- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- paper processing

Results for

Paper processing - Import export

BESER KIMYA SAN. VE TIC. LTD.STI.

Turkey

Silicon oil, silicon free ester and mineral oil based different sort of defoamers and antifoam used for wastewater treatment, automotive, textile, paint&coating, biogas production, paper and corrugated board, sugar processing, fermantation, oilfield

Request for a quote

ADVANCED ENGINEERING WEDGE WIRE

Turkey

The bicylinder screen also called drilled press screen is used for special filtering applications with highefficiency filtration. The drilled screen consists of a counterbore hole and looks perforated. Counterbore holes can be manufactured in different diameter and depths.Moreover, screens can also be manufactured in different thicknesses depending on your request and application. Advantages The bicylindrical perforated screen provides different advantages for filtration as a type of special filter screen in different industries. The main advantages of the bicylindrical drilled screen are listed below as Special filtration Counterbore and customized filtration holes Corrosion resistance High durability – long service life Precisely drilled holes Special surface treatment Applications Typical industries and applications of bicylindrical screens are Sugar Pulp Pressing Water Filtration Paper Mills Pressing Processing of Chemicals Seperation Process

Request for a quote

ADVANCED ENGINEERING WEDGE WIRE

Turkey

The bicylinder screen also called drilled press screen is used for special filtering applications with high efficiency filtration. The drilled screen consists of a counterbore hole and looks perforated. Counterbore holes can be manufactured in different diameter and depths. Moreover, screens can also be manufactured in different thicknesses depending on your request and application. Advantages 1-Special filtration 2-Counterbore and customized filtration holes 3-Corrosion resistance 4-High durability – long service life 5-Precisely drilled holes 6-Special surface treatment Applications 1-Sugar Pulp Pressing 2-Water Filtration 3-Paper Mills 4-Pressing 5-Processing of Chemicals 6-Seperation Process

Request for a quote

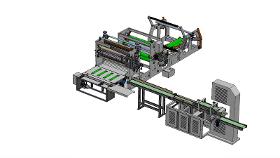

DDC TEKNOLOJI VE MAKINA SAN. A.S.

Turkey

Napkin Production Machine is an industrial level machine designed for mass production of napkins. Modern napkin manufacturing machines meet high standards in terms of both quality and efficiency and have a wide range of uses. Napkin Production Machine is an industrial machine used to produce napkins from raw paper material. This machine automatically performs the processes of cutting, folding and sometimes printing the paper. The main purpose of the machine is to meet the demand by producing napkins at high speed and continuously. Fast Production Capacity: Continuous and fast napkin production. Multifunctional Operations: Ability to perform operations such as cutting, folding and printing together. Flexible Production Options: Ability to produce napkins in different sizes and patterns. User Friendly Interface: Easy operation and adjustable functions. Napkin Production Machine is used in places such as napkin producing factories and paper processing plants.

Request for a quote

DDC TEKNOLOJI VE MAKINA SAN. A.S.

Turkey

Accumulator, the transfer machine is a device that plays an important role in the production processes of toilet paper and kitchen towel rolls, increasing the efficiency of production lines. This equipment automates the storage, sorting and dispatching of rolls, ensuring that the production process is uninterrupted and orderly. This device which is widely used in modern toilet paper production facilities, significantly increases the efficiency of the production line and product quality. The Roll/Log Accumulator is a device that transfers the produced rolls of toilet paper or kitchen towels to the next unit and regulates the flow in the production process. This accumulator is designed to prevent possible disruptions in the production line and to ensure a continuous production flow. It facilitates the organised processing and packaging of the rolls in the production process and allows the glue to dry before the rolls are cut to the desired size.

Request for a quote

DDC TEKNOLOJI VE MAKINA SAN. A.S.

Turkey

Automatic Dual Toilet Paper and Kitchen Towel Winding Machine has an important place in the processes of winding the main bobbins into rolls by passing through the embossing and lamination unit. This machine, with its double embossing and lamination system feature, winds with two different embossing techniques at high speed. Offering a continuous and effective solution in paper production, this machine plays an indispensable role in modern production facilities. Automatic Dual Toilet Paper and Kitchen Towel Wrapping Machine is an industrial machine that can wrap products with two different embossing techniques in a single machine and thus meet the demands of different customer groups. Double Embossing Technique: Ability to wrap products with two different embossing patterns. High Efficiency: Fast and uninterrupted production capacity. Flexible Production Options: Ability to process paper of different sizes and thicknesses. User Friendly Design: Easy operation and adjustable features.

Request for a quote

DDC TEKNOLOJI VE MAKINA SAN. A.S.

Turkey

Automatic Mono Toilet Paper and Kitchen Towel Production Line is an efficiency and quality-oriented technology that realises toilet paper and kitchen towel production on a single line. This production line stands out with its high speed and continuous production capability in modern paper production processes. The ability to produce both toilet paper and kitchen towels on a single line simplifies production processes and increases productivity.Automatic Mono Toilet Paper and Kitchen Towel Production Line is a system that can produce both toilet paper and kitchen towels in a single production line. The main feature of this line is that it can produce both products at high quality standards and continuously. In this way, more production can be done in less space. Double Product Production on a Single Line: Both toilet paper and kitchen towel production. High Productivity: Continuous and fast production processes.

Request for a quote

DDC TEKNOLOJI VE MAKINA SAN. A.S.

Turkey

Combining aesthetics and functionality in toilet paper and kitchen roll production, the 5 Embossed Toilet Paper and Kitchen Roll Machine has a technology that gives extra softness and absorbency to paper products. The embossing process increases both, the visual and tactile quality of the product by adding embossed patterns to the paper surface. If high quality and standard are needed for toilet paper and kitchen rolls, this machine is ideal. The Toilet Paper and Kitchen Roll Machine with 5 Embossings is a production machine that adds special embossed patterns to paper products. This machine adds aesthetic and functional reliefs to the surface of toilet paper and kitchen rolls by using special embossing rollers. These embossings increase the paper’s softness and absorbency, thus improving the product quality. High Quality Embossing Process: it gives an aesthetic and tactile superiority to paper products.

Request for a quote

DDC TEKNOLOJI VE MAKINA SAN. A.S.

Turkey

Industrial Log Saw Cutting Machine plays an important role in the jumbo product production process in the paper converting industry. This machine is designed to cut large diameter toilet paper and kitchen towel rolls (logs) in specified dimensions and with high cutting precision. Jumbo products are toilet paper and kitchen towels used in the industry, which are generally large in diameter and tightly wound in the winding unit. This machine which is suitable for cutting jumbo rolls is equipped with advanced technologies to increase the speed and efficiency of the production process. Industrial Log Saw Cutting Machine is a high capacity machine used to cut jumbo rolls in specified sizes. With the eccentric cutting feature of the log saw blade and motor power, it cuts even very tightly wrapped rolls smoothly. High Cutting Speed and Precision: Capacity to make fast and precise cuts. Large Capacity: Ability to cut jumbo rolls smoothly and with little waste.

Request for a quote

DDC TEKNOLOJI VE MAKINA SAN. A.S.

Turkey

Toilet paper production requires effective and efficient machines, especially in cases requiring high volume production. The 4 Channels Log Saw Toilet Paper Cutting Machine is an advanced and high capacity cutting machine that plays an important role in toilet paper production processes. Due to its four separate channels, this machine cuts four different toilet paper rolls at the same time which significantly increases the production capacity and efficiency. With its advanced technology and high-speed processing ability, it has become an indispensable part of large-scale toilet paper production facilities. The 4 Channels Log Saw Toilet Paper Cutting Machine is a highly efficient industrial machine designed to cut long and continuous toilet paper rolls (logs) to specified dimensions. This machine, which has four separate cutting channels, cuts four different rolls at the same time, significantly increasing the speed and capacity of the production process.

Request for a quote

DDC TEKNOLOJI VE MAKINA SAN. A.S.

Turkey

At the present, toilet paper production has become an industry that requires high speed and efficiency. The 2 Channels Log Saw (Toilet Paper Cutting Machine) is a critical part of this process and is an industrial machine with advanced Technology that allows toilet paper rolls (logs) to be cut in standart sizes and with high precision. By making sharp cuts at high speed, this machine significantly increases both the efficiency of the toilet paper production process and product quality. Moreover, its rapid adaptation to ever-changing market demands makes this machine indispensable for toilet paper production facilities. The 2 Channels Log Saw Toilet Paper Cutting Machine is a high capacity industrial machine designed to cut long and continuous toilet paper rolls (logs) according to specified dimensions. The most important feature of this machine is its two-channel structure.

Request for a quote

DDC TEKNOLOJI VE MAKINA SAN. A.S.

Turkey

Z Fold Dispenser Napkin Machine is a machine that packs paper napkins by folding them in ‘Z’ shape and makes them suitable for use in dispensers. This folding method allows the napkins to be removed individually and easily, which provides fast and practical use, especially in busy environments. Z-folded napkins are a preferred option in modern service areas and homes by providing ease of use. Highlights of this machine include the following: Z Folding Technique: Folds napkins in a special 'Z' shape. High Production Capacity: Suitable for the production of large quantities of napkins. Flexible Production Options: Ability to process paper of different sizes and thicknesses. Z Fold Dispenser Napkin Machine is frequently used for the production of napkins suitable for quick service restaurants, cafes, hotels and other service sectors Maintenance of the Z Fold Dispenser Napkin Machine is important to keep the machine running efficiently and smoothly.

Request for a quote

PEAK UNIVERSAL BUSINESS, PETROCHEMICALS, MINING, MANUFACTURING, TRADING LTD.

Turkey

Oxidised Asphalt 85/25 uses in the chemical, fuel, paints, lacquers, varnishes, paper-pulp-board, textile processing. Also it`s using in road construction, pavement ,crack seal and repairmen, civil works, roofing, construction industries; sealing and insulating buildings, adhesive, construction materials additive, dust-binding, coating, insulating and impregnating agent, make rubber and plastic products. commercial@pub-ltd.com WhatsApp: 00905354837392

Request for a quote

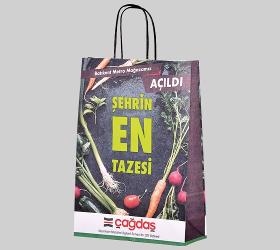

KRAFTTURK PACKAGING

Turkey

Paper bag with twisted handle. Bag made of natural(brown) kraft paper with full process printing and twisted handle. Disclaimer: All trademarks and pictures shown here are as example of our production capability.

Request for a quote

KRAFTTURK PACKAGING

Turkey

Paper bag with twisted handle. Bag made of white kraft paper with full process printing and twisted handle. Disclaimer: All trademarks and pictures shown here are as example of our production capability.

Request for a quote

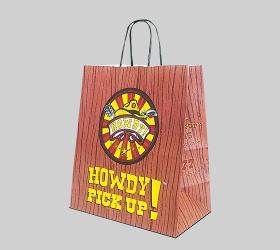

KRAFTTURK PACKAGING

Turkey

Paper bag with twisted handle. Bag made of white kraft paper with full process printing and twisted handle. Disclaimer: All trademarks and pictures shown here are as example of our production capability.

Request for a quote

KRAFTTURK PACKAGING

Turkey

Paper bag with twisted handle. Bag made of white kraft paper with full process printing and twisted handle. Disclaimer: All trademarks and pictures shown here are as example of our production capability.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

KRAFTTURK PACKAGING

Turkey

Paper bag with twisted handle. Bag made of white kraft paper with full process printing and twisted handle. Disclaimer: All trademarks and pictures shown here are as example of our production capability.

Request for a quote

KRAFTTURK PACKAGING

Turkey

Paper bag with twisted handle. Bag made of white kraft paper with full process printing and twisted handle. Disclaimer: All trademarks and pictures shown here are as example of our production capability.

Request for a quote

KRAFTTURK PACKAGING

Turkey

Paper bag with twisted handle. Bag made of white kraft paper with full process printing and twisted handle. Disclaimer: All trademarks and pictures shown here are as example of our production capability.

Request for a quote

KRAFTTURK PACKAGING

Turkey

Paper bag with twisted handle. Bag made of white kraft paper with full process printing and twisted handle. Disclaimer: All trademarks and pictures shown here are as example of our production capability.

Request for a quote

KRAFTTURK PACKAGING

Turkey

Paper bag with twisted handle. Bag made of natural(brown) kraft paper with full process printing and twisted handle. Disclaimer: All trademarks and pictures shown here are as example of our production capability.

Request for a quote

YENIADA FLEXO PRINTING MACHINERY

Turkey

Yeniada 4 Colors Flexo printing machine. 7 inches touch control panel , autamic tension control , 4 kW motor with belt drive , manuel printing arrangemenet. Pneumatic printing roller up and down system. Rubber Roller ink transfer system. Compatible with PP , OPP , CPP nylon materials. Compatible with paper printing , paper cup printing process. Durable design , well known brands used as electrical or mechanical components long lasting maintenance . 4+0, 3+1 , 2+2 printing options. 4+4 is avaible with special material turning frame. Dr. Blade Chamber System , All servo drive , edge control system, camera control system and crane or hydraulic lifting system for heavy rollers are options.

Request for a quote

NEWVIZYON MAKINE

Turkey

Napkin sizes, emboss unit style & number (single or double embossing unit) are optional, depends on customer choices.) Adjustable electronic photocell counter. Electronic Loop and Side Control improve the final product quality. All cylinders contain lubrication system. Double bobbing hangers minimize the downtime through a non-stop paper feeding.

Request for a quoteResults for

Paper processing - Import exportNumber of results

25 ProductsCompany type

Category

- Paper bags (10)

- Napkins, paper (4)

- Toilet paper (3)

- Paper - processing machinery (1)

- Packing and packaging - machinery and equipment (1)

- Flexography - machines (1)

- Accumulators and batteries (1)

- Bitumens (1)

- Blades for saws and cutting machines (1)

- Film printing equipment (1)

- Filtering equipment and supplies (1)

- Water treatment, industrial - systems and equipment (1)