- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- transportation- bulk

Results for

Transportation- bulk - Import export

GT SEMI TRAILERS

Turkey

CEMENT TRAILER CEMENT TRAILER also known as silo trailer which is used for carrying different bulk items like cement, flour, wheat, lime and else. This kind of Bulk Cement Trailer has different usage opportunities like tipping silo trailer, or euro type trailer. As GT Semi trailer we offer a wide range of Cement Trailer with different specification and different capacities such as cement trailers; v type cement trailers, stainless cement trailers, aluminum cement trailer.

Request for a quote

PETROGAZ

Turkey

CEMENT TRAILER also known as silo trailer which is used for carrying different bulk items like cement, flour, wheat, lime and else. This kind of Bulk Cement Trailer has different usage opportunities like tipping silo trailer, or euro type trailer. As Petrogaz and Dogan Yildiz we offer a wide range of Cement Trailer with different specification and different capacities such as cement trailers; v type cement trailers, stainless cement trailers, aluminum cement trailer.

BIGBAGSACK

Turkey

National or international transportation of hazardous goods is regulated with UN Recommendations on the Transport of Dangerous Goods which aim to prevent possible accidents and consequent problems as well as to minimize the environmental effects. In order to assure that the UN classified goods are safely transported and stored, we subject our UN Bags to related tests and provide our customers with certificates given by independent international test houses. In respect to UN recommendations, we perform the following 6 tests in our inhouse test laboratory to verify the quality of the said bigbags: Top lift test Drop test Topple test Righting test Stacking test Tear test All approved bigbags have a valid UN certificate and the certificate info is marked visibly on each bigbag.

Request for a quote

BIGBAGSACK

Turkey

Bigbag type which assure that the products picked in their natural environment will keep their freshness and have a long shelf life. As the ventilated parts on the body permit constant air circulation the filled product does not rot and depreciate due to lack of air. Mostly used for Hazelnuts Agricultural products such as potatoes, onions and carrots Timber, wood and other similar forest products

Request for a quote

BIGBAGSACK

Turkey

All products of Antistatig bigbag in 4 groups are produced with certificates obtained from objective test houses recognized by our industry. FIBC – Type A FIBC – Type B FIBC – Type C FIBC – Type D

Request for a quote

BIGBAGSACK

Turkey

Q bags as known in the industry are bigbags which do not bulge on the sides and keep its geometrical shape when filled. This provides a series of advantages to the users. Thanks to the stable and non bulging structure, less space loss on storage Up to 20% extra volume during filling More product delivery in transport which results in proportional freight gain We propose different “baffle” options which provide maximum profitability depending on the application

Request for a quote

BIGBAGSACK

Turkey

In 4 loop big bag production we have a wide range of products which can answer to all special requests of our customers. Our big bags keep various products produced in different industries from humidity, electrostatical hazards and external factors, elongate the shelf life and assure a safe storage and transportation with no loss of quality. While designing and manufacturing our big bags we prioritize safety as well as our customer’s demands and needs. We provide different design options for different industries. Standard big bag types are available for a loading capacity of 100 to 2500 kg and according the EN ISO 21898:2005 regulation can be manufactured as 5:1 (single use), 6:1 (multiple use) or UN (Recommendations on the Transport of Dangerous Goods) in conformity with the certificates issued by reputable international test houses.

Request for a quote

BIGBAGSACK

Turkey

Cost-benefit wise 1 &2 Loop bigbags are the most advantageous bigbag types. While the simple construction facilitates the usage, various fabric widths permit a wide volume range. Its unique design provides the maximum loading capacity at a minimal cost and consequently assures advantages in freight cost as well. This type can be designed both for non-hazardous goods described in EN ISO 21898 and hazardous goods classified as UN. Depending on the handling process, the bigbag can be manufactured either with 1 or 2 lifting loops, with coated or uncoated fabric and with or without liner. The liners can be attached to the outer body in different ways depending on the requirements.

Request for a quote

PARSMEGA MAKINA

Turkey

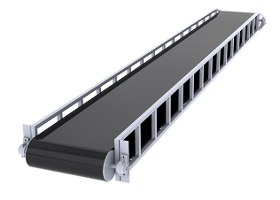

These are conveyors used for general transportation purposes, in the horizontal or inclined transmission of a wide variety of products to different distances. Material transportation in belt conveyors is provided by the belt stretched between the tension drum and the drive drum, which is moved by a motor-reducer system. Belt selection is made according to the type of product to be transported and types such as PVC, polyurethane, rubber and mesh belts can be selected. It is suitable for transporting boxed, bulk and packaged products. It is the conveyor type with the widest usage area, and its usage capacity is also highly variable. Conveyor leg group and chassis are made of Aluminum or electrostatic powder coated steel construction.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

What is a Twin Bucket Chain Elevator? A twin bucket chain elevator can be described as a specially designed vertical conveyor system whereby it can transport bulk materials, such as grains, sand, ore, coal, and others that are granular or in powdered states. Consider this kind of elevator with two parallel chains or belts fitted with a series of buckets running in a continuous loop. In operation, the elevator scoops up material at the lower end with its buckets and transports it to the top for discharge. This mechanism ensures an effective and controlled way of moving large quantities of bulk materials vertically. These elevators find wide applications in industries where bulk material handling is a crucial aspect of the operation, like in agriculture, mining, construction, and manufacturing. This system comes into its own in applications that involve dependable, continuous material flow between various levels in a facility.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

A twin bucket chain elevator can be described as a specially designed vertical conveyor system whereby it can transport bulk materials, such as grains, sand, ore, coal, and others that are granular or in powdered states. Consider this kind of elevator with two parallel chains or belts fitted with a series of buckets running in a continuous loop. In operation, the elevator scoops up material at the lower end with its buckets and transports it to the top for discharge. This mechanism ensures an effective and controlled way of moving large quantities of bulk materials vertically. These elevators find wide applications in industries where bulk material handling is a crucial aspect of the operation, like in agriculture, mining, construction, and manufacturing. This system comes into its own in applications that involve dependable, continuous material flow between various levels in a facility.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

Ship loading and bulk material handling plants: what are they? Plants for handling bulk materials and loading ships are made to load different kinds of bulk materials onto ships quickly and safely. These materials may consist of fertilizers grains ores coal and other goods that are shipped in containers. Conveyor belts hoppers and loading spouts are examples of the specialized machinery used by ship loading plants to move bulk materials from processing or storage areas onto the ships. However a variety of bulk materials can be handled in industrial settings like mines power plants and manufacturing facilities by bulk material handling plants. These facilities store move and process bulk materials in huge quantities using conveyor systems stackers reclaimers and other equipment. The logistics and supply chain management of the industries involved in the transportation of bulk materials depend heavily on the smooth operation of ship loading and bulk material handling facilities.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

Ship loading and bulk material handling plants: what are they? Plants for handling bulk materials and loading ships are made to load different kinds of bulk materials onto ships quickly and safely. These materials may consist of fertilizers grains ores coal and other goods that are shipped in containers. Conveyor belts hoppers and loading spouts are examples of the specialized machinery used by ship loading plants to move bulk materials from processing or storage areas onto the ships. However a variety of bulk materials can be handled in industrial settings like mines power plants and manufacturing facilities by bulk material handling plants. These facilities store move and process bulk materials in huge quantities using conveyor systems stackers reclaimers and other equipment. The logistics and supply chain management of the industries involved in the transportation of bulk materials depend heavily on the smooth operation of ship loading and bulk material handling facilities.

Request for a quote

DONAT TRAILER

Turkey

Milenium Model Silo Trailer with its variety from 28 to 50 cbm made by Donat Trailers engineering and long term experiences. Cement Trailer can design for cement transport, powder transport or granular transport. Width of milenium Semi Trailer can be 2.550 mm. Generally, diesel engine or electric motor compressor used for Cement Silo Trailer for discharge.

Request for a quote

DONAT TRAILER

Turkey

Axles: Cement semi trailer each has 9 tones loading capacity, drum brake, air suspension, Brake System: Double line air brake system, Knorr-Bremse EBS brake system. Capacity: 32cbm Chassis: Made of ST52 steel sheet iron, King-Pin: 2½” removable king pin. Landing Legs: Front legs are mechanic lifter, 24 tones loading capacity. (JOST Brand) Compressor: Turkish brand, air compressor. Tires: 285 / 65 R 22,5 Electric System: 24 V. Electric system in accordance with E.U Standards. Paint: After sand-blasting, cement semi trailer painted double line epoxy coat and double line paint in requested colour is applied.

Request for a quote

UGUR MAKINA CRUSHING & SCREENING

Turkey

Belt conveyors are particularly successful in transporting bulk materials such as mineral ores, stone, sand and grain at high capacities and over long distances. A belt conveyor consists of an endless belt stretched between two drums. Belt conveyors are usually the most suitable solution when stacking material needs to be transported over long distances without stopping. They are used horizontally or with a low slope. The material to be transported can be sand or granule.

Request for a quote

KEDY

Turkey

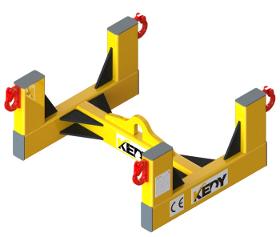

Introducing the KEDY K1300 Big Bag Lifting Beam, the ultimate solution for handling and moving large bulk materials with ease and efficiency! Our KEDY K1300 is specifically designed to handle big bags, the most common and cost-effective containers for storing and transporting dry bulk materials such as grain, sand, and fertilizer. The beam's sturdy frame and secure hooks make it easy to lift and move big bags safely and efficiently, reducing the risk of spills, damage to the bag, or injury to workers. One of the key benefits of the KEDY K1300 is its versatility. It can be used with a wide range of big bag sizes and can be attached to any crane or lifting equipment, making it ideal for use in a variety of industries and applications. So if you're looking for a reliable and efficient solution for handling and moving large bulk materials, look no further than the KEDY K1300 Big Bag Lifting Beam! Order now and start enjoying the benefits of hassle-free big bag handling.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

EMA INDUSTRY ENGINEERING SERVICES CO.

Turkey

EMA intermediate bulk container (IBC) is a large vessel that is used to store fluid and bulk materials or transport them. IBC’s can be manufactured from many different materials such as stainless steel, aluminum, mild steel, and exotic alloys. EMA designes manufactures hundreds of intermediate bulk containers and bins (IBC's) per year. EMA 350 gallon (1325 liter) Intermediate Bulk Container is one of EMA’s most popular IBC’s. EMA's advanced manufacturing technology provides a one-piece body, 10-gauge (.135”/3.4 mm) stainless steel construction and single-seam welding, for greater strength and durability. The features either a center drain or side drain discharge outlet to meet your individual delivery system needs. All tanks are manufactured with sloped bottoms and 2” (5.08 cm) ball valve discharge and safety cap.

Request for a quoteResults for

Transportation- bulk - Import exportNumber of results

19 ProductsCountries

Company type

Category

- Bulk transporters (8)

- Tanker transport - granular and dry bulk (2)

- Concrete preparing - machinery and equipment (2)

- Conveyor belts (1)

- Containers, metal (1)

- Bulk materials for construction (1)

- Container transport systems (1)

- Crushing and grinding machinery (1)

- Lifting equipment (1)

- Oils, cooking - machinery and equipment (1)

- Semitrailers, industrial (1)

- Tar and asphalt - construction materials (1)