- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- welding constructions

Results for

Welding constructions - Import export

BASAK LAZER

Turkey

We offer welded construction solutions using gas metal arc, argon, MIG, TIG and Laser welding technology according to the requirements of our customers. Welding is the process of joining two or more materials with the effect of heat and/or pressure, with or without the use of additional materials. In addition to the joining process, the welding process is used in coating and filling processes. Today, there are many different welding methods. It is a type of process that is used extensively in the industry. Welded manufacturing is defined as a special process in international standards. For this reason, there are international standards in order to guarantee and level the quality level in welded manufacturing.

Request for a quote

BACA MAKINE LTD.

Turkey

Welded components are all manufactured according to ISO standards.

Request for a quote

SIMER SAC METAL SHEET PROCESSING & FORKLIFT

Turkey

construction material

Request for a quote

ROBINSON CO.

Turkey

This hammer mill grinds easily raw materials which are dry and lle dampens fine. For this reason it is used in food industry.The body is of steel and weld construction. The hammers are on the rotor which turn a mill. The rotormill turns in the strong ball thrust. The hammers are made of hardened steel.It is designed turn free.The sieve is on the hammer mill and it is changed easily without stopping the rotor. Motor is connected directly to the coupling. The body of hammer mill is mounted on the same chassis. Applications Fields ◾ Food industry ◾ Flour and semolina mills ◾ Feed mills ◾ Grain cleaning plants ◾ Corn processing plants ◾ Grain warehouses and silos ◾ Malt Factories

Request for a quote

WORLDWIDE MACHINING SPARE PARTS

Turkey

The joining process on metal or plexi surfaces is expressed as welding construction. Combining different materials by using pressure or heat or using more than one material or giving the impression of being a single piece creates the waist collections of parts and

Request for a quote

MICRON AMERICA

Turkey

Osborne arch punches are forged in one piece from the finest special carbon steel in sizes from 1/8” to 21/8” diameter. Larger sizes are made with our properly engineered two piece welded construction. A unique feature of the Osborne arch punch is the inside taper which permits the punchings to clear easily through the barrel. Punches have fully polished barrel. The cutting edge is fully hardened all the way through and properly finished to provide long use trouble free punching. Original and correct design for cutting. Meet government standards.

Request for a quote

MICRON AMERICA

Turkey

Osborne arch punches are forged in one piece from the finest special carbon steel in sizes from 1/8” to 21/8” diameter. Larger sizes are made with our properly engineered two piece welded construction. A unique feature of the Osborne arch punch is the inside taper which permits the punchings to clear easily through the barrel. Punches have fully polished barrel. The cutting edge is fully hardened all the way through and properly finished to provide long use trouble free punching. Original and correct design for cutting. Meet government standards.

Request for a quote

MICRON AMERICA

Turkey

Osborne arch punches are forged in one piece from the finest special carbon steel in sizes from 1/8” to 21/8” diameter. Larger sizes are made with our properly engineered two piece welded construction. A unique feature of the Osborne arch punch is the inside taper which permits the punchings to clear easily through the barrel. Punches have fully polished barrel. The cutting edge is fully hardened all the way through and properly finished to provide long use trouble free punching. Original and correct design for cutting. Meet government standards.

Request for a quote

MICRON AMERICA

Turkey

Osborne arch punches are forged in one piece from the finest special carbon steel in sizes from 1/8” to 21/8” diameter. Larger sizes are made with our properly engineered two piece welded construction. A unique feature of the Osborne arch punch is the inside taper which permits the punchings to clear easily through the barrel. Punches have fully polished barrel. The cutting edge is fully hardened all the way through and properly finished to provide long use trouble free punching. Original and correct design for cutting. Meet government standards

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

A monoblock welded cement silo, also known under the name of mineral silo, is an industrial storage used for storing cement, minerals, or any other granulated material. These silos are developed as a one-piece, monoblock welded structure so that they are strong, compact, and resistant to environmental factors. Mineral silos perform the ideal function of storing materials in a well-ordered way and also providing maximum security in industries like construction, mining, and manufacture. Normally, the monoblock welded cement silo adopts a sealed construction, which can keep stored materials from rainwater, dust, and other impurities that might affect the quality. The monoblock welded silos come in different sizes and capacities to meet various storage needs.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

A 120-ton Welded Type Cement Silo is a giant container in the shape of cylinder uprightness; it is used in holding cement basically in huge bulk quantities. These are developed out of very steel plates with the welded type, which gives the necessary robustness and strength with respect to the stored material weight on it. The welded design ensures that the silo is air and water-tight, preventing moisture and foreign materials from affecting the quality of the cement. Such silos are typically used in construction projects, where an uninterrupted and reliable supply of the material is to be maintained at all times. Large capacity of 120 tons eases bulk storage of huge quantities of cement at construction sites, eliminating multiple deliveries and hence sustaining an uninterrupted work process. Welded construction further eases their means of installation and maintenance; hence, the silos are best in their simplest and least costly form to meet cement storage needs.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

A 30-ton Welded Type Cement Silo refers to the used specialized storage structure to hold a large quantity of cement in a welded construction. These silos are mainly applied in construction projects, concrete production plants, and industrial projects by which efficient storage and supply of cement are highly required. The welded-type silo design involves welding together the component parts into a robust, seamless storage unit that can bear the weight and pressure of bulk cement. These silos are designed to have a capacity of 30 tons, providing medium storage volume for medium-scale projects that require both a continuous and reliable supply of cement. The application demands regarding cement storing and dispensing are served by a 30-ton welded type cement silo. The welds guarantee the structural integrity of the silo, providing a safe environment for the stored cement.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

A 75-ton welded type cement silo is a huge storage container used in the construction industry for the storage of cement. The silo is composed of panels of welded metal to give it strength and durability in storing large amounts of cement. Here we present the silo with a capacity of 75 tons, providing great storage capacity for cement. Without it, the supply of this critical building material would be very effectively managed on construction sites. The welded construction of the silo not only lends stability to it but also precludes any leakage, thus maintaining the quality of the stored cement inside. This makes the 75-ton welded type cement silo a strong and trustworthy storage facility that forms a key part of building works to ensure continuity in cement supplies for various building projects.

Request for a quote

NERI MAKINA MÜHENDISLIK SANAYI VE TICARET LTD. ŞTI.

Turkey

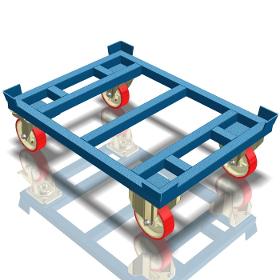

Pallet dolly (Tugger trains) have a robust welded steel construction and are equipped with 4 catch corners. The surface of the trolleys is galvanized or powder-coated, has permanent surface protection and is impact and scratch resistant Swivel and fixed castors: polyurethane tires, hubs with deep groove ball bearings, brakes on the swivel castors, in accordance with the European standard EN 1757-3. Housing galvanized. Standard wheels for medium loads. Quiet running, spring-loaded drawbar.

Request for a quote

NERI MAKINA MÜHENDISLIK SANAYI VE TICARET LTD. ŞTI.

Turkey

Pallet dolly (Tugger trains) have a robust welded steel construction and are equipped with 4 catch corners. The surface of the trolleys is galvanized or powder-coated, has permanent surface protection and is impact and scratch resistant Swivel and fixed castors: polyurethane tires, hubs with deep groove ball bearings, brakes on the swivel castors, in accordance with the European standard EN 1757-3. Housing galvanized. Standard wheels for medium loads. Quiet running, spring-loaded drawbar.

Request for a quote

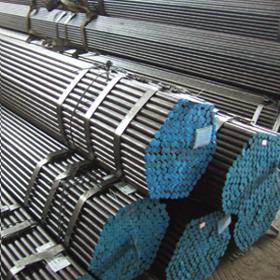

ATTEC ULUSLARARASI DIS TICARET A.S.

Turkey

BOILER TUBES •EN 10216-2 •EN 10216-3 •EN 10217-2 •EN 10217-3 Seamless tubes for pressure purposes EN 10216-2 •unalloyed and alloyed tubes, increased temperature Seamless boiler tubes of this standard have extraordinary temperature and pressure resistance. Due to the production process, a great deal can be offered with regard to purpose-optimized steel qualities. Facts and Figures Diameter (OD)21,0 mm – 610 mm Wall thickness (WT)2,0 mm – 60,0 mm MaterialP195 GH P235 GH, P265 GH, 16Mo3 13CrMo4-5, 25CrMo4 10CrMo9-10 Treatment condition+N TestsTC1 (not including US testing) TC2 (including US testing) VersionsBlack, painted Device pressure standardsAD-2000 W0, AD 2000 W4, PED ATTEC Uluslararasi Dis Ticaret A.S. Barbaros Mah. Mor Sumbul Sk Varyap Meridian I Blok No: 1 Kat:17 D:238 Atasehir 34746 Istanbul/Turkiye Mr.Ahmet Becenoglu Export Marketing Manager Tel: +90 216 488 88 90 – 98 Fax:+90 216 488 98 38 Gsm:+90 532 787 90 89

Request for a quote

ATTEC ULUSLARARASI DIS TICARET A.S.

Turkey

Bright steel EN 10278 The surface is significantly improved due to at least one additional work step – the primary material is beeing drawn, pickled or grinded for this purpose. The bending behaviour can be significantly improved due to additional heat treatment. Facts and Figures Diameter (OD)19,0 mm – 120,0 mm MaterialS235JRC S355J2 C15, C30, C45 other materials upon request Treatment condition+C, +SH, +SL (h7) +QT, annealed TestsUS testing (extra charged) ATTEC Uluslararasi Dis Ticaret A.S. Barbaros Mah. Mor Sumbul Sk Varyap Meridian I Blok No: 1 Kat:17 D:238 Atasehir 34746 Istanbul/Turkiye Mr.Ahmet Becenoglu Export Marketing Manager Tel: +90 216 488 88 90 – 98 Fax:+90 216 488 98 38 Gsm:+90 532 787 90 89

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

HTMACH - HT GRUP MAKINA A.S.

Turkey

Rigidly welded all-steel frame construction Design with "variable-rake" concept Adjustment of machine functions with easy to use CNC control unit Compact, low-maintenance European hydraulics Hydraulic overload protection All of the components and materials on the machine are world wide known brand names. We produce the machine from 3080mmX6mm until 8100mmX10mm

77 TEKNIK MAKINE INSAAT OTOMOTIV

Turkey

CONSTRUCTIVE AND STRUCTURES - Welded Products, - Production of Machine Bodies, Machine Parts and Auxiliary Parts, Spare parts, - Industrial Structures, - Steel Structures, According to customer demands, all kind of design , modelling, analysis and calculation, production, controlling, installation is able to provide by 77 Teknik.

Request for a quoteResults for

Welding constructions - Import exportNumber of results

20 ProductsCountries

Company type

Category

- Punching machine tools (4)

- Concrete preparing - machinery and equipment (3)

- Welding work - steels and metal (2)

- Steels and metals - welding and brazing (1)

- Steel, structural (1)

- Bending - steels and metals (1)

- Cements, special (1)

- Flour milling - machinery and equipment (1)

- Pipes and tubes, stainless steel (1)

- Pipes and tubes, steel (1)

- Shearing machine tools (1)

- Steels and metals - machining (1)

- Transport assistance - wide and long loads (1)

- Wire mesh, welded (1)