- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- or press

Results for

Or press - Import export

PERGEL METAL

Turkey

CNC Press Brake puts the raw material that is in the form of metal or press into a new form by twisting it. It is a hair styling loom. In the old days, it was called caka, which was used more primitively in accordance with the possibilities. CNC Press decoiler bending machines are pressed between a mold to give a new shape. Hair is a metal loom. The lower and upper moldings are called male and female. In our company, cnc press brake is made of twist. A hydraulic pressure is applied. In press brake bending, the operation is performed by applying force. There are control panels that provide the principle of operation. Such characteristics of materials as their quality, type, thickness and pressure are also important.

Request for a quote

ADVANCED ENGINEERING WEDGE WIRE

Turkey

The bicylinder screen also called drilled press screen is used for special filtering applications with highefficiency filtration. The drilled screen consists of a counterbore hole and looks perforated. Counterbore holes can be manufactured in different diameter and depths.Moreover, screens can also be manufactured in different thicknesses depending on your request and application. Advantages The bicylindrical perforated screen provides different advantages for filtration as a type of special filter screen in different industries. The main advantages of the bicylindrical drilled screen are listed below as Special filtration Counterbore and customized filtration holes Corrosion resistance High durability – long service life Precisely drilled holes Special surface treatment Applications Typical industries and applications of bicylindrical screens are Sugar Pulp Pressing Water Filtration Paper Mills Pressing Processing of Chemicals Seperation Process

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

Wet processing-washing is, in most cases, cleaning and separation of materials by use of water and mechanical forces. It is often followed by the removal of such impurities from raw materials as ores, minerals, sand, and gravels. The process commences by the introduction of the said raw materials in a wash plant and thorough soak with plenty of water. This initial saturation softens and loosens the unwanted materials, making them easier to separate from the valuable base material. Inside the wash plant, zones of high pressure and the whirling impact of paddles and jets alternately whip and beat the mixture, scouring away dirt, clays, silt, and all other contaminants. The continuous movement of water helps to further dislodge these impurities, allowing for a more thorough cleaning.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

Filter press systems are equipment used in separating solids from liquids in various industrial processes. The system includes a series of filter plates arranged in a stack within a filter press unit. The plates are normally covered with filter cloth or filter medium that will allow the liquid component to pass through while holding back solid particles. During the process of filtration, a slurry or suspension is typically pumped into a filter press, where pressure is applied that squeezes the liquid component through the filter media, leaving solid particles trapped within the filter cakes. Afterwards, these cake solids are discharged from the filter plates, and the clarified liquid is discharged at the end of a filtration process to have efficient separation and dewatering of the solids from the liquid phase.

Request for a quote

EGESAN PRINTING AND PACKAGING

Turkey

The inquiries leaded by our Sales & Marketing Department are checked by our Graphics & Design department, firstly. After the controlling process, the draft is sent to our Production Department to be printed.

Request for a quote

HIDROKAR HYDRAULIC PRESS MACHINES INDUSTRY

Turkey

Our manufacturing style is user-oriented, and we manufacture in different features, heights, widths,tonnages through our customers' desires and options.

Request for a quote

FROHLICH

Turkey

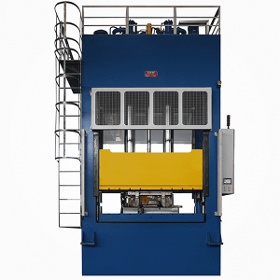

H_Frame Eccentric Presses Between 300-1000 tons.

Request for a quote

HIDROKAR HYDRAULIC PRESS MACHINES INDUSTRY

Turkey

Our manufacturing style is user-oriented, and we manufacture in different features, heights, widths,tonnages our customers' desires and options. The machines and the matarials used in manufacturing process are durable , you can utilize for many years.

Request for a quote

DERYA M.D.M SAN. VE TIC. A.S / GLASSYMOULD®

Turkey

Manufactured out of Special Aluminum Alloy material

Request for a quote

FHM METAL ISLEME

Turkey

We can produce molds in our press machine, taking into account the number of production, and we can prepare the order you want in the dimensions. With our gas metal and teak welds, we can produce quality welds for you.

Request for a quote

MVD MACHINERY

Turkey

Our technologically advanced machines will help you produce efficiently, precisely and quickly. Machines are designed and analyzed with 3-D computer programs, manufactured as welded steel construction, “stress relieved”, precisely machined in moving column CNC machining centers, equipped with world-known parts and presented to the customers use after many stages of quality control processes. Designing and Manufacturing are based on reliability, durability and precision. Machines are easy to use and are built to be ready for user errors. Quality and service support is accepted as principle.

Request for a quote

SONPAR OTOMOTIV SANAYI VE TICARET LIMITED SIRKETI

Turkey

We offer Vertical Bale Press Machine made in Turkey with high quality.

Request for a quote

FROHLICH

Turkey

40 - 60 - 80 - 100 - 125 - 150 - 200 - 250 - 300 tons, high quality eccentric presses

Request for a quote

OZKOC HYDRAULIC MACHINE CO.

Turkey

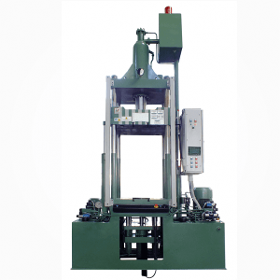

urea, melamine, smc hot hydraulic press

Request for a quote

OZKOC HYDRAULIC MACHINE CO.

Turkey

double action conventional hydraulic press (top effect)

Request for a quote

OZKOC HYDRAULIC MACHINE CO.

Turkey

Ozkoc started business with mass production of first plastic injection presses in Turkey. In the 1970s, by shifting his knowledge and experience on thermoplastic materials to thermoset materials, Ozkoc started to produce melamine presses. With the experience of this field Ozkoc started produce presses for rubber, bakalite, linings and similar resin based thermosets. Same presses also could be used for different materials thanks to the flexible automation.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

OZKOC HYDRAULIC MACHINE CO.

Turkey

In processes which requires single effect, Ozkoc offers variety of solutions between 70 to 7000 tons with extractors or complicated solutions with mold core in case of need. Please contact our specialists for choosing most suitable Hydraulic Press specifications for your production.

Request for a quote

OZKOC HYDRAULIC MACHINE CO.

Turkey

In case of need for high quantity production with multi deep drawing operations, Ozkoc offers 2 different solutions. Hydraulic Transfer Press Hydraulic Triple Action Press Advantage of triple action to double action press is on one mold and one hydraulic press, material can be deep drawn 2 times in a row without any additional workload. Its most suitable for where height is much bigger than material diameter such as fire extinguishers, car-truck filters and alike.

Request for a quote

OZKOC HYDRAULIC MACHINE CO.

Turkey

For the deep drawing parts which symetrical and deeper than 100 mm, forget about conventional presses. Ozkoc Bottom effective deep drawing presses can provide you faster production with 30% less energy consumption comparing to conventional hydraulic presses. Please dont hesitate to contact our technical speacialist to suggest you the best solution for your production.

Request for a quote

OZKOC HYDRAULIC MACHINE CO.

Turkey

Deep Drawing is the most common tecnique for forming either symetric or asymmetric metal parts. It is a multi-purpose deep drawing method suitable for every structure. The material is held tight between the ram and the blank holder to avoid the formation of wrinkles while the force of the ram pushes the die down to wrap it around the punch. Conventional Deep Drawing Press find use in metal forming, especially in automotive, kitchenware, defense, security and many other sectors. This is the most common tecnique for producing either symetric or asymmetric metal parts. It is a multi-purpose deep drawing method suitable for every structure. In need of pressing speed or cushion adjustment for better product surface , Ozkoc Hydraulic presses have option for speed settings on touch screen via proportional valves. The press automation is PLC supported, and programmed with Siemens S7.1200 software. The press is two push buttons controlled

Request for a quote

OZKOC HYDRAULIC MACHINE CO.

Turkey

Ozkoc started business with mass production of first plastic injection presses in Turkey. In the 1970s, by shifting his knowledge and experience on thermoplastic materials to thermoset materials, Ozkoc started to produce melamine presses. With the experience of this field Ozkoc started produce presses for rubber, bakalite, linings and similar resin based thermosets. Same presses also could be used for different materials thanks to the flexible automation.

Request for a quote

OZKOC HYDRAULIC MACHINE CO.

Turkey

Ballistic composites are the ultimate point of our experience and knowledge on thermoset presses and production systems. product, mould, process, press, automation, hot oil or electric heating or oil or water cooling… whichever model is suitable for you and your product, we can give you the whole system on a turnkey basis. We have a serious place in ballistic composite systems, which is a small and very special market in the world. Our references are proof of that.

Request for a quote

HIDROKAR HYDRAULIC PRESS MACHINES INDUSTRY

Turkey

-150 ton -Table: 700x600 mm -Distance between tables max=600 mm min=200 mm -Maximum working pressure:254 bars (Adjustable) -Cylinder stroke: 400 mm -PLC: Siemens 7''

Request for a quote

OZKOC HYDRAULIC MACHINE CO.

Turkey

double action conventional hydraulic press (top effect)

Request for a quote

YILMAZ MACHINE

Turkey

KP 120 machine is designed and constructed for the hydraulically crimping and correct assembly of aluminum profiles . The machine is semiautomatic and the machining cycle of various units are manual controlled by user who always stays outside of the dangerous area. It is designed through the hydrauliccally crimping system Steel construction of the machine table that is strong and lasting Practically adjustment of the knives according to the shape and height of the profiles Practically adjustment of the cylinder feed and profile stops by means of the milimetricruler The machine is equiped with the pneumatic (for clamps ) and hydraulic (for crimping ) foot pedals for the operation control during the machining cycle Double-acting centering setsquare returns to the home position under the table after crimping Powerfull hydraulic pump with 2 x 5 tons capacity Protection plates made of Polyamide material to prevent being scrathes on the profile surface

Request for a quote

HII

Turkey

Sandwich panel press Sandwich Panel Production Line Our contionuous PUR / PIR sandwich panel production line is already recognized its value by exporting to European country with CE and other major sandwich panel producing companies at domestic and foreign, DMMET, we will keep trying for development in accordance with customer’s needs for the high quality sandwich panels. APPLICATION of the PU-PIR PANEL PRODUCTION LINE This production line is suitable for manufacturing socket type ( wall plate panel ) and lapped type ( roof tile panel ) pu sandwich panels. FLOW CHART Uncoiler - Feeding Guide - Protective Film Coating - Roll Forming Machine - Rolling Conveyer - Steel Pre-Heating - Foaming Machine - Double Belt Pressing Machine - Rolling Conveyer - Auto Fly Cutting To Length - Runout Table - Auto Vacuum Stacker - Auto Packing Machine MAIN TECHNICAL DATAS Production Type : Continuous and automatic production Specification of Metarial : 0.3 - 0.

Request for a quote

RAMAZAN AYCAN SAC VE CELIK ISLEME MERKEZI SAN. VE TIC. A.S.

Turkey

Abkant (Press Brake or Bending Press) machines are a type of bending press. They are used in operations such as metal bending and metal curling. Nowadays, many computer-controlled Abkant machines are available. These machines have accelerated the production in terms of both form utility and time saving. With Abkant curling cylindrical, conical, elliptical and oval shapes can be provided. The length, thickness and type of the material (stainless, aluminum, steel sheet, etc.) to be curled are important in the choice of Akbant machine. Akbant machines have individual molds and specific radiuses for various bending operations. The angle calculation of the sheet while performing bending operation using Abkant machine is a skill that requires expertise. Otherwise, bended lengths may not be at the desired sizes. As Ramazan Aycan Inc., we provide you with bending services with our hydraulic and electro servo Abkant machines.

Request for a quoteResults for

Or press - Import exportNumber of results

29 ProductsCountries

Company type

Category

- Presses, hydraulic (14)

- Metal industrial presses (4)

- Industrial washing facilities (2)

- Filtering equipment and supplies (1)

- Bending - steels and metals (1)

- Assemblies, hydraulic (1)

- Binding - machinery and equipment (1)

- Boilermaking, heavy (1)

- Crimping machines (1)

- Glass manufacturing - machinery and equipment (1)

- Industrial waste management (1)

- Laser - cutting and welding machines (1)

- Motor mechanics - hand tools, non power (1)

- Moulding, rubber - machinery (1)

- Packing and packaging - machinery and equipment (1)

- Press agencies, international (1)