- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- material optimization

Results for

Material optimization - Import export

DOGRAR METAL

Turkey

Our machines with 1500x3000 mm and 2000*4000 mm capacities can process 0.5 - 20 mm stainless steel, S235 JR and aluminium and 0,5 - 8 mm copper, brass and titanium at high speed. No matter whether manufacturing low quantities or mass production, we are guaranteeing ISO 9001:2015 quality level and the best raw material optimization, thanks to powerfull TRUMPF machinery since 2004. The determining factor in quality and efficiency is the machine as a complete system of laser power and functions. That's exactly why you can’t produce a good part without good technology, and we always adopt the principle of production with the best technology. At the same time, with the automatic loading units we have, we can place the raw material in the machine without damaging the surface quality, and we can save a lot of time in this process compared to the traditional loading method.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

Pre-screening feeders are specialized equipment used in various industries to separate and classify materials before they enter the primary processing machinery. These feeders are designed with screening mechanisms that allow them to filter out oversized or unwanted materials, ensuring that only the desired particle sizes reach the next stage of the process. By pre-screening the feed material, these feeders help optimize the efficiency of the processing system, prevent damage to downstream equipment, and improve overall productivity. The operation of pre-screening feeders involves passing the raw material through a screen or grizzly mechanism that separates it into different size fractions. Larger materials that exceed the predetermined size limit are redirected away from the main flow, while smaller materials pass through the screen and continue along the feeding pathway.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

A Telescopic Radial Conveyor Belt Radial Stacker is a specialized equipment used in material handling applications to efficiently stack bulk materials in radial patterns. This equipment combines the functionalities of a telescopic conveyor belt and a radial stacker to offer enhanced flexibility and efficiency in material stacking operations. The telescopic feature allows the conveyor belt to extend or retract, enabling it to reach varying distances for stacking materials, while the radial stacking capability enables the creation of organized radial stockpiles of bulk materials. By integrating telescopic and radial functionalities, this equipment optimizes material stacking processes and enhances storage capacity within a limited space footprint. The operational principle of a Telescopic Radial Conveyor Belt Radial Stacker involves extending the telescopic conveyor belt to reach the desired stacking location and efficiently conveying materials to create radial stockpiles.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

Pre-screening feeders are specialized equipment used in various industries to separate and classify materials before they enter the primary processing machinery. These feeders are designed with screening mechanisms that allow them to filter out oversized or unwanted materials, ensuring that only the desired particle sizes reach the next stage of the process. By pre-screening the feed material, these feeders help optimize the efficiency of the processing system, prevent damage to downstream equipment, and improve overall productivity. The operation of pre-screening feeders involves passing the raw material through a screen or grizzly mechanism that separates it into different size fractions. Larger materials that exceed the predetermined size limit are redirected away from the main flow, while smaller materials pass through the screen and continue along the feeding pathway. This pre-screening process is crucial in industries such as mining, construction, and recycling

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

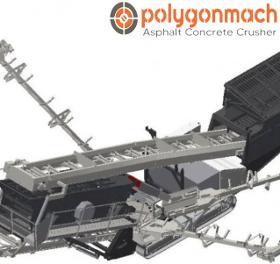

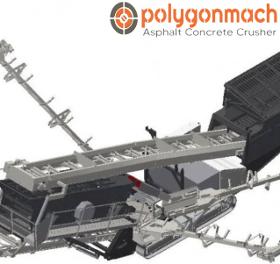

Technical Specifications of Our Track Mounted Impact Crusher Our track mounted impact crusher is meticulously designed to deliver outstanding performance and efficiency in diverse crushing applications. It features a powerful capacity range of 120 - 250 t/h, allowing for high throughput and productivity. The crusher's opening size of 1,050 x 820 mm ensures optimal material intake, while the rotor size of 1100 x 1000 mm guarantees efficient crushing and superior output quality. Weighing in at 47,000 kg, this crusher is built to handle demanding conditions with ease, reflecting its robust construction and durability. High Capacity and Optimal Performance With a crushing capacity of 120 - 250 t/h, our track mounted impact crusher is engineered for high productivity and efficiency. This significant capacity allows you to process large volumes of material quickly and efficiently, making it ideal for extensive projects.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

A Telescopic Radial Conveyor Belt Radial Stacker is a specialized equipment used in material handling applications to efficiently stack bulk materials in radial patterns. This equipment combines the functionalities of a telescopic conveyor belt and a radial stacker to offer enhanced flexibility and efficiency in material stacking operations. The telescopic feature allows the conveyor belt to extend or retract, enabling it to reach varying distances for stacking materials, while the radial stacking capability enables the creation of organized radial stockpiles of bulk materials. By integrating telescopic and radial functionalities, this equipment optimizes material stacking processes and enhances storage capacity within a limited space footprint. The operational principle of a Telescopic Radial Conveyor Belt Radial Stacker involves extending the telescopic conveyor belt to reach the desired stacking location and efficiently conveying materials to create radial stockpiles.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

Advanced Technology of Our Track Cone Crusher PTK156 Our track cone crusher PTK156 is designed to deliver top-notch performance and efficiency in various crushing applications. It features a hybrid drive system that combines the reliability of Volvo, Cummins, and Perkins Tier 3-4 engines. This advanced hybrid technology ensures lower fuel consumption and reduced emissions, making the PTK156 an eco-friendly and cost-effective solution. With a top deck size of 5,000 x 1,500 mm and a bottom deck size of 5,000 x 1,400 mm, the crusher offers substantial screening area for optimal material processing. Weighing in at 34,500 kg, it is robust and durable, built to handle the toughest conditions. Powerful and Efficient Hybrid Drive System The PTK156 track cone crusher is equipped with a hybrid drive system, integrating the power and efficiency of Volvo, Cummins, and Perkins Tier 3-4 engines.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

Model PTV900 VSI Crusher: Unmatched Performance and Efficiency Our Model PTV900 VSI Crusher is engineered to deliver outstanding performance and efficiency in a wide range of applications. Equipped with an advanced rotor type that is closed at 900 mm or opsided at 1,000 mm, this VSI crusher ensures optimal material crushing and high-quality output. The crusher can handle a maximum feed size of 50-80 mm, making it suitable for processing a variety of materials. With a robust weight of 43,000 kg, this crusher is built to withstand demanding conditions and deliver consistent performance across different projects. Advanced Rotor Design for Superior Crushing The PTV900 VSI Crusher features a state-of-the-art rotor design that enhances its crushing capabilities. The closed rotor with a diameter of 900 mm or the optional opsided rotor at 1,000 mm provides flexibility for different crushing applications.

Request for a quote

ILK IHRACAT AS.

Turkey

At steeling.net, we manufacture high-performance screens for stone crushing and recycling machines, designed to meet the rigorous demands of these applications. Utilizing advanced laser cutting, CNC bending, and precise welding techniques, our screens ensure superior durability and efficiency. Perfect for various crushing and recycling operations, these screens are engineered to provide optimal material separation and sizing. Each screen is custom-made to fit specific machine types and requirements, ensuring seamless integration and maximum productivity. Constructed from robust materials, our screens are built to withstand the harshest conditions, offering long-lasting performance and reliability. Trust steeling.net for durable and efficient screens that enhance the effectiveness of your stone crushing and recycling processes.

Request for a quote

ILK IHRACAT AS.

Turkey

At steeling.net, we manufacture superior troughs and screws, designed to optimize your material handling processes. Leveraging advanced laser cutting, CNC bending, and welding techniques, our products ensure precision and durability. Our troughs and screws are ideal for various applications, including agricultural, industrial, and manufacturing environments. Engineered for efficiency, they facilitate smooth and reliable material transport, reducing downtime and enhancing productivity. Each product is custom-made to meet your specific needs, ensuring perfect compatibility with your existing systems. Constructed from high-quality materials, our troughs and screws are built to withstand demanding conditions, providing long-lasting performance. Trust steeling.net for high-performance troughs and screws that improve the efficiency and reliability of your operations.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

Our advanced track mounted screen plant is designed to deliver exceptional performance in various screening applications. Featuring three triple screen decks with a screen size of 5,200 x 1,870 mm, it ensures optimal material separation and high productivity. The plant weighs 36,500 kg, reflecting its robust construction. Driven by a hybrid system with motors from Perkins, Cummins, or Volvo, it offers the flexibility of operating on electricity or diesel. The screen angle is adjustable between 12-18 degrees, allowing for versatile screening tasks tailored to different materials and project requirements.The triple screen decks of our track mounted screen plant provide superior screening capabilities, handling large volumes of material with ease. Each deck is meticulously designed to ensure efficient and accurate separation, enhancing overall productivity.The expansive screen size of 5,200 x 1,870 mm allows for substantial screening area, making it ideal for a wide range of applications,

Request for a quote

TEKNOFOAM AKUSTIK IZOLASYON SANAYI VE TICARET LIMITED SIRKETI

Turkey

3D acoustic wall panels are three-dimensional panels designed for sound insulation and echo control. These panels are made from an acoustically optimized material and are available in a variety of sizes and shapes. Usually, these panels are installed on walls and provide effective soundproofing in any room. 3D acoustic wall panels come with interesting shapes and patterns. This adds an aesthetic touch to any room and makes your decoration look more modern and stylish. 3D acoustic panels are available in different colors and sizes. This allows the panels to fit many different decorating styles.

Request for a quote

NOVOSIM

Turkey

Experience Sound Excellence: Explore our Reverberation Rooms for precise acoustic absorption measurements. Acoustic Testing Perfection: Dive into our Reverberation Rooms to assess material absorption capabilities. Optimize Acoustic Performance: Discover our Reverberation Rooms for unparalleled sound evaluation.

Request for a quote

LASER ISSE LASER TECHNOLOGIES

Turkey

Clean and high-quality cutting edge Increased productivity through reduced scrap and labor costs Low cost maintenance and consumables Maximum system flexibility thanks to robot mobility Designed to run without human intervention Easy and efficient to program, even complex paths and shapes Provides better precision, customization, speed and safety Optimal material utilization Robotic Cutting Software; Parameters automatically adjusted regarding to material and thickness. Calculated tool-paths and robot movements can be verified with simulation. Robot paths and laser parameters can be easily calculated on the offline CAM and simulation software. Step data can be loaded, and paths can be determined from edges or faces of CAD data

Request for a quote

LASPARSAN COMPANY

Turkey

LPS EMK 60 PRO is a machine designed for various applications such as rough plastering works, thermal insulation mortar, perlite, cement mortar, coating materials, and other spraying, injection, and transportation processes. Its technological structure significantly enhances application efficiency and quality. The machine's design features minimized dimensions, facilitating easy transport in the field. The accessory structure is minimized and manufactured using top-tier technology. With its accessories designed for long-term durability under suitable operating conditions, it effectively minimizes material costs to the most optimal levels.

Request for a quoteResults for

Material optimization - Import exportNumber of results

16 ProductsCountries

Company type

Category

- Concrete preparing - machinery and equipment (6)

- Crushing and grinding machinery (2)

- Additives, cement and mortar (1)

- Cement-making - machinery and equipment (1)

- Conveyor belts (1)

- Metal screens for reinforced concrete (1)

- Screws (1)

- Sound insulation materials (1)

- Steels and metals - welding and brazing (1)

- Testing equipment (1)

- Troughs and feeders (1)

- Welding robots (1)