINSON CO.

Turkey

It is used to transport the products pneumatically to different points over a single line. It allows to change direction during transportation. Applications Fields ◾ Food industry ◾ Flour and semolina mills ◾ Feed mills ◾ Grain cleaning plants ◾ Corn processing plants ◾ Grain warehouses and silos ◾ Malt Factories

Request for a quote

ROBINSON CO.

Turkey

It is the system that allows the crushed goods to be transported by suction. It has the highest efficiency, minimum energy consumption and it is versatile and silent. The fan, mounted on the chassis with a steel cage, works on rubber feet (wedges) in order to prevent vibration and vibration. Since its static and dynamic balance is taken, the noise level is minimized, the inlet and outlet pipes are supported with rubber flanges to prevent vibration transfer. Applications Fields ◾ Food Industry ◾ Flour and Semolina mills ◾ Feed mills ◾ Grain cleaning plants ◾ Corn processing plants ◾ Oil factories ◾ Wheat, barley, rye oats operating facilities

Request for a quote

PARSMEGA MAKINA

Turkey

Pneumatic Cyclone Group is a system that moves the spilled product with air flow. The transportation process is carried out in pipes and the transported materials are sent to the Pneumatic Cyclone. Cyclones are made of sheet steel construction. It has a cylindrical-conical body and consists of an inlet and outlet pipe. It is designed to keep the air loss of the system to a minimum during the separation of air and product in the pneumatic system.

Request for a quote

PARSMEGA MAKINA

Turkey

In pneumatic systems, it is used to separate air and product and to discharge the product inside the cyclones. The product inside the cyclones enters from the cage part of the machine and product passage is provided through the pockets on the rotor.

Request for a quote

PARSMEGA MAKINA

Turkey

Supersonic Filter prevents flour loss from the system by holding the flour particles in the air coming from the fan that carries the function in the pneumatic system, through the felt bags inside its body. It also prevents environmental pollution as it filters the dusty air exhaled. Not only in flour factories; It has a wide usage area in all sectors that perform crushing, crushing and grinding (cement, glass, feed, sugar, etc.).

Request for a quote

ROBINSON CO.

Turkey

The cylindrical body structure is produced in a structure suitable for the product flow in one or both sides, depending on the project conditions, with supporting legs suitable for connecting to the floor deck or floor. The vibro feeding system connected to the conical structure has an adjustable flow flap and is driven by a vibromotor. In flour factories, it is used in the parts that require the adjustment of the ground grains at the appropriate flow and simple feeding, generally in the parts where the filter outlets need to feed a pneumatic line or a machine and where the dust wastes are brought into the system with pneumatics.

Request for a quote

KUZEY GLOBAL

Turkey

CMK 95/65-S4 Station Thermoforming Machine is eligible to form round and rectangular shape lids, plates and trays, single or mu iti compartment containers, hinged lid containers, leaking-proof containers, egg viyole, flower pots and seeding trays. Machine has the bigger forming area than 85 series station machine, and it is better if high is targeted. Machine adopts the latest thermoforming technology itself and intelligent control. This model combines maximum speed and bulk production, high quality and efficiency, and low consumption in energy. lts mould is equipped to perform well with polymer plastics as well as biodegradable plastics. OTHER TECHNICAL SPECIFICATION AII units are fully automatic Movable touch control panel Screen size 15″ and colour Electricity panel assembled to the machine and cooling by AC Ethernet portal Possible to store different mould settings Convenient and fast mould change and pneumatic fixing Pneumatic control systems with servo motors

Request for a quote

KUZEY GLOBAL

Turkey

CMK 95/65-S3 Station Thermoforming Machine is eligible to form round and rectangular shape lids, plates and trays, single or mu iti compartment containers, hinged lid containers, leaking-proof containers, egg viyole, ete. Machine has the bigger forming area than 85 series station machine, and it is better if high capacity is targeted. Machine adopts the latest thermoforming technology itself and intelligent control. This model combines maximum speed and bulk production, high quality and efficiency, and low consumption in energy. lts mould is equipped to perform well with polymer plastics as well as biodegradable plastics. OTHER TECHNICAL SPECIFICATION AII units are fully automatic Movable touch control panel Screen size 15″ and colour Electricity panel assembled to the machine and cooling by AC Ethernet portal Possible to store different mould settings Convenient and fast mould change and pneumatic fixing Pneumatic control systems with servo motors

Request for a quote

KUZEY GLOBAL

Turkey

CMK 85/55-S4 Station Thermoforming Machine is eligible to form round and rectangular shape lids, plates and trays, single or multi compartment containers, hinged lid containers, leaking-proof containers, hole-punch containers, egg viyole, flower pots and seeding trays. Machine adopts the latest thermoforming technology itself and intelligent control. This model combines maximum speed and bulk production, high quality and efficiency, and low consumption in energy. lts mould is equipped to perform well with polymer plastics as well as biodegradable plastics. OTHER TECHNICAL SPECIFICATION AII units are fully automatic Movable touch control panel Screen size 15″ and colour Electricity panel assembled to the machine and cooling by AC Ethernet portal Possible to store different mould settings Convenient and fast mould change and pneumatic fixing Pneumatic control systems with servo motors Automatic lubrication of moveable parts which is activated as perthe specified time space

Request for a quote

ZORLU DEGIRMEN MAKINALARI LTD. STI.

Turkey

The supersonic filter is used for the separation of air-dust mixtures coming from the aspiration system as well as pneumatic conveying systems. The air-dust mixture enters the machine and the dust remains on the filter bags. These filter bags are shaken out using pressurized air by the diaphragm system and the dust is collected at the bottom of the filter. For the removal of the dust collected at the bottom of the machine, a sweeper can be used as well as a conical bottom with a rotoflow.

Request for a quote

ET TAMBURU DONER TEKNIK

Turkey

Chassis: Designed with a focus on strength, durability, and aesthetics. Chassis Material: Entire chassis is made of 304 CrNi material. Height adjustment for rotating attachment tables can be made with a pneumatic system. Equipped with a precise weighing system. Table Dimensions: Width: 850 cm Length: 232 cm Height: 76 cm Warranty: The Horizontal Meat Loading Elevator manufactured by us; (Including manufacturing and fabrication defects) Chassis and boiler construction are guaranteed for 2 years. Electrical components are covered for 1 year under the manufacturers' warranty.

Request for a quote

OMS MEKANIK OTOMASYON SISTEMLERI SANAYI TICARET LIMITED SIRKETI

Turkey

It can fill between 50-500 ml. It can fill between 100-1000 ml It can fill between 250-1500 ml It can fill between 1000-5000 ml The system works with pneumatic 7-8 bar air pressure. System milliliter and weight adjustment are provided by sensors. It makes 750-1500 fillings per hour depending on the consistency of the product. Working voltage is 220 volts 50 Hz. Control voltage is 24 volts. The system works automatically and manually. It is guaranteed for 2 years against factory faults.

Request for a quote

MAKENAS GRAIN MILLING TECHNOLOGY

Turkey

It is used to divert the product both for pressurized conveying and for aspirated pneumatic conveying systems

Request for a quote

MAKENAS GRAIN MILLING TECHNOLOGY

Turkey

It is used to centrifugally separate dust - air mixture and generally is designed as a dust receiver in pneumatic conveying systems

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

MAKENAS GRAIN MILLING TECHNOLOGY

Turkey

It is used to feed the product regularly into pneumatic conveying pipes at the pneumatic conveying systems

Request for a quote

MAKENAS GRAIN MILLING TECHNOLOGY

Turkey

It is used to separate centrifugally product - air mixture and generally is designed as a product receiver in pneumatic conveying systems

Request for a quote

ALFA BREAD

Turkey

all line is made of food-grade materials - the machines gained ISO and CE certificates - 0ne year warranty- it works by gas or diesel - it is fully automatic. - it works by the pneumatic system - the oven withstands high temperatures. ability to fit big and medium places. our engineers are ready to plan your place.

Request for a quote

ALFA BREAD

Turkey

all line is made of food-grade materials - the machines gained ISO and CE certificates - 0ne year warranty- it works by gas or diesel - it is fully automatic. - it works by the pneumatic system - the oven works by the infrared system and it withstands high temperatures. ability to fit big and medium places. our engineers are ready to plan your place.

Request for a quote

ALFA BREAD

Turkey

all line is made of food-grade materials - the machines gained ISO and CE certificates - 0ne year warranty- it works by gas or diesel - it is fully automatic. - it works by the pneumatic system - the oven withstands high temperatures. ability to fit big and medium places. our engineers are ready to plan your place.

Request for a quote

ALFA BREAD

Turkey

all line is made of food-grade materials - the machines gained ISO and CE certificates - 0ne year warranty- it works by gas or diesel - it is fully automatic. - it works by the pneumatic system - the oven works by the infrared system and it withstands high temperatures. ability to fit big and medium places. our engineers are ready to plan your place.

Request for a quote

ALFA BREAD

Turkey

all line is made of food-grade materials - the machines gained ISO and CE certificates - 0ne year warranty- it works by gas or diesel - it is fully automatic. - it works by the pneumatic system - the oven works by the infrared system and it withstands high temperatures. ability to fit big and medium places. our engineers are ready to plan your place.

Request for a quote

FLEXPLAS

Turkey

FLEXPLAS DRIVEN CONVEYORS are designed to your specifications and adapted to your specific extrusion line and manufacturing requirements for maximum efficiency Flexplas take-away conveyors are designed with tilt/dump tables to be used when cutting flexible hoses and tubing. Typically located directly after cutting devices, Driven Conveyors enhance the cut length tolerance and cut quality by supporting and transporting the hose away from the cutter bushing at adjustable speeds typically more than line speed, eliminating accumulation and sorting confusion. The hose can then be optionally ejected by a pneumatic ejector system into a collection tray for operator removal or for coiling by a winding machine. The driven conveyor automatically discharges parts to a collection tray for this purpose. Our conveyors can be optionally configured for one side or dual side collection which is for double extrusion of the hose on the same extrusion line.

Request for a quote

LESMAK MAKINA SANAYI VE TIC. STI.

Turkey

18-24-32-36 Stations pneumatic and Hydraulic working system, full automatic polyurethane machine for shoes, slippers and shoe soles.

Request for a quote

YILMAZ MACHINE

Turkey

PRODUCT INFORMATION After welding clean up down and corner sides of 90º PVC Profiles after welding. High quality stripping and cleaning operations by means of the hydro-pneumatic system Profile processing capability up to 180 mm of height Practical change of cutter provides ease of operation Fixing the workpiece firmly by means of the vertical and horizontal clamps PLC operation system Centering system to fit the profiles properly on the setsquare Robust machine stand Stripping blade levels are adjustable according to laminated and un laminated profiles Pneumatic tool fixing and releasing system Single or multi cleaning operations can be processed Automatic start up feature when profile placed on the table Stops automatically after stripping and cleaning operation STANDARD ACCESSORIES Air gun OPTIONAL ACCESSORIES Corner cleaning cutters Videolar TECHNICAL SPECIFICATIONS 1200 Wx3 400V AC 50~60 Hz 3000 D/dak RPM D: 215 d: 32 mm. 36 Lt/dak. 6~8 Bar 92x 101x 143 cm 249 kg. 198 kg.

Request for a quote

YILMAZ MACHINE

Turkey

PRODUCT INFORMATION CA 603 Single Corner Cleaning Machines are used for striping of bottom and top surfaces and cleaning outer corners of 90° PVC cleaning profiles. High quality stripping and cleaning operations by means of the hydro-pneumatic system Profile processing capability up to 180 mm of height Practical change of cutter provides ease of operation Fixing the workpiece firmly by means of the vertical and horizontal clamps Stops automatically after stripping and cleaning operation PLC operation system Centering system to fit the profiles properly on the setsquare Robust machine stand Pneumatic tool fixing and releasing system Stripping blade levels are adjustable according to laminated and un laminated profiles Processing capability of 2 different PVC profile 4 different cutter set can be mounted on a modul (CA 603) STANDARD ACCESSORIES Air gun OPTIONAL ACCESSORIES Corner cleaning cutters Videolar TECHNICAL SPECIFICATIONS 1200Wx 2~3 400V AC 50-60 Hz. 3000 D/dak RPM

Request for a quote

YILMAZ MACHINE

Turkey

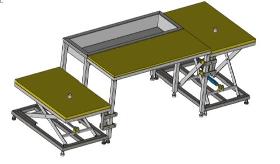

PRODUCT INFORMATION KP 120 machine is designed and constructed for the hydraulically crimping and correct assembly of aluminum profiles. The machine is semiautomatic and the machining cycle of various units are manual controlled by user who always stays outside of the dangerous area. It is designed through the pneumatically crimping system Steel construction of the machine table that is strong and lasting Practically adjustment of the knives according to the shape and height of the profiles Practically adjustment of the cylinder feed and profile stops by means of the millimetric ruler The machine is equipped with the pneumatic (for clamps ) and hydraulic (for crimping ) foot pedals for the operation control during the machining cycle Double-acting centering set-square returns to the home position under the table after crimping Powerful hydraulic pump with 2 x 5 tons capacity Protection plates made of Polyamide material to prevent being scratches on the profile surface

Request for a quoteResults for

Pneumatic system - Import exportNumber of results

53 ProductsCountries

Company type

Category

- Flour milling - machinery and equipment (6)

- Pneumatic conveyor equipment (4)

- Agglomeration and emulsification machines for the food processing industry (4)

- Food Industry - Machines & Equipment (4)

- Machines for the manufacture of PVC and Aluminium Doors and Windows (3)

- Packing and packaging - machinery and equipment (3)

- Bakery - machinery and equipment (3)

- Oils, cooking - machinery and equipment (3)

- Bakery - machinery and equipment (2)

- Concrete preparing - machinery and equipment (2)

- Flour-milling (2)

- Pneumatic system components (1)

- Tools, pneumatic (1)

- Cylinders, pneumatic (1)

- Bottling and filling - machinery and equipment (1)

- Air filtration equipment (1)

- Articulated vehicles and semitrailers (1)

- Bakery ovens (1)

- Cold cuts and prepared meats - machinery and equipment (1)

- Extrusion, plastics - machinery (1)