- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- punch cutting

Results for

Punch cutting - Import export

MICRON AMERICA

Turkey

The frame is made of highly polished steel and the cutting dies are simply pushed in for easy replacement. Replacement cutting tubes are also available.

Request for a quote

MICRON AMERICA

Turkey

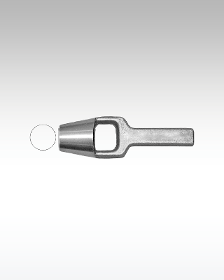

Osborne arch punches are forged in one piece from the finest special carbon steel in sizes from 1/8” to 21/8” diameter. Larger sizes are made with our properly engineered two piece welded construction. A unique feature of the Osborne arch punch is the inside taper which permits the punchings to clear easily through the barrel. Punches have fully polished barrel. The cutting edge is fully hardened all the way through and properly finished to provide long use trouble free punching. Original and correct design for cutting. Meet government standards.

Request for a quote

AHP PLASTIK MAKINA

Turkey

Manual hydraulic cutting punch, 10 Ton force capacity , cutter based on customer request

Request for a quote

MICRON AMERICA

Turkey

Micron hand tools are made of high quality stainless steel material. Remember to use a plastic mallet, not a steel hammer.

Request for a quote

MICRON AMERICA

Turkey

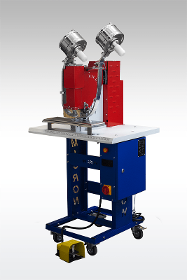

Fully automatic, self loading machine. Fed by hoppers. Punches a hole and sets the grommet in one step. Can only accommodate one size die for the lifetime of the machine. Foot pedal for hand safety. Requires 220 volts of AC power to operate. This machine is built around a newly designed frame that requires less space and is much lighter than previous generations. The M 500 fully automatic machine that feeds both the grommet and washer punches the hole in the material and attaches the grommet and washer, all in a single cycle. This machine has been specifically engineered for light to medium duty applications. Features Flywheel powered and cam actuated to ensure consistent settings. Advanced cutting technology to punch a hole in multi layeredmaterialsCompensator to allow for a nominal variance in material thickness.Stripper plate to lift grommet and washer setting off the pilot ofthe anvil.

Request for a quote

NOVELTY STEEL

Turkey

Sheet metal fabrication is the process of bending, cutting, punching, assembling sheet metal to form into the desired form. Special tools, such as band saws and chops saws, can also be used in the sheet metal fabrication process. These ensure even cutting throughout the process. Parts are fabricated from a single piece of sheet metal so designs should have a uniform thickness. Although carbon steel is the most prominent material for metal fabrication, stainless steel would be necessary for high corrosive environments whereas aluminium is primarily considered when weight of the product is a major limitation.

Request for a quote

NOVELTY STEEL

Turkey

Sheet metal fabrication is the process of bending, cutting, punching, assembling sheet metal to form into the desired form. Special tools, such as band saws and chops saws, can also be used in the sheet metal fabrication process. These ensure even cutting throughout the process. Parts are fabricated from a single piece of sheet metal so designs should have a uniform thickness. Although carbon steel is the most prominent material for metal fabrication, stainless steel would be necessary for high corrosive environments whereas aluminium is primarily considered when weight of the product is a major limitation.

Request for a quote

NOVELTY STEEL

Turkey

Sheet metal fabrication is the process of bending, cutting, punching, assembling sheet metal to form into the desired form. Special tools, such as band saws and chops saws, can also be used in the sheet metal fabrication process. These ensure even cutting throughout the process. Parts are fabricated from a single piece of sheet metal so designs should have a uniform thickness. Although carbon steel is the most prominent material for metal fabrication, stainless steel would be necessary for high corrosive environments whereas aluminium is primarily considered when weight of the product is a major limitation.

Request for a quote

KMC GROUP - MEKO METAL

Turkey

Bending with standard tube and profile bending machines, Cutting and punching operations on all profiles with special templates or if it is necessary by hydraulic or pneumatic machines that can be designed and produced ourselves, Cutting of the profiles done with CNC saws in requested length.

Request for a quote

DEMTE ELEKTRIK METAL SANAYI

Turkey

4 different types of slot cutting Punching Cutting without burr Cutting without Unblunt blade Ruler for easier setting Profile cutting according to customer’s specifications.

Request for a quote

DEMTE ELEKTRIK METAL SANAYI

Turkey

4 different types of slot cutting Punching Cutting without burr Cutting without Unblunt blade Ruler for easier setting Profile cutting according to customer’s specifications.

Request for a quote

TARHAN AUTOMATION AND MACHINE

Turkey

Cutting and Drilling : We produce cutting and punching machines that can perform product-specific cutting and punching of rubber, plastic, aluminum and steel materials, either simultaneously or separately.

Request for a quote

AHP PLASTIK MAKINA

Turkey

A key attribute of plastic is its resistance to environmental stress cracking. It can be tested easily with AHP ESCR tester. According to ASTM D 1693 , digital timer , PID temperature controller, water circulation system, bending tool, brass sample holder , glass tube , sample cutting punch , sample notch press , sample bending tool

Request for a quote

AHP PLASTIK MAKINA

Turkey

A key attribute of plastic is its resistance to environmental stress cracking. It can be tested easily with AHP ESCR tester. According to ASTM D 1693 , digital timer , PID temperature controller, water circulation system, bending tool, brass sample holder , glass tube , sample cutting punch , sample notch press , sample bending tool

Request for a quote

SUPPLYIZI MATTRESS COVER PILLOW MEMORY FOAM LINEN BED

Turkey

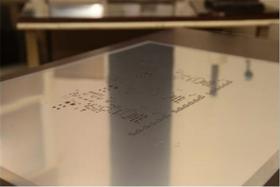

Due to the fact that punching and cutting processes are performed with molds in single-sided printed circuit board production, our company has established its own mold production facility. Printed circuit information from customers is converted into a format suitable for mold production machines in the CAD/CAM work preparation center and transmitted to the mold center via the local computer network. In this center, necessary mold drawings are made using this information, and molds are produced quickly and precisely on state-of-the-art machines.

Request for a quote

MIA MAKINA

Turkey

Mia Engineering Limited performs design, project, and product analysis to turn your projects into the best quality and efficient product with its experience and technological developments since 2009. We work in the fields of CNC machining, CNC turning, CNC milling, CNC laser cutting, CNC Plasma cutting, CNC punch cutting and all kinds of machining with our well-trained expert staff.

Request for a quote

MIA MAKINA

Turkey

Mia Engineering Limited performs design, project, and product analysis to turn your projects into the best quality and efficient product with its experience and technological developments since 2009. We work in the fields of CNC machining, CNC turning, CNC milling, CNC laser cutting, CNC Plasma cutting, CNC punch cutting, and all kinds of machining with our well-trained expert staff.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

YENIMAK MAKINA

Turkey

Maximum Mould Size : 650x435mm Maximum Forming Area : 620x405 mm Maximum Cutting Area : 630x405 mm Negative Forming Depth : 120 mm Maximum Sheet Width : 710 mm Minimum Sheet Width : 300 mm Upper Heater Heating Power : 32.5 kW Lower Heater Heating Power : 32.5 kW Continuous Power Consumption : 40 kW Total İnstalled Power : 80 kW Vacuum : 105 m³/h Dry Running Cycle : 60 cycle/min Weight (approx.) : 7000 kg Length : 7000 mm Width : 2300 mm Height : 2500 mm Required Compressor : 3 m³/min Required Cooler : 20000 kcal/hour

YENIMAK MAKINA

Turkey

Maximum Mould Size : 850x650 mm Maximum Forming Area : 820x620 mm Maximum Cutting Area : 820x620 mm Positive Forming Height : 160 mm Negative Forming Depth : 160 mm Maximum Sheet Width : 910 mm Minimum Sheet Width : 400 mm Upper Heater Heating Power : 71 kW Lower Heater Heating Power : 71 kW Continuous Power Consumption : 142 kW Total İnstalled Power : 225 kW Vacuum : 250 m³/h Dry Running Cycle : 60 cycle/dak Weight (approx.) : 14000 kg Length : 10300 mm Width : 2800 mm Height : 3000 mm Required Compressor : 8 m³/min Required Cooler : 50000 kcal

Results for

Punch cutting - Import exportNumber of results

20 ProductsCountries

Company type

Category

- Punching machine tools (3)

- Testing equipment (3)

- Industrial sheet metal work (2)

- Control boxes - electric (2)

- Steels and metals - machining (2)

- Thermoforming, plastics - machinery (2)

- Stainless steels (1)

- Casting, steel (1)

- Machine tools, cutting - parts and accessories (1)

- Metal structural work (1)

- Rolling scaffolding (1)

- Screen printing on metal (1)