- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- plc panel

Results for

Plc panel - Import export

PARSMEGA MAKINA

Turkey

It has wide usage opportunities in all areas where engine use is intense, such as production lines, factories, smart buildings, treatment facilities, pump stations. Our panels are designed considering the ease of operation and maintenance of MCC, with standards-compliant solutions for production lines and control that require process control. Our project support, the solutions we produce for control systems with conventional or "process controllers", our knowledge and experience are an important privilege we offer to our customers. Using the right equipment or system in the right place and our complete solutions made with quality equipment are part of our tradition of achieving important criteria such as operational safety and investment efficiency for the benefit of the end user.

Request for a quote

DAMS MACHINE

Turkey

DMOM series are new generation mobile bowl mixers. It has a fast and practical system that allows kneading without losing time thanks to the spare mobile bowl.It has a double-speed motor and belt pulley equipment. The anchor lifting and bowl locking systems are hydraulic. Slow and fast cycle times can be determined by setting the time with the automatic operation mode.It has a faster kneading feature than standard dough kneading machines and the dough kneading process is completed in 15 minutes.It is aimed at meeting fast mass production needs. It can be used in the production of dough, raw meatballs, butter, minced meat, cream, tobacco, snacks and similar products. PRODUCT SPECIFICATIONS Touch Screen PLC Control Panel Hydraulic bowl locking and anchor lifting Differential-free system Water dosing Time setting Double-speed and powerful motor All surfaces in contact with food are made of 304 quality stainless steel

Request for a quote

DAMS MACHINE

Turkey

DIVIDER & ROUNDER Upto 7000 pcs/hour capacity Weight range 40-140 grams (±2 gr) 4 pieces 50mm diameter pistons Changable outer drum for different weights 4 rows outlet belts. Automatic oil lubrication Variable speed controlsfor main drive and rounding unit Flour duster Dough bunker capacity is 140 kg Safety switches on doors Total power 5 kW 7 inc HMI Touch Panel PLC control INTERMEDIATE PROOFER Proofing time 10 minutes (for 4000pcs/hour) 4 pockets stainless steel dough carrier tray 146 pieces active tray 584 active pockets Removable and washable UHMWPE mesh pockets 2″ roller chain for tray transport Main frame is stainless steel tube Total power 1.1 kW Easy Access for maintenance Safety switches on doors

Request for a quote

DAMS MACHINE

Turkey

DIVIDER & ROUNDER Up to 11000 pcs/hour capacity Weight range 40-140 grams (±2 gr) 6 pieces 50mm diameter pistons Changable outer drum for different weights 6 row outlet belts Automatic oil lubrication Variable speed controls for main drive and rounding unit Flour duster Dough bunker capacity is 210 kg Total power 5 kW 7 inc HMI Touch Panel PLC control INTERMEDIATE PROOFER Proofing time 10 minutes (for10.000pcs/hour) 6 pocket stainless steel dough carrier tray 278 pieces active tray 1668 active pockets Removable and washable UHMWPE mesh pockets 2″roller chain for tray transport Main frame is stainless steel tube. Total power 1.5 kW.

Request for a quote

BSM INDUSTRY AND GLOBAL TRADING

Turkey

Electrical panels are vital to ensuring that facilities operate efficiently. We design and manufacture customized electrical panels to meet the specific needs of our customers. We produce ADP, MCC, PLC panels using high quality materials and modern technologies. We offer designs that best meet our customers' needs.

Request for a quote

YMCUP

Turkey

YM/PKT-DK Series machines provide you minimum manpower - minimum labor, provides ease of use with aesthetic desing, clear PLC control panel. You can package all the dimensions in one machine and you can maximize your product quality in the paper cup sector where the product range is very wide. While 1 personnel controls 2 machines in manual paper cup collection, 2 personnel is sufficient for 20 machines in automatic packaging machines.

Request for a quote

YMCUP

Turkey

YM/PKT-DK Series machines provide you minimum manpower - minimum labor, provides ease of use with aesthetic desing, clear PLC control panel. You can package all the dimensions in one machine and you can maximize your product quality in the paper cup sector where the product range is very wide. While 1 personnel controls 2 machines in manual paper cup collection, 2 personnel is sufficient for 20 machines in automatic packaging machines.

Request for a quote

FLEXPLAS

Turkey

Flexplas offers turn-key extrusion lines for Medical Tubing production to the manufacturers in the medical and laboratory equipment sectors. Our customers can produce a broad spectrum of medical hoses out of Flexplas extrusion lines such as flexible PVC medical tubing in O.D. range 2 – 12 mm, PP and PE medical tubing in O.D. range 2 – 4 mm, multi-lumen medical tubing, and more. Flexplas high-speed medical tube extrusion lines are reliable and robust systems to help you serve the medical sector the best quality medical hoses and tubes. Features: *High speed extrusion line for manufacturing of medical tubing *Customized design to meet customer requirements *Master control panel with Smart PLC system with color touch screen. Remote control of the complete line with one master control panel *CE marking certifying full compliance with corresponding EU standards.

Request for a quote

FLEXPLAS

Turkey

Crafted for your profile in a perfect way Flexplas designs and manufactures turn-key extrusion lines for the manufacture of flexible tape and profile. We build all the machines and tooling systems that are necessary for production. Flexplas profile extrusion line boasts the latest technology enabling optimum performance at the highest line speeds. The whole extrusion system is controlled via a single master control panel including a large touchscreen PLC. With our complete equipment you can produce a wide range of hose diameters extending from small to larger, according to your need. Features: *High-speed extrusion line for the best quality profile and tape *Production of sizes as per customer need *Customized design to meet customer requirements *Master control panel with Smart PLC system with color touch screen. *Remote control of the complete line with one master control panel. *Downstream equipment can be separated and installed to another production line when necessary.

Request for a quote

GEO TEKNO LTD. CO.

Turkey

GEO brand drum heating furnaces are specially designed and manufactured based on the requirements of your process. It has a wide barrel capacity from 4 to 32. It offers a wide range of options with its single-chamber or multi-chambered, one- or two-layer production options, and also saves space with its multi-storey production option. Full Automation GEO barrel heating furnaces can be equipped with PLC control panel and HMI display with full automation for process control, reporting, process monitoring and also management of alarm conditions. The heating options of GEO barrel heating furnaces includes systems such as electric heating, open steam heating, and steam coils. Energy Source Open Steam Steam Coils Hot Water Coils Hot Thermal Oil Coils Superheated Water Coils

Request for a quote

LESMAK MAKINA SANAYI VE TIC. STI.

Turkey

A very convenient,practical and functional 2 working stations injection moulding machine for producing compact,extensive,strong,pliable or unpliable,quality shoe soles in 1, 2 or 3 colours from materials such as TR,TPU,TPE and PVC. The main characteristic of the machine is possessing the PLC control.In the machine are used Siemens products.The operator panel of the PLC appliance is touchscreen what makes the usage of the machine quite comfortable.Heating controls are connected to the PLC device.The machine has full automatic,semi-automatic and manual system.In the cooling system which is accordingly designed, in the three parts water circulation channels are installed. The cooling plates are made of pressed aluminium and the cooling is provided as necessary.Due to the technical characteristics the usage of other machines' molds is possible. With this machine at the cost of the ordinary one colour machine widely used you will get 1, 2 and 3 colours Shoe soles injetion moulding machine.

Request for a quote

LESMAK MAKINA SANAYI VE TIC. STI.

Turkey

A very convenient, practical and functional two working stations injection moulding machine for producing compact, extensive, strong, pliable or unpliable, quality shoe soles in single color from materials such as TR, TPU, TPE and Compact/Expand PVC. The main characteristic of the machine is possessing the PLC control. In the machine are used Siemens products. The operator panel of the PLC appliance is touchscreen what makes the usage of the machine quite comfortable. Heating controls are connected to the PLC device. Injection settings are set from the PLC. A pushing system is available in order to take off the soles from the mold. In the mold rotaion system a fully tumble and half tumble system is available. Two Stations Single Color Shoe Soles Injection Machine.

Request for a quote

LESMAK MAKINA SANAYI VE TIC. STI.

Turkey

A very convenient, practical and functional two working stations Shoe Soles Injection Moulding Machine for producing compact, extensive, strong, pliable or unpliable, quality shoe soles in three colours from materials such as TR, TPU, TPE and COMPACT/EXPANSE PVC. The main characteristic of the machine is possessing the PLC control. In the machine are used Siemens products. The operator panel of the PLC appliance is touchscreen what makes the usage of the machine quite comfortable. Heating controls are connected to the PLC device. Injection settings are set from the PLC. A pushing system is available in order to take off the soles from the mold. In the mold rotaion system a fully tumble and half tumble system is available. The machine has full automatic, semi-automatic and manual system. In the cooling system which is accordingly designed, in the three parts water circulation channels are installed.

Request for a quote

LESMAK MAKINA SANAYI VE TIC. STI.

Turkey

A very convenient, practical and functional two working stations injection moulding machine for producing compact, extensive, strong, pliable or unpliable, quality shoe soles in two colours from materials such as TR, TPU, TPE and PVC. The main characteristic of the machine is possessing the PLC control. In the machine are used Siemens products. The operator panel of the PLC appliance is touchscreen what makes the usage of the machine quite comfortable. Heating controls are connected to the PLC device. Injection settings are set from the PLC. A pushing system is available in order to take off the soles from the mold. In the mold rotaion system a fully tumble and half tumble system is available. The machine has full automatic, semi-automatic and manual system. In the cooling system which is accordingly designed, in the three parts water circulation channels are installed. The cooling plates are made of pressed aluminium and the cooling is provided as necessary.

Request for a quote

LESMAK MAKINA SANAYI VE TIC. STI.

Turkey

A very convenient, practical and functional two working stations injection moulding machine for producing compact, extensive, strong, pliable or unpliable, quality shoe soles in two colours from materials such as TR, TPU, TPE and PVC. The main characteristic of the machine is possessing the PLC control. In the machine are used Siemens products. The operator panel of the PLC appliance is touchscreen what makes the usage of the machine quite comfortable. Heating controls are connected to the PLC device. Injection settings are set from the PLC. A pushing system is available in order to take off the soles from the mold. In the mold rotaion system a fully tumble and half tumble system is available. For each machine's administration, has been placed either hydraulic central or electrical central and the maintenance is done by the easily accessible centrals. Due to the technical characteristics the usage of other machines' molds is possible.

Request for a quote

ROTAKEM

Turkey

Technicial Specifications 1. Origin: Italy 2. Year of production: 1996 3.Refurbishment year: 2020 4. Motor power: 220 kW 5.Rotor structure: tangensial with 4 blades 6.Rotor speed: 44/36 rev / min 7.Dump system: sliding cover 8.Heat exchanger gearbox 9.Ram - pneumatic 10. Temperature control 11. Drinking cooling system 12. Original chassis 13. New electrical panel (PLC Control) 14. PLC control

Request for a quote

EFARGE MAKINA IMALAT SAN. VE TIC. A.S.

Turkey

Disc Diameter : Ø 300 - 400 Size Calibration System : Servo (Ball Screw + Linear Guides) Max. Cutting Thickness : 50 mm Min. Cutting Width : 200 mm Max. Belt Width : 1200 mm Control Panel : PLC + SCREEN Automatic Water Valves : Available Conveyor Belt Speed : 0-8 mt/dk Line Length ≌ 10000 mm

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

GRIFT MAKINA

Turkey

Powder products packaging machine. The price changes according to the desired sensitivity and weight. Flour,powder coating,,salep,coffee v.b filling machine for powder groups Easy and clear control panel with touch plc screen Automation and mechanical systems are completely manufactured in our structure. It is designed for companies that are just starting out and have low production capacity. It is quite simple and precise to use. As a type of bag, it is suitable for use for ready-made bags. It has automatic feeding and can do fast and precise weighing on ready-made bags. Pieces may vary by minutes upon request and request. A controllable servo motor is available for a fast and precise filling. The desired product weight is obtained by the number of turns of the filling screw. The size and dimensions of the screw may vary depending on the type of product and the desired filling amount. The mixer system located inside the chamber prevents the product from jamming.

Request for a quote

GRIFT MAKINA

Turkey

It works with the pneumatic system. Ability to make precise filling with manual 1% accuracy of weight adjustment We are able to manufacture STANDARD production machines between 0-5000 KG. Dec. We are able to manufacture special production machines between 5000-25000 Dec. We have the possibility of customer-specific design. Easy and clear control panel with touch plc screen Automation and mechanical systems are completely manufactured in our structure. It is suitable for precise and fast packaging of granular products. Control is provided by a separate processor independent of the machine. Control is provided by a separate touch screen independent of the machine. It provides possibilities such as automatic cleaning, automatic product feeding and different language options. It is manufactured with different sizes, types, speeds and different number of pads. Compared to these, the shrouds are easy to disassemble and easy to clean.

Request for a quote

GRIFT MAKINA

Turkey

It works with the pneumatic system. Ability to make precise filling with manual 1% accuracy of weight adjustment We are able to manufacture STANDARD production machines between 0-5000 KG. Dec. We are able to manufacture special production machines between 5000-25000 Dec. We have the possibility of customer-specific design. Easy and clear control panel with touch plc screen Automation and mechanical systems are completely manufactured in our structure. It is suitable for precise and fast packaging of granular products. Control is provided by a separate processor independent of the machine. Control is provided by a separate touch screen independent of the machine. It provides possibilities such as automatic cleaning, automatic product feeding and different language options. It is manufactured with different sizes, types, speeds and different number of pads. Compared to these, the shrouds are easy to disassemble and easy to clean.

Request for a quote

GLOBMAC GLOBAL BLOCK MACHINES

Turkey

This machine is designed to produce inter locks , blocks. insulated blocks, curbstone it can produce 140-150 pallet per hour 25 interlocks pcs/1 press 10 blocks pcs / 1 press press time is 25-30 seconed it has two system: full automatic and semi automatic it can be use with stacking system or with out stacked pallet must be transport with forklift for machine with stacking system. machine works on the wooden pallet there are two types of mortar reading system. It is manual and automatic weighing system cement water and sand weighn and mortar are mixed all motions on the machine provided by hydraulic system movements on the system will be controlled by PLC automation system via sensors in automaticmachine, machine press number unit of productions , problems on the machine can be seen on the PLC touchscreen panel.

Request for a quote

GLOBMAC GLOBAL BLOCK MACHINES

Turkey

This machine has been designed in order to produce high quality of interlocks, blocks,curbstones and other concrete products as requested by the customer. One press can produce 42pcs of interlocks or 18 pcs from blocks 20x40x20cm block and curbstones. The machine can be used with a stacking system or without stacking system. The press time is 20-24 seconds. It has two working system, it can work either full automatic or semi automatic depending on user preference. Movements on the system will be controlled by a PLC. Auto motion system via sensors in automatic machine. Machine press number, unit of productions, problems on the machine can be seen on the PLC touch screen panel. The stacked Pallet must be transported using a forklift for machines with a stacking system. The machine works on wooden pallets which are made of pine wood. There are two types of mortar preparation system it can be either manual or with automatic weighing system after the cement is dosed sand is been weighed.

Request for a quote

GLOBMAC GLOBAL BLOCK MACHINES

Turkey

This machine has been designed in order to produce interlocks,blocks,curbstones and other concrete products as requested by the customer. In one press it can produce 36 pcs of interlocks, or 12 pcs of 20x40x20cm block The press time is 18-22 seconds. It has two working system, it can work either on full automatic or semi automatic depending on user preference. The machine can be used with a stacking system or without a stacking system. Movements on the system will be controlled by plc. Auto motion system via sensors in automatic machine. Machine press number, unit of productions, problems on the machine can be seen on the PLC touch screen panel. The stacked Pallet must be transported using a forklift for machines with a stacking system. The machine works on wooden pallets which are made of pine wood there are two types of mortar preparation system it can be either manual or with automatic weighing system after the cement is dosed sand is been weighed then transported up to the mixer.

Request for a quote

GRIFT MAKINA

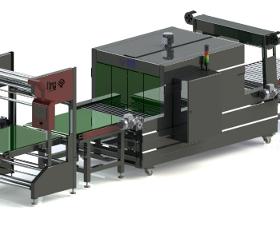

Turkey

We have the production of machines in the desired sizes and dimensions. Easy and clear control panel with touch plc screen Automation and mechanical systems are completely manufactured in our structure. There are special production machines in our production. It is designed to pack your desired size products in a precise and fast way. Design and production are carried out according to the desired product type and specifications. It is suitable for products that do not melt with an instant temperature of 200 degrees in the tunnel. It has a sensitive and fast retention feature with SSR switching system. The supply voltage is 380 V/ 50 Hz.

Request for a quoteResults for

Plc panel - Import exportNumber of results

25 ProductsCountries

Company type

Category

- Agglomeration and emulsification machines for the food processing industry (4)

- Shoes - industrial machinery (4)

- Brick-making - machinery and equipment (3)

- Bakery and confectionery industry - machinery and equipment (2)

- Paper and cardboard manufacturing - machinery and equipment (2)

- Bakery - machinery and equipment (1)

- Bakery - machinery and equipment (1)

- Cocoa and chocolate - machines and equipment (1)

- Extrusion, plastics - machinery (1)

- Forming, rubber - machinery (1)

- Furnaces, ovens and kilns, electric (1)

- Injection moulding of rubber and plastic (1)

- Marble cutting machines (1)

- Oils, cooking - machinery and equipment (1)

- Plastic products for the medical industry (1)

- Trade organisations (1)