- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- metal sheet part

Results for

Metal sheet part - Import export

PARSMEGA MAKINA

Turkey

Radial scanning machine is used to separate low density substances from high density grain products such as wheat, barley, corn and similar. Separates foreign substances such as dust, sand and small seeds in wheat. Wheat entering the machine from the wheat inlet is filled into the vibro feeder and distributed smoothly across the width of the air duct. Here, in the horizontal aspiration channel, the product is separated from low density materials through its double adjustable wall. The fan of the radial scanning machine is mounted on the main body through bearings. The outer body is made of sheet metal, and the foot part and the outlet nozzle located on the foot part are mounted on the body.

Request for a quote

PARSMEGA MAKINA

Turkey

The air purifies the flour dust mixture from flour dust, traps the flour dust and ensures that clean air is expelled from the chimney. Flour dust captured by specially woven bags returns to the system. Thus, flour loss is prevented. The filter section body is made of 2-6 mm sheet metal and the lower part is a cast iron plate. The transmission and engine parts are located on the cast plate. The gearmotor is mounted on the transmission as a battery. The transmission located in the filter section drives the steel plate arm also located in this section. There is an air suction cup on this steel arm. This air suction cup closes the filter bags on its upper part and located in the pipe section, one by one, at regular intervals (with the help of the transmission movement arm) and sucks the product inside. Meanwhile, the clean air included with the product

Request for a quote

DOGRAR METAL

Turkey

We do not only manufacture simple sheet metal parts, we also support our clients in as many aspects as possible such as finished or semi-finished goods upon the request of our clients. Completing fasteners and fittings, powder coating, anodization, laser marking and silk screen can be given as an example of previous application for our customers.

Request for a quote

NOVELTY STEEL

Turkey

Metal bending is one of the most common metal fabrication operation. The sheet metal bending process involves applying a force to a sheet metal part to change its geometry. This force causes stress on the sheet metal beyond its yield strength and permanent physically deform without breaking or failing. The press brake is a commonly used equipment for sheet metal bending. It works by lowering a mould onto a sheet metal work piece positioned on a die, creating the desired form. Our modern steelwork fabrication shops have computer-aided design and detailing (CAD), which is linked directly to factory floor computer numerically controlled (CNC) machinery, creating a genuine seamless CAD/CAM environment. The accuracy of the computer-generated details being transmitted directly to the CNC machinery increases the quality standards of the production. Novelty Steel has adapted EN 1090-2 standards into its manufacturing processes supervised by experienced quality management team.

Request for a quote

NOVELTY STEEL

Turkey

Metal bending is one of the most common metal fabrication operation. The sheet metal bending process involves applying a force to a sheet metal part to change its geometry. This force causes stress on the sheet metal beyond its yield strength and permanent physically deform without breaking or failing. The press brake is a commonly used equipment for sheet metal bending. It works by lowering a mould onto a sheet metal work piece positioned on a die, creating the desired form. Our modern steelwork fabrication shops have computer-aided design and detailing (CAD), which is linked directly to factory floor computer numerically controlled (CNC) machinery, creating a genuine seamless CAD/CAM environment. The accuracy of the computer-generated details being transmitted directly to the CNC machinery increases the quality standards of the production. Novelty Steel has adapted EN 1090-2 standards into its manufacturing processes supervised by experienced quality management team.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

MCT AUTOMATED SMART STORAGE SYSTEMS, VERTICAL STORAGE,LIFT,CAROUSEL,AS/RS,TDM,TQM,ERP,INDUSTRY4.0,

Turkey

YILDIZ-O GENERAL FEATURES • Fast access to products thanks to its perfect ergonomic structure. • Possibility to store a single product in each compartment. • Thanks to the opening of only the relevant compartment, access to other products is impossible. • The first and only compact machine in the world with a capacity of 2340 compartments. • In the office or in the factory thanks to its compact dimensions of 1.2m x 1.2m It offers ease of use throughout. • Thanks to the different types of compartment height and width, wide product groups can be stored • Cost savings through optimization of existing warehouse capacity. • More productivity with faster product access. • Protection and safety of personnel and stored products. • Barcode reader. • High stock capability with its large interior volume. • Robust sheet steel construction. • Oven painted sheet metal parts. • Password and card user login. • Operating voltage: 230 V / 50Hz. • 21” Touch Monitor and Computer.

Request for a quote

AYAZ AUTOMATIC WELDING MACHINES

Turkey

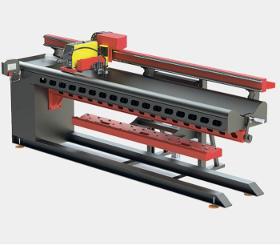

Length Welding Machine is designed for length welding of cylindrical, conical and rectangular bent parts and flat plate sheet metal and plates. Parts between 100-3000 mm diameter can be welded on different machine types. The length welding machine, which offers the ability to make welds internally and externally, is produced from 1 meter to 4 meters long. In some special cases, the length may increase even more. Currently, workpieces with a minimum wall thickness of 0.60 mm can be welded. In submerged arc applications, the wall thickness is up to 20-25 mm. Boilers, water heaters, solar energy boilers, cooling tanks, natural gas chimneys, LPG tubes etc. Length welds of materials are made on this machine. Submerged arc, gas metal, tig etc. Welding systems work synchronously with our machine.

Request for a quote

NOVELTY STEEL

Turkey

Sheet metal fabrication is the process of bending, cutting, punching, assembling sheet metal to form into the desired form. Special tools, such as band saws and chops saws, can also be used in the sheet metal fabrication process. These ensure even cutting throughout the process. Parts are fabricated from a single piece of sheet metal so designs should have a uniform thickness. Although carbon steel is the most prominent material for metal fabrication, stainless steel would be necessary for high corrosive environments whereas aluminium is primarily considered when weight of the product is a major limitation.

Request for a quote

KEDY

Turkey

Introduce the K5200 Sheet Metal Tong & Sheet Lifter from KEDY. The ultimate solution for safe and efficient handling of large sheets of metal. With a maximum load capacity of 20 tons, it can easily handle even the heaviest sheets of metal. Equipped with remote control, it allows the operator to easily extend and retract the arms of the tong from a distance, making it a convenient and efficient tool for handling large sheets of metal. The sheet metal tong is also designed with safety in mind, it has an emergency stop button, programmable memory, auto-grip and overload protection, ensuring that the operator is always in control. It's compact, lightweight and easy to transport, making it ideal for worksites of all sizes. Upgrade your metal handling operation today with the K5200 sheet metal tong and sheet lifter from KEDY. Contact us today to place your order and experience the benefits of the K5200 sheet metal tong and sheet lifter for yourself!

Request for a quote

ERA ALUMINYUM LTD. CO.

Turkey

RAIL LAYER SIZE Long Size SCOPE OF APPLICATION Standing seam roofs Penetration free mounting MODULE ORIENTATION Vertical or horizontal ROOF FASTENINGS A270 stainless screws ERA clips nut L bracket Standing seam clamp

Request for a quote

ERA ALUMINYUM LTD. CO.

Turkey

TECHNICAL SPECIFICATIONS Long Size SCOPE OF APPLICATION Pitched roofs with trapezoidal sheet metal, sandwich panels Connection to concrete & steel beams. MODULE ORIENTATION Vertical or horizontal ROOF FASTENINGS Concrete ans steel screws Epdm rubber A270 stainless screws ERA clips nut Stainless single bracket ERA locknuts.

Request for a quote

ERA ALUMINYUM LTD. CO.

Turkey

TECHNICAL SPECIFICATIONS Long Size SCOPE OF APPLICATION Pitched roofs with trapezoidal sheet metal, sandwich panels Connection to concrete & steel beams. MODULE ORIENTATION Vertical or horizontal ROOF FASTENINGS Concrete ans steel screws Epdm rubber A270 stainless screws ERA clips nut Stainless single bracket ERA locknuts.

Request for a quote

ERA ALUMINYUM LTD. CO.

Turkey

RAIL LAYER SIZE Short & Long Size SCOPE OF APPLICATION Pitched roofs with trapezoidal sheet metal or sandwich panels MODULE ORIENTATION Vertical or horizontal ROOF FASTENINGS Bimetal selftapping screws with sealing washers Epdm rubber A270 stainless screws ERA clips nut Stainless single bracket

Request for a quote

ERA ALUMINYUM LTD. CO.

Turkey

RAIL LAYER SIZE Short & Long Size SCOPE OF APPLICATION Pitched roofs with trapezoidal sheet metal or sandwich panels MODULE ORIENTATION Vertical or horizontal ROOF FASTENINGS Bimetal selftapping screws with sealing washers Epdm rubber A270 stainless screws ERA clips nut Stainless single bracket

Request for a quoteResults for

Metal sheet part - Import exportNumber of results

16 ProductsCountries

Category

- Sheet metals - stamping (5)

- Sheet Metal & Tubes (2)

- Oils, cooking - machinery and equipment (2)

- Industrial sheet metal work (1)

- Forming - steels and metals (1)

- Bending - steels and metals (1)

- Cutting - steels and metals (1)

- Steels and metals - welding and brazing (1)

- Autogenous welding machines (1)

- Lifting equipment (1)

- Storage equipment and systems (1)

- Vertical storage cabinets (1)