- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- plastic injection products

Results for

Plastic injection products - Import export

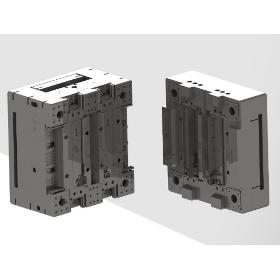

GRI MOLD AND PLASTIC CO.

Turkey

With more than 20 years of experience, Gri Kalıp manufactures molds in world standards. Our company aims to achieve optimal price-quality balance in all projects by adopting the experience and quality standards that it has gained abroad especially in plastic injection molds. Increasing the production capacity of our company, reducing the costs of mold production, is also of great importance for the development of our industry at the same time. Because the greatest cost in mold production is the time of labor and engineering, we aim to shorten the time by producing practical solutions in mold systems with more efficient working principle and not compromising our quality standards or mold materials. For you, Gri Kalıp can be included in the mold making process and you can take advantage of these experiences.

Request for a quote

GRI MOLD AND PLASTIC CO.

Turkey

With more than 20 years of experience, Gri Kalıp manufactures molds in world standards. Our company aims to achieve optimal price-quality balance in all projects by adopting the experience and quality standards that it has gained abroad especially in plastic injection molds. Increasing the production capacity of our company, reducing the costs of mold production, is also of great importance for the development of our industry at the same time. Because the greatest cost in mold production is the time of labor and engineering, we aim to shorten the time by producing practical solutions in mold systems with more efficient working principle and not compromising our quality standards or mold materials. For you, Gri Kalıp can be included in the mold making process and you can take advantage of these experiences.

Request for a quote

GRI MOLD AND PLASTIC CO.

Turkey

With more than 20 years of experience, Gri Kalıp manufactures molds in world standards. Our company aims to achieve optimal price-quality balance in all projects by adopting the experience and quality standards that it has gained abroad especially in plastic injection molds. Increasing the production capacity of our company, reducing the costs of mold production, is also of great importance for the development of our industry at the same time. Because the greatest cost in mold production is the time of labor and engineering, we aim to shorten the time by producing practical solutions in mold systems with more efficient working principle and not compromising our quality standards or mold materials. For you, Gri Kalıp can be included in the mold making process and you can take advantage of these experiences.

Request for a quote

GRI MOLD AND PLASTIC CO.

Turkey

With more than 20 years of experience, Gri Kalıp manufactures molds in world standards. Our company aims to achieve optimal price-quality balance in all projects by adopting the experience and quality standards that it has gained abroad especially in plastic injection molds. Increasing the production capacity of our company, reducing the costs of mold production, is also of great importance for the development of our industry at the same time. Because the greatest cost in mold production is the time of labor and engineering, we aim to shorten the time by producing practical solutions in mold systems with more efficient working principle and not compromising our quality standards or mold materials. For you, Gri Kalıp can be included in the mold making process and you can take advantage of these experiences.

Request for a quote

GRI MOLD AND PLASTIC CO.

Turkey

With more than 20 years of experience, Gri Kalıp manufactures molds in world standards. Our company aims to achieve optimal price-quality balance in all projects by adopting the experience and quality standards that it has gained abroad especially in plastic injection molds. Increasing the production capacity of our company, reducing the costs of mold production, is also of great importance for the development of our industry at the same time. Because the greatest cost in mold production is the time of labor and engineering, we aim to shorten the time by producing practical solutions in mold systems with more efficient working principle and not compromising our quality standards or mold materials. For you, Gri Kalıp can be included in the mold making process and you can take advantage of these experiences.

Request for a quote

AYBERKSAN PLASTIK KALIP SANAYI

Turkey

One of the most popular sectors in the field of Injection Molding and Plastic Injection is the Automotive Sector. In general, the majority of automotive accessories consist of plastic and rubber. This is the most important indicator that injection molds and plastic injection products maintain their value. The markets formed in the global world have almost taken on the nature of domestic markets, and competition between countries has gained momentum. AYBERKSAN Plastic Mold Industry takes the necessary steps one by one, with quality and corporate awareness, for its goals to become a brand in both local and world markets.

Request for a quote

AYBERKSAN PLASTIK KALIP SANAYI

Turkey

Drilling works in our country started with the establishment of MTA in 1935. With the 1950s, drilling applications started not only in the field of oil extraction, but also in the field of mining and natural resources. After the 1970s, the number of private drilling companies has increased and today it is over 1000. With the development of the drilling industry, the use of plastic injection products has increased. The parts, which are mostly called plastic gaskets and felts, are produced and used as plastic injection. Molds of gaskets made of rubber are also produced within our company and product prints are taken. Rubber and plastic seals etc. belonging to the equipment used in this sector. As AYBERKSAN Kalıp Sanayi, we bring the products together with the end user.

Request for a quote

GRI MOLD AND PLASTIC CO.

Turkey

With more than 20 years of experience, Gri Kalıp manufactures molds in world standards. Our company aims to achieve optimal price-quality balance in all projects by adopting the experience and quality standards that it has gained abroad especially in plastic injection molds. Increasing the production capacity of our company, reducing the costs of mold production, is also of great importance for the development of our industry at the same time. Because the greatest cost in mold production is the time of labor and engineering, we aim to shorten the time by producing practical solutions in mold systems with more efficient working principle and not compromising our quality standards or mold materials. For you, Gri Kalıp can be included in the mold making process and you can take advantage of these experiences.

Request for a quote

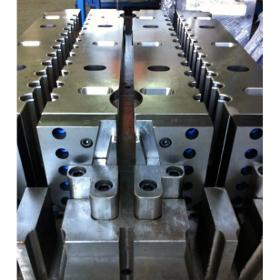

KARADUMAN KALIP

Turkey

Taking care to prioritize high precision and low tolerance in plastic injection mold production, Karaduman Kalıp maintains its quality standards by using CAD-CAM technology in its computer-controlled benches. Being aware of the fact that today's technologies are progressing rapidly by competing with time and that the plastic injection mold industry is one of the important elements of this race, Karaduman Kalıp aims to be a pioneer in the sector and to provide quality service, to make the production process short and scalable, to ensure the consistency of our deadlines, to provide quality in details that require high precision. and constantly invests in the CNC track in order to be perfect. With its experienced team in mold production, Karaduman Kalıp increases its production day by day with its infrastructure and machine park suitable for today's technologies.

Request for a quote

KARADUMAN KALIP

Turkey

Taking care to prioritize high precision and low tolerance in plastic injection mold production, Karaduman Kalıp maintains its quality standards by using CAD-CAM technology in its computer-controlled benches. Being aware of the fact that today's technologies are progressing rapidly by competing with time and that the plastic injection mold industry is one of the important elements of this race, Karaduman Kalıp aims to be a pioneer in the sector and to provide quality service, to make the production process short and scalable, to ensure the consistency of our deadlines, to provide quality in details that require high precision. and constantly invests in the CNC track in order to be perfect. With its experienced team in mold production, Karaduman Kalıp increases its production day by day with its infrastructure and machine park suitable for today's technologies.

Request for a quote

3D ENDÜSTRI

Turkey

Far-San Automotive have been manufacturing with headlights, tail lamp, signal lamp and fog lamp to cars and commercial vehicles since 1991. Our production in a closed area of 5000m2; 40% of exports and 60% continues to be our domestic market sales. We import to a lot of country quality assurance by Far-San Automotive. We have got ISO 9001 quality certificate and we have applied E mark type approval to service. You can check our website www.far-san.com.tr and you can be reached our products. If you would need our products catalogue so i can send to as pdf file including all products. At the same time, we provide services in plastic injection, aluminum injection mold and product production.

Request for a quote

3D ENDÜSTRI

Turkey

Far-San Automotive have been manufacturing with headlights, tail lamp, signal lamp and fog lamp to cars and commercial vehicles since 1991. Our production in a closed area of 5000m2; 40% of exports and 60% continues to be our domestic market sales. We import to a lot of country quality assurance by Far-San Automotive. We have got ISO 9001 quality certificate and we have applied E mark type approval to service. You can check our website www.far-san.com.tr and you can be reached our products. If you would need our products catalogue so i can send to as pdf file including all products. At the same time, we provide services in plastic injection, aluminum injection mold and product production.

Request for a quote

ATABEY PLASTIC RECYCLING COMPANY LTD

Turkey

we are looking forward to establishing business relationship with many companies over the world our products pp granules Injection -polypropylene its brief description of the chemicals we are interested to sell Pp Recycled granules polypropylene pp recycled granules Injection (PP) is used in the manufacture of plastic components for the automotive industry and Many important industries. The PP granules produced in our factory meet all the requirements of plastic Injection manufacturers We can supply products to all over the world with high quality and reasonable prices We provide supply solutions for a variety of plastice granules recycled products with Our distribution strengths include Forging relationships with suppliers and manufacturer and producers of plastic granules recycled across the globe to reliably source high-quality Purity 95%pp, competitively-priced raw materials Our mission is to fulfill customers' needs for high quality products with an efficient, reliable

Request for a quote

ATABEY PLASTIC RECYCLING COMPANY LTD

Turkey

we are looking forward to establishing business relationship with many companies over the world our products pp granules Injection -polypropylene its brief description of the chemicals we are interested to sell Pp Recycled granules polypropylene pp recycled granules Injection (PP) is used in the manufacture of plastic components for the automotive industry and Many important industries. The PP granules produced in our factory meet all the requirements of plastic Injection manufacturers We can supply products to all over the world with high quality and reasonable prices We provide supply solutions for a variety of plastice granules recycled products with Our distribution strengths include Forging relationships with suppliers and manufacturer and producers of plastic granules recycled across the globe to reliably source high-quality Purity 95%pp, competitively-priced raw materials Our mission is to fulfill customers' needs for high quality products with an efficient, reliable

Request for a quote

ATABEY PLASTIC RECYCLING COMPANY LTD

Turkey

we are looking forward to establishing business relationship with many companies over the world our products pp granules Injection -polypropylene its brief description of the chemicals we are interested to sell Pp Recycled granules polypropylene pp recycled granules Injection (PP) is used in the manufacture of plastic components for the automotive industry and Many important industries. The PP granules produced in our factory meet all the requirements of plastic Injection manufacturers We can supply products to all over the world with high quality and reasonable prices We provide supply solutions for a variety of plastice granules recycled products with Our distribution strengths include Forging relationships with suppliers and manufacturer and producers of plastic granules recycled across the globe to reliably source high-quality Purity 95%pp, competitively-priced raw materials Our mission is to fulfill customers' needs for high quality products with an efficient, reliable

Request for a quote

AYBERKSAN PLASTIK KALIP SANAYI

Turkey

Most of the plastic products are produced by injection method. Injection in summary; It is the process of injecting the melted raw material into the mold at a certain temperature and proportion and obtaining the plastic product after it cools. It is a method widely used in Turkey and in the world. As AYBERSAN Plastik Kalıp Sanayi, we also house the plastic injection process, which is an indispensable part of our injection mold production, within our company. Plastic injection; raw material amount, machine temperature, runner temperature, cooling time etc. It is a process that includes many factors at the same time. If it is not done by experts, there may be burrs, depressions, bursts, etc. in the product. undesirable consequences are inevitable. Our company, which sees quality and satisfaction as equivalent, has made and continues to make all necessary investments in this regard.

Request for a quote

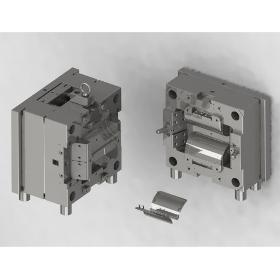

NOVELTY STEEL

Turkey

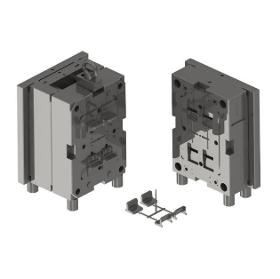

The mold comprises two main parts: the injection mold (A plate) and the ejector mold (B plate), which are also known as moulder and mouldmaker. Plastic resin is introduced into the mold via a sprue or gate in the injection mold. The sprue bushing seals tightly against the nozzle of the injection barrel of the molding machine, allowing molten plastic to flow from the barrel into the mold, known as the cavity. The sprue bushing guides the molten plastic into the cavity impressions through channels on the A and B plates. These channels, called runners, enable the plastic to flow along them. The molten plastic moves through the runner and enters specialized gates, ultimately filling the cavity geometry to create the desired part.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

CENAR MOLD AND PLASTIC INJECTION PARTS

Turkey

Plastic caps for parfume/cologne bottles

Request for a quote

CENAR MOLD AND PLASTIC INJECTION PARTS

Turkey

Plastic injected parts for different markets

Request for a quote

CENAR MOLD AND PLASTIC INJECTION PARTS

Turkey

Plastic injected hookah parts

Request for a quote

CENAR MOLD AND PLASTIC INJECTION PARTS

Turkey

Plastic injection parts for different markets

Request for a quote

CENAR MOLD AND PLASTIC INJECTION PARTS

Turkey

Injected Plastic Caps for cosmetic industry

Request for a quote

CENAR MOLD AND PLASTIC INJECTION PARTS

Turkey

Plastic Injected Automotive Parts

Request for a quote

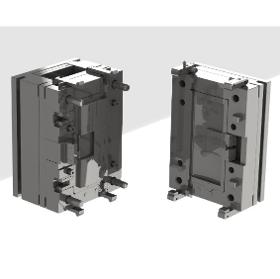

GRUP HS MAKINE KALIP SAN. VE TIC. LTD. STI.

Turkey

The knowledge of design plastic injection mould is not enought, it is also important that the knowledge of operating plastic injection machine and polymer characteristics. Parameters used in injection machine are material injection temperature, injection pressure, speed, press time and push up feature. Designing injection mould with the knowledge of these characteristic provide both clients and us optimized mould manufacturing. Thanks to the plastic injection machine, founded in company structure, we are aware of following parameters. Our 30 years experienced staff can predict potential mistakes and we warrant trouble free and long duration mould manufacturing. We are assertive on low-cost and high piece injection capacity because of studying in design of modular calculation and flow diagram. Shrinkage of different materials are calculated with the 3D drawing programs by mechanical engineers of our company.

Request for a quote

CENAR MOLD AND PLASTIC INJECTION PARTS

Turkey

Plastic caps for different markets

Request for a quoteResults for

Plastic injection products - Import exportNumber of results

26 ProductsCountries

Company type

Category

- Injection, plastics - machinery (12)

- Plastics moulding (8)

- Injection moulding of rubber and plastic (5)

- Drilling services (2)

- Reinforced plastics - moulding (2)

- Spare parts for cars (2)

- Damaged goods - recovery and recycling (1)

- Films, plastic (1)

- Import-export - coal (1)

- Plastic products for the electrical industry (1)