- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- metal industrie

Results for

Metal industrie - Import export

FATIH WROUGHT IRON

Turkey

Weight: 17,27 kg Height: 200 cm Width: 100 cm Material: 1.1 mm

Request for a quote

MICRON AMERICA

Turkey

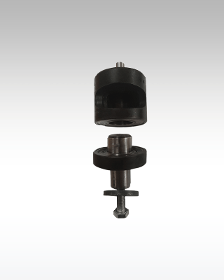

Sheet Metal Grommets quickly and efficiently with Micron’s industrial die sets. These dies are built to cut and set your sheet metal grommets in a 2 step cutting and setting process without having to change your dies to ease the production time. The dies first punches the hole in the material on the first step, then sets the grommet on the second step. This eliminates the need to swap dies or run concurrent machines. √ 3/8 inch smooth top shaft, 3/4 inch smooth bottom shaft. √ Compatible with the MC 20 fastener attaching machine, intended only for sheet metal grommets. √ These dies are compatible with Stimpson and Scovill grommets.

Request for a quote

MICRON AMERICA

Turkey

Sheet Metal Grommets quickly and efficiently with Micron’s industrial die sets. These dies are built to cut and set your sheet metal grommets in a 2 step cutting and setting process without having to change your dies to ease the production time. The die first punches the hole in the material on the first step, then sets the grommet on the second step. This eliminates the need to swap dies or run concurrent machines. √ 3/8 inch smooth top shaft, 3/4 inch smooth bottom shaft. √ Compatible with the MC 20 fastener attaching machine, intended only for sheet metal grommets. √ These dies are compatible with Stimpson and Scovill grommets.

Request for a quote

NOVELTY STEEL

Turkey

Plasma cutting operates by firing an electrically ionised heated gas (plasma) out of a nozzle at a high speed towards the metal. This will form an electrical ark within the gas. High level of heat is generated as electricity from the nozzle travels down this plasma. This heat melts the metal where cutting is achieved. Plasma cutters can cut stainless steel, aluminium, brass and copper along with mild steel. It’s particularly ideal for thick metal, up to 50 mm. If cutting highly reflective or very thick sheets of metal is required, plasma should be the ideal cutting method. Our modern steelwork fabrication shops have computer-aided design and detailing (CAD), which is linked directly to factory floor computer numerically controlled (CNC) machinery, creating a genuine seamless CAD/CAM environment. Novelty Steel has adapted EN 1090-2 standards into its manufacturing processes supervised by experienced quality management team.

Request for a quote

NOVELTY STEEL

Turkey

Sheet metal fabrication is the process of bending, cutting, punching, assembling sheet metal to form into the desired form. Special tools, such as band saws and chops saws, can also be used in the sheet metal fabrication process. These ensure even cutting throughout the process. Parts are fabricated from a single piece of sheet metal so designs should have a uniform thickness. Although carbon steel is the most prominent material for metal fabrication, stainless steel would be necessary for high corrosive environments whereas aluminium is primarily considered when weight of the product is a major limitation.

Request for a quote

NOVELTY STEEL

Turkey

Metal Brackets are used as support elements for structural stability and load bearing capacity. * Angle Brackets * Flat Brackets * U Shaped Brackets * Z Brackets * T Brackets * Custom Brackets

Request for a quote

NOVELTY STEEL

Turkey

Novelty Steel is an experienced fabricator of structural steel fabrications for plant constructions such as Bulk Handling Equipment, HRSG plants, Steel and Wood Industries. Some examples of the fabrications are: Steel Silos and tanks Inlet Ducts and Silencers Stair Towers Bunkers and Hoppers Pipe Supports Exhaust Stacks Our modern steelwork fabrication shops have computer-aided design and detailing (CAD), which is linked directly to factory floor computer numerically controlled (CNC) machinery, creating a genuine seamless CAD/CAM environment. The accuracy of the computer-generated details being transmitted directly to the CNC machinery increases the quality standards of the production. Novelty Steel has adapted EN 1090-2 standards into its manufacturing processes supervised by experienced quality management team.

Request for a quote

NOVELTY STEEL

Turkey

Sheet metal fabrication is the process of bending, cutting, punching, assembling sheet metal to form into the desired form. Special tools, such as band saws and chops saws, can also be used in the sheet metal fabrication process. These ensure even cutting throughout the process. Parts are fabricated from a single piece of sheet metal so designs should have a uniform thickness. Although carbon steel is the most prominent material for metal fabrication, stainless steel would be necessary for high corrosive environments whereas aluminium is primarily considered when weight of the product is a major limitation.

Request for a quote

TEKNIK KONTEYNER - WASTE BINS

Turkey

Industrial Scavenger Dustpan with detachable metal handle, suitable for industrial use. It is produced in Blue and Green colors.

Request for a quote

ILK IHRACAT AS.

Turkey

In industrial processes, we increase your productivity by keeping products or machines in the required internal climate conditions. According to your needs; We increase your production capacity by rapidly cooling your products, We minimize your losses by providing the desired temperature and humidity balance in your production lines, We contribute to your productivity by maintaining your equipment. Get A Quote Email your requirements to info@steeling.net and open the doors to the Turkish metal industry.

Request for a quote

ILK IHRACAT AS.

Turkey

The cabinet that protects the air generating systems in facilities is called the Compressor Cabinet. It is used in compressors, as in the Generator Cabinet, both for protection and to reduce the sound level. Why is a Compressor Cabinet Necessary? The cabinet is necessary to protect the compressor apparatus and circuits and / or to neutralize the damage of external factors that may occur inside the machine. The cabin not only protects the machine and parts, but also protects the living creatures, tools and equipment in the external environment against the damages that may be caused by dangerous parts such as belts, chains and pulleys on the machine. Is the Compressor Cabin Closed? Yes, but at the same time, there are special ventilation ducts and crenellations for air inlet and outlet. Thus, the system is also prevented from overheating. Get a Quote Now Just send us an e-mail for your needs such as compressor cabinet, collector cabinet, generator cabinet.

Request for a quote

ILK IHRACAT AS.

Turkey

In an electrical network, various switching elements are used to open and close the electrical circuit. These switching elements, which are designed to be used for different purposes, are generally on / off at rated currents, idle are divided into various classes according to their number of mechanical operations and their place of use. Get A Quote Contact us immediately for the most suitable solutions for your needs. Our professional team is ready to provide you with exclusive offers. Steeling.Net carries out partner export activities in the Turkish metal industry. Our partner manufacturers are companies that specialize in sheet and steel processing and have a wide product range.

Request for a quote

CIMES HOME

Turkey

RACK CLAD BUILDING SYSTEMS Rack Clad Building Systems eliminates the roof and exterior siding needs of the warehouse and allows you to install a racking system. It eliminates roof and exterior siding needs and allows you to have a construction free racking system. Building construction is not necessa in advance with Rack Clad Building System. Rack Clad Building Systems does not require construction investment, providing a cost advantage from 18% to 30%. Since the use of columns and beams eliminated with the Rack Clad Building Systems, more space gained. Since the Rack Clad Building Systems are in demounted structure, it can easily be mobilized to another place and assembled. Corridor distances in building-free racking systems can be altered depending on type of loading equipment used. In the Rack Clad Building Systems, concrete is applied on the land/ shelves are xed on it, then exterior su ace is constructed by the facade covering (sandwich panel).

Request for a quote

ILK IHRACAT AS.

Turkey

Shape your parts as desired with our professional machining service. Complete your projects in the best way possible with our precision and quality processing capability. Get a Quote and experience the difference! Our Advantages: Precision Processing: We process your parts with the highest precision to meet your quality standards. Variety of Materials: We have the capability to process various materials like steel, aluminum, cast iron, and more. Customized Solutions: We offer customized machining solutions that align with your technical drawings. Who Are We: Steeling.Net carries out partner marketing activities in the Turkish metal industry. Our partner manufacturers are companies that specialize in sheet and steel processing and have a wide product range.

Request for a quote

SACFORM/AGMLINE

Turkey

Decoiler-Straightener & Servo Feeder Systems are Designed on a Single Chassis to Minimize Space Need at Our Customers Production Facility. These Systems are Convenient for Various Purpose of Work and Desired Projects for The Metal Industry.

Request for a quote

AUROMAK MAKINA

Turkey

It is especially used for cleaning, deburring and degreasing of parts that are too small to be placed in baskets. Parts such as fittings, bolts, nuts and nozzles used in the automotive industry; Coating in the coating industry all the small parts before Unions and fittings parts in hydraulic industry, It is used in the cleaning processes of automat on an darmature parts processed on CNC benches in the metal industry.

Request for a quote

ILK IHRACAT AS.

Turkey

Our CNC bending service covers the following areas: Metal Part Bending: Bending metal sheets to the desired measurements and shapes. Design Compatibility: We offer customized bending services that match your technical drawings. Shaping and bending materials in industrial projects is a crucial step that defines the final design of a product. Through our CNC bending service, we guarantee the success of your projects by precisely and accurately bending metal sheets. Shape Your Projects Now! Bring your metal parts to the desired form with our CNC bending service. Complete your projects in the best way possible with our precision and accurate bending technology. Get a Quote and experience the difference! Who Are We: Steeling.Net carries out partner marketing activities in the Turkish metal industry. Our partner manufacturers are companies that specialize in sheet and steel processing and have a wide product range.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ILK IHRACAT AS.

Turkey

Buen Design is passionate about innovation, universality and creating comfortable innovative products. Buen Design adds to this passion the craftsmanship in its DNA and the agility in the design and production process to offer the aesthetic forms of dreams to the needs. This process is motivated by the goal of creating products that appeal to different tastes and synthesize comfort, aesthetics and ergonomics. Buen has been producing high quality mobile furniture for the projects of chain and boutique brands in the hospitality sector for many years with its attention to detail in design and production. In addition to more than a thousand product types, Buen prepares project-specific design products together with designers in many countries. Who Are We: Steeling.Net carries out partner marketing activities in the Turkish metal industry. Our partner manufacturers are companies that specialize in sheet and steel processing and have a wide product range.

Request for a quote

ILK IHRACAT AS.

Turkey

Gear manufacturing consists of the following basic steps: Material selection: Various materials, such as steel, aluminum, plastic, or others, can be used in gear manufacturing. Material selection is made according to the purpose of the gear. Gear profile design: The gear profile is designed Gear mold production: The gear mold is produced according to the gear profile. Gear production: The gear is produced using the selected method. Gear inspection: The gear is inspected after production. Get a Quote Now Contact us immediately for the most suitable production solutions for your gear needs. Our professional team is ready to provide you with exclusive offers. Who Are We: Steeling.Net carries out partner marketing activities in the Turkish metal industry. Our partner manufacturers are companies that specialize in sheet and steel processing and have a wide product range.

Request for a quote

ILK IHRACAT AS.

Turkey

Shape Your Project with Precision Plasma Cutting Service In industrial design and manufacturing projects, accurate cutting is a cornerstone of success. This is where our plasma cutting service comes into play, offering the ability to shape materials like metal, aluminum, steel, and more with precision. Get a Quote Now! Discover our plasma cutting service that offers the most precise and rapid solution for your projects. Share your needs, and our expert team will provide you with the best solution. For more information, you can visit our Contact page. Who Are We: Steeling.Net carries out partner marketing activities in the Turkish metal industry. Our partner manufacturers are companies that specialize in sheet and steel processing and have a wide product range.

Request for a quote

ILK IHRACAT AS.

Turkey

Ugur Medical® Fume Hoods Ugur Medical Fume Hoods are specialized safety gear made for handling chemicals with a high level of intensity. These products have been ergonomically created to the highest degree possible to satisfy user demands and requirements. This makes it possible for workers to do their jobs easily and effectively. These products are recommended for all businesses that want to work with high-intensity chemicals. Our Fume Hood legs have pingo casters that can withstand floor slopes and are chemically resistant. It is also finished with safety glass that can move vertically and horizontally. Gas connections, it complies with DIN 12898 standards, which is the standard for laboratory taps. Who Are We: Steeling.Net carries out partner marketing activities in the Turkish metal industry. Our partner manufacturers are companies that specialize in sheet and steel processing and have a wide product range.

Request for a quote

BACA MAKINE LTD.

Turkey

Sand casting is one of the oldest and most widely used casting processes in the metal industry. It is a costeffective method for producing metal components in a wide range of sizes and shapes, making it suitable for various industries, including automotive, aerospace, and construction. Sand casting offers several advantages, including the ability to produce large and heavy components, flexibility in design, and relatively low equipment and tooling costs.

Request for a quote

TECHNIC MACHINES

Turkey

Scaffolding making machine line is the machine line, which for production of scaffolded metal boards for construction industry. Scaffolding Machine Line General Units Decoiler Straightener and Feeder Eccentric Press Roll Form Unit Stacking Unit For high speed scaffolding panel production results and for matching with our customers scaffolding panel design, we use continuously scaffolding roll forming machine on our scaffolding machine line. On roll forming unit, station quantity and rollform roller diameters are designed according to our customer’s scaffold board design. The scaffolding roll forming unit will be designed for having the best results. Also our eccentric presses have all necessary capabilities and can do precision work during scaffold production. It will work synchronized with other scaffolding machine line units.

Request for a quote

TECHNIC MACHINES

Turkey

We offer suspended ceiling machine line which can produce the suspended ceiling with different thickness, width range production capacity and can work different raw materials. Also we design our tools for different suspended ceiling tile perforation patterns and panel types. As Lay-In, Clip-In and Lay-On suspended ceiling panels. And also we can produce our suspended ceiling tile production lines as to customer special request with until 2.000 mm width. Suspended Ceiling Machine Main Units – Press Feeding Unit – Perforation Press – Sheet Metal Cutting Unit – Conveyor Unit – Press Feeding Unit – Press for Notching and Bending So, machine units one by one as decoiler, straightener. servo feeder, press for perforation, cutting unit, conveyor, second straightener and feeder , press for bending and notching.

Request for a quote

TECHNIC MACHINES

Turkey

We provide for our customers different combinations of cable tray roll former machine line. Such as feeding system solutions from coil or sheet or different working parameters for cable tray roll forming machine. And also we produce our cable tray production line with different final cable tray design as to customer's request. With different cable tray width, thickness, height or with different cable tray punching solutions according to our customer’s final cable tray design. Cable Tray Roll Forming Line Units – Cable Tray Press Feeding Unit – Cable Tray Punching Unit – Cable Tray Roll Forming Unit – Cable Tray Cutting Unit – Cable Tray Coupling Unit Solutions for Cable Tray Making Machine Cable Trays have no standard sizes. Sizes can be between 50 – 1200 mm width and can be between 25 – 100 mm flange height. - Light Duty Cable Tray Roll Former - Medium Duty Cable Tray Roll Forming Line - Heavy Duty – Cable Tray Production Line

Request for a quote

TECHNIC MACHINES

Turkey

Our sheet metal Perforating machine is feasible for working different raw material. We provide necessary adjustments on our perforation machine lines according to requested work of our customers for having final perforated sheet results according to our customers or their market demand. Perforated sheet metals is preferred in many different areas and industries. We can say these industries and field such as, electric and electronic, air condition, refrigerator, machinery, automative, filter production, furniture, lighting, shelfs, racks, walking platforms, filers and etc. Perforation Machine Main Units – Press Feeding Unit – Punching Unit – Cutting Unit – Stacking Unit – Recoiling Unit We provide our perforated sheet machine line according to demand of our customers with different perforated sheet working thickness and width etc.

Request for a quote

TECHNIC MACHINES

Turkey

As Technic Machines, we supply all kind of roll forming machines. We have in our portfolio some standard roll former machine lines but also we provide customs solutions for our customers Roll former machine is pretty common machine in metal industry and each work can have small differences because of the local market demand on roll forming shape. We provide exact solution for our customers with different width, thicknesses and shapes of roll forming. We supply for our customers as standard roll form machine, Customs Roll Former Machine Glazed and Step Tile Making Machine Roof Panel Roll Forming Machine Trapezoidal Sheet Roll Forming Machine Corrugated Sheet Roll Forming Machine Rolling Shutter Roll Former Machine Drywall and Gypsum Channel Making Machine Just contact with us for your other roll forming machine request, we will provide customs solution according to your roll former machine research.

Request for a quote

BOSPORAS

Turkey

The design and manufacture of this model belongs to Bosporas. AYK - 30000 series hydraulic decoiler models have 30.000 kilograms of weight capacity. Our hydraulic decoiler machines work on 1000 – 1300 – 1600 mm of coil width and thanks to hydraulic system, releasing and tightening features can be done automatically. If the grip and tightening process can’t be done according to the inner diameter of the coil manually, hydraulic engine mandrel systems can be used. Hydraulic system provides convenience and advantages when loading and unloading the coils for the companies by making the inner grip as tight as possible while holding the mandrel. The hydraulic coil car that is used in the process of loading and unloading the coils provides advantages like fast loading/unloading and convenience. Hydraulic coil car is an optional feature. Thanks to the circular Mandrels we used in our decoilers, the coils can be decoiled without any defect or fracture.

Request for a quote

BOSPORAS

Turkey

Our AYK 750 model is manufactured to have 30 – 300 mm of coil width and maximum 3 mm of coil thickness. It has 750 kilograms of coil carrying capacity and an inner tightening engine with conical mandrel tightening. Loop control proximity sensor has speed control and pneumatic upper arm has automation. This model is motorized, including motor reducer to transfer power to mandrel.

Request for a quoteResults for

Metal industrie - Import exportNumber of results

68 ProductsCountries

Company type

Category

- Industrial sheet metal work (22)

- Metal industrial presses (20)

- Cutting - steels and metals (2)

- Industrial washing facilities (2)

- Boxes and trays, storage (2)

- Casting, steel (2)

- Mechanical surface treatment - machinery (2)

- Turning - steels and metals (1)

- Bending - steels and metals (1)

- Assemblies, hydraulic (1)

- Bicycle components and parts (1)

- Cabinets and cupboards (1)

- Casting of special and high-grade steels (1)

- Chemicals - Basic Products & Derivatives (1)

- Connectors, pneumatic (1)

- Coupling screws (1)

- Couplings, mechanical (1)

- Dosing pumps (1)

- Dustbins, waste bins (1)

- Furniture - restaurants, bars and cafés (1)