- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- metal bending

Results for

Metal bending - Import export

NOVELTY STEEL

Turkey

Metal bending is one of the most common metal fabrication operation. The sheet metal bending process involves applying a force to a sheet metal part to change its geometry. This force causes stress on the sheet metal beyond its yield strength and permanent physically deform without breaking or failing. The press brake is a commonly used equipment for sheet metal bending. It works by lowering a mould onto a sheet metal work piece positioned on a die, creating the desired form. Our modern steelwork fabrication shops have computer-aided design and detailing (CAD), which is linked directly to factory floor computer numerically controlled (CNC) machinery, creating a genuine seamless CAD/CAM environment. The accuracy of the computer-generated details being transmitted directly to the CNC machinery increases the quality standards of the production. Novelty Steel has adapted EN 1090-2 standards into its manufacturing processes supervised by experienced quality management team.

Request for a quote

NOVELTY STEEL

Turkey

Metal bending is one of the most common metal fabrication operation. The sheet metal bending process involves applying a force to a sheet metal part to change its geometry. This force causes stress on the sheet metal beyond its yield strength and permanent physically deform without breaking or failing. The press brake is a commonly used equipment for sheet metal bending. It works by lowering a mould onto a sheet metal work piece positioned on a die, creating the desired form. Our modern steelwork fabrication shops have computer-aided design and detailing (CAD), which is linked directly to factory floor computer numerically controlled (CNC) machinery, creating a genuine seamless CAD/CAM environment. The accuracy of the computer-generated details being transmitted directly to the CNC machinery increases the quality standards of the production. Novelty Steel has adapted EN 1090-2 standards into its manufacturing processes supervised by experienced quality management team.

Request for a quote

BASAK LAZER

Turkey

We can shape metal materials with our press brake machine with a capacity of 380 tons. We can shape your aluminum, stainless steel and ST series metal sheets in the desired form.

Request for a quote

RAMAZAN AYCAN SAC VE CELIK ISLEME MERKEZI SAN. VE TIC. A.S.

Turkey

Made on customer demand, they can be produced in different sizes and according to certain quality standards.

Request for a quote

HTMACH - HT GRUP MAKINA A.S.

Turkey

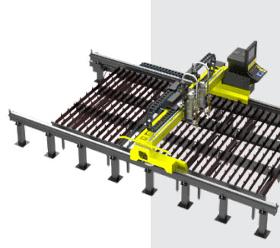

The machine frame is manufactured with advanced technology with very precise tolerances and stress relieved with large welded components. All tensile points are designed with large radii and strain accumulation and possible welding cracks are eliminated. All of the components and materials on the machine are world wide known brand names. The machine has got heavy duty construction and works smoothly with energy saver. We produce from 1360mmX60ton until 61250mmX1250ton as a standard.

ILK IHRACAT AS.

Turkey

Our CNC bending service covers the following areas: Metal Part Bending: Bending metal sheets to the desired measurements and shapes. Design Compatibility: We offer customized bending services that match your technical drawings. Shaping and bending materials in industrial projects is a crucial step that defines the final design of a product. Through our CNC bending service, we guarantee the success of your projects by precisely and accurately bending metal sheets. Shape Your Projects Now! Bring your metal parts to the desired form with our CNC bending service. Complete your projects in the best way possible with our precision and accurate bending technology. Get a Quote and experience the difference! Who Are We: Steeling.Net carries out partner marketing activities in the Turkish metal industry. Our partner manufacturers are companies that specialize in sheet and steel processing and have a wide product range.

Request for a quote

ATOM KARINCA LASER

Turkey

CUTTING CAPACITY 300 mm Mild Steel 50 mm Stainless Steel 50 mm Aluminum plasma cutting We provide high-quality results in cutting various thicknesses of mild steel, stainless steel, and aluminum materials. We also provide beveling up to 45 degrees and marking.

Request for a quote

ATOM KARINCA LASER

Turkey

With our four-roll cylinder bending machines, we can perform cylinder bending for parts that are 3 meters in length, 150mm to 600 mm in diameter. And maximum thickness is 15 mm.

Request for a quote

ATOM KARINCA LASER

Turkey

We produce our customers orders with a 60-meterlong automatic conveyor line and 8x3x2.5 meters electrostatic powder coating box. ATOM KARINCA completely fulfills all the necessary processes and offer perfect surface quality. We perform electrostatic powder coating according to RAL color codes and surface types. Our heat box unit temperature is between 180-200 Celsius So, painted surface that becomes an integral part of the metal part. After final inspections, the materials are checked in the quality control unit, packaged (DIN standard), and then shipped to the customer.

Request for a quote

ATOM KARINCA LASER

Turkey

It can quickly weld stainless steel and mild steel materials even for high-volume orders. In addition to robotic welding, we professionally perform TIG welding for stainless steel and aluminum by our certified welding team. We provide different welding procedures, i.e. MIG, TIG and spot welding.

Request for a quote

ATOM KARINCA LASER

Turkey

ATOM KARINCA can do even the most complex sheet bending operations with the high-tech CNC bending machines and experienced team. We can perform bends with a precision of 0.20 degrees on 3 meters long pieces. Thanks to the station bending capability of our AMADA bending machines, we can produce high-quality parts with repeatable precision.

Request for a quote

ATOM KARINCA LASER

Turkey

Efficient material utilization in production. Fast cutting for cost-effectiveness in production. Cost reduction through minimal waste rates. Economical production from sheet materials compared to machining. High precision due to the machine’s stable construction and modern control and measurement technology (accuracy in all dimensions 0.01 mm). Drilling hole diameter is up to 0.4 mm of sheet thickness Marking can be done on the work pieces. No burrs or heat deformations on cutting surfaces. More flexible design possibilities.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

NOVELTY STEEL

Turkey

Novelty Steel is a contract fabricator of bespoke structural steel works comprising metal cutting, bending, machining, welding and painting. Our modern steelwork fabrication shops have computer-aided design and detailing (CAD), which is linked directly to factory floor computer numerically controlled (CNC) machinery, creating a genuine seamless CAD/CAM environment. The accuracy of the computer-generated details being transmitted directly to the CNC machinery increases the quality standards of the production. Novelty Steel has adapted EN 1090-2 standards into its manufacturing processes supervised by experienced quality management team.

Request for a quote

BASAK LAZER

Turkey

Abkant Twisting is a manufacturing equipment used in sheet metal forming, which can bend the sheet metal raw material and put it into the desired form. Abkant Twisting takes shape by pressing between two molds, and the molds used may vary according to the customer's request and may increase or decrease in this variability. Advantages of Abkant Twisting More than one bending can be produced in succession with Press Brake Twisting Manual and fast stop settings Twisting speed can be adjusted Entering the desired dimensions on the panel

Request for a quote

NEDEX KIMYA SAN VE TIC A.S.

Turkey

Aluminium spacers are the first types of spacers manufactured by NEDEX. In order to meet the requirements of various markets, aluminium spacers are produced in many dimensions for insulating glass. Aluminium spacers are made for cut & plug applications, with plastic corner connectors and for machine bending with metallic straight connectors. The thickness of the aluminium materials varies from 0,18 mm for lower thermal conductivity and cost efficiency to 0,35 mm for bendability and strength.There are different sizes of aluminium spacers with a nominal width of 6 mm and 24 mm. The standard lengths of the aluminium spacers are 3 m, 5 m and 6 m. Other lengths are optional on request. Name, date and imprint are available. In addition, if required, NEDEX can produce colored spacers in many colors using powder coating technology. A minimum of oil is required for chemicals to adhere better to aluminium spacers. The production of spacers is fone with the latest roll formin

Request for a quote

DEHA REKLAMCILIK SAN. VE TIC. LTD. STI.

Turkey

We are manufacturing your custom metal products. We cut, bend and weld metal sheets, profiles pipes in all sizes. Also, we offer PPC coating application in our large capacity factory.

Request for a quote

AVERA TUBE AND PROFILE BENDING AND FORMING

Turkey

seat frame references

Request for a quote

AVERA TUBE AND PROFILE BENDING AND FORMING

Turkey

pipe end blowing and similar process

Request for a quote

AVERA TUBE AND PROFILE BENDING AND FORMING

Turkey

tractors cab and cabın body references

Request for a quote

AVERA TUBE AND PROFILE BENDING AND FORMING

Turkey

body structures frame and bended products

Request for a quote

AVERA TUBE AND PROFILE BENDING AND FORMING

Turkey

body structures frame and bending

Request for a quote

AVERA TUBE AND PROFILE BENDING AND FORMING

Turkey

automotive tube bend and processing

Request for a quote

AVERA TUBE AND PROFILE BENDING AND FORMING

Turkey

seat frame references

Request for a quote

AVERA TUBE AND PROFILE BENDING AND FORMING

Turkey

Tube bended products

Request for a quoteResults for

Metal bending - Import exportNumber of results

44 ProductsCountries

Company type

Category

- Bending - steels and metals (36)

- Bending machine tools (4)

- Industrial sheet metal work (4)

- Laser - cutting and welding machines (2)

- Cutting - steels and metals (1)

- Welding work - steels and metal (1)

- Forming - steels and metals (1)

- Metal structural work (1)

- Steels and metals - forming and cutting (1)

- Double glazing (1)