- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- production of machines

Results for

Production of machines - Import export

RT KAUCUK POLIÜRETAN VE MAKINA SAN. TIC. LTD. STI (RT GROUP)

Turkey

Within the Rt Makina Production Facility; With over 10 high-tech CNC benches, it can process complex and sensitive parts that will be manufactured from aluminum, zamak, steel, stainless steel, titanium, magnesium/nickel-based materials in the form of plate, sheet metal, casting and forging in accordance with customer specifications.Machining is a manufacturing method that covers the shaping of the pre-designed and constructed machine element, the manufacturing process of which is determined, by subjecting it to the cutting operation with the specified cutting tools on the machining benches suitable for the manufacturing process.

Request for a quote

DDC TEKNOLOJI VE MAKINA SAN. A.S.

Turkey

Napkin Production Machine is an industrial level machine designed for mass production of napkins. Modern napkin manufacturing machines meet high standards in terms of both quality and efficiency and have a wide range of uses. Napkin Production Machine is an industrial machine used to produce napkins from raw paper material. This machine automatically performs the processes of cutting, folding and sometimes printing the paper. The main purpose of the machine is to meet the demand by producing napkins at high speed and continuously. Fast Production Capacity: Continuous and fast napkin production. Multifunctional Operations: Ability to perform operations such as cutting, folding and printing together. Flexible Production Options: Ability to produce napkins in different sizes and patterns. User Friendly Interface: Easy operation and adjustable functions. Napkin Production Machine is used in places such as napkin producing factories and paper processing plants.

Request for a quote

PARSMEGA MAKINA

Turkey

It ensures that flour and bran-like products coming out of the machines are returned to the factory.

Request for a quote

MICRON AMERICA

Turkey

All dies, sold separately. Its dependability and affordable pricing makes this machine a perfect entry level hand press machine which is ideal for people who don’t use a large variety of fastener products. This machine is a low cost machine perfect for the semi professionals that install snaps, rivets, jean button and self piercing grommets up to size #3.

Request for a quote

DDC TEKNOLOJI VE MAKINA SAN. A.S.

Turkey

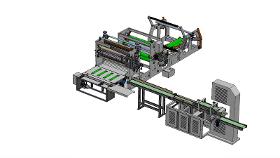

Accumulator, the transfer machine is a device that plays an important role in the production processes of toilet paper and kitchen towel rolls, increasing the efficiency of production lines. This equipment automates the storage, sorting and dispatching of rolls, ensuring that the production process is uninterrupted and orderly. This device which is widely used in modern toilet paper production facilities, significantly increases the efficiency of the production line and product quality. The Roll/Log Accumulator is a device that transfers the produced rolls of toilet paper or kitchen towels to the next unit and regulates the flow in the production process. This accumulator is designed to prevent possible disruptions in the production line and to ensure a continuous production flow. It facilitates the organised processing and packaging of the rolls in the production process and allows the glue to dry before the rolls are cut to the desired size.

Request for a quote

DDC TEKNOLOJI VE MAKINA SAN. A.S.

Turkey

La machine de rembobinage automatique de papier toilette et d'essuie-tout est une machine axée sur l'efficacité et la qualité qui automatise le processus de rembobinage des produits en papier. Cette machine augmente la qualité et la facilité d'utilisation des produits finis en assurant un enroulement précis et régulier du papier toilette et des essuie-tout. Cette machine, qui occupe une place importante dans les installations de production modernes, attire l'attention par sa rapidité et sa capacité de production continue.

Request for a quote

DDC TEKNOLOJI VE MAKINA SAN. A.S.

Turkey

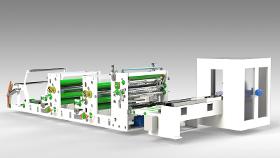

Automatic Mono Toilet Paper and Kitchen Towel Production Line is an efficiency and quality-oriented technology that realises toilet paper and kitchen towel production on a single line. This production line stands out with its high speed and continuous production capability in modern paper production processes. The ability to produce both toilet paper and kitchen towels on a single line simplifies production processes and increases productivity.Automatic Mono Toilet Paper and Kitchen Towel Production Line is a system that can produce both toilet paper and kitchen towels in a single production line. The main feature of this line is that it can produce both products at high quality standards and continuously. In this way, more production can be done in less space. Double Product Production on a Single Line: Both toilet paper and kitchen towel production. High Productivity: Continuous and fast production processes.

Request for a quote

DDC TEKNOLOJI VE MAKINA SAN. A.S.

Turkey

Combining aesthetics and functionality in toilet paper and kitchen roll production, the 5 Embossed Toilet Paper and Kitchen Roll Machine has a technology that gives extra softness and absorbency to paper products. The embossing process increases both, the visual and tactile quality of the product by adding embossed patterns to the paper surface. If high quality and standard are needed for toilet paper and kitchen rolls, this machine is ideal. The Toilet Paper and Kitchen Roll Machine with 5 Embossings is a production machine that adds special embossed patterns to paper products. This machine adds aesthetic and functional reliefs to the surface of toilet paper and kitchen rolls by using special embossing rollers. These embossings increase the paper’s softness and absorbency, thus improving the product quality. High Quality Embossing Process: it gives an aesthetic and tactile superiority to paper products.

Request for a quote

DDC TEKNOLOJI VE MAKINA SAN. A.S.

Turkey

Napkin production is a process that requires precision and quality and an important part of this process is Band Saw Napkin and oll Cutting Machine. This machine increases efficiency and quality in napkin production by making high speed and sharp cuts. Band Saw Napkin Cutting Machine is one of the last stages of the product before reaching the end user, especially by ensuring that the napkins are cut in standard sizes and with smooth edges. Band Saw Napkin Cutting Machine is an industrial machine used to cut large napkin rolls in specified sizes. Using band saw technology, it cuts napkins at high speed and smoothly. This machine is suitable for both plain and patterned napkins and offers high cutting precision. High Cutting Speed and Precision: It performs the cutting process quickly and precisely. Flexible Production Capability: Ability to cut napkins of different sizes and patterns. Durable Structure: It has a robust structure suitable for continuous and intensive use.

Request for a quote

DDC TEKNOLOJI VE MAKINA SAN. A.S.

Turkey

At the present, toilet paper production has become an industry that requires high speed and efficiency. The 2 Channels Log Saw (Toilet Paper Cutting Machine) is a critical part of this process and is an industrial machine with advanced Technology that allows toilet paper rolls (logs) to be cut in standart sizes and with high precision. By making sharp cuts at high speed, this machine significantly increases both the efficiency of the toilet paper production process and product quality. Moreover, its rapid adaptation to ever-changing market demands makes this machine indispensable for toilet paper production facilities. The 2 Channels Log Saw Toilet Paper Cutting Machine is a high capacity industrial machine designed to cut long and continuous toilet paper rolls (logs) according to specified dimensions. The most important feature of this machine is its two-channel structure.

Request for a quote

DDC TEKNOLOJI VE MAKINA SAN. A.S.

Turkey

V-fold dispenser napkins, which are frequently used in modern restaurants, cafes and service sector, are produced with high efficiency and quality standards thanks to these machines. V Fold Dispenser Napkin Machine is a machine that packs paper napkins by folding them in a ‘V’ shape. This special folding method allows the napkins to be used easily in dispenser devices and allows them to be removed individually. The machine makes it possible to produce large quantities of napkins particularly quickly and efficiently. Folding Technique: Folds the napkins in a special 'V' shape. High Production Capacity: Suitable for the production of large quantities of napkins. Flexible Production Options: Ability to process master bobbins of different sizes and thicknesses. User Friendly Interface: Easy operation and adjustable functions

Request for a quote

DDC TEKNOLOJI VE MAKINA SAN. A.S.

Turkey

Z Fold Dispenser Napkin Machine is a machine that packs paper napkins by folding them in ‘Z’ shape and makes them suitable for use in dispensers. This folding method allows the napkins to be removed individually and easily, which provides fast and practical use, especially in busy environments. Z-folded napkins are a preferred option in modern service areas and homes by providing ease of use. Highlights of this machine include the following: Z Folding Technique: Folds napkins in a special 'Z' shape. High Production Capacity: Suitable for the production of large quantities of napkins. Flexible Production Options: Ability to process paper of different sizes and thicknesses. Z Fold Dispenser Napkin Machine is frequently used for the production of napkins suitable for quick service restaurants, cafes, hotels and other service sectors Maintenance of the Z Fold Dispenser Napkin Machine is important to keep the machine running efficiently and smoothly.

Request for a quote

KAYADERELI CONSTRUCTION

Turkey

Its Standard :TS EN 13279 Water / Plaster Ratio: 10 kg gypsum in 5 - 6 liters of water Consumption Amount: 9.0 - 9.3 kg/m2 (every 1 cm thick) Brick, concrete, aerated concrete, grossconcrete, pumice block etc. of the material applied by machine. It creates a smooth surface in one coat. It saves time. It doesn't crack. It provides high strength. It is economical.

Request for a quote

ALKE MACHINERY ENGINEERING

Turkey

Using our equipment for chocolate production you can ; To produce a wide range of chocolate types in an one production line, Chocolate production in different colors and shapes, switch quickly from one product to another, To expand the diversity of the masses with each other and with wafer, cookies and other combinations by increasing the variety of forms, making filling and confectionery,Any mass can be used: chocolate, caramel, praline masses, nougat, halva, marzipan, dried fruits, fondant, soufflé, marmalade etc. Almost completely free from manual labor.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ALFA BREAD

Turkey

all line is made of food-grade materials - the machines gained ISO and CE certificates - 0ne year warranty- it works by gas or diesel - it is fully automatic. - it works by the pneumatic system - the oven withstands high temperatures. ability to fit big and medium places. our engineers are ready to plan your place.

Request for a quote

ALFA BREAD

Turkey

all line is made of food-grade materials - the machines gained ISO and CE certificates - 0ne year warranty- it works by gas or diesel - it is fully automatic. - it works by the pneumatic system - the oven works by the infrared system and it withstands high temperatures. ability to fit big and medium places. our engineers are ready to plan your place.

Request for a quote

ALFA BREAD

Turkey

all line is made of food-grade materials - the machines gained ISO and CE certificates - 0ne year warranty- it works by gas or diesel - it is fully automatic. - it works by the pneumatic system - the oven works by the infrared system and it withstands high temperatures. ability to fit big and medium places. our engineers are ready to plan your place.

Request for a quote

ALFA BREAD

Turkey

all line is made of food-grade materials - the machines gained ISO and CE certificates - 0ne year warranty- it works by gas or diesel - it is fully automatic. - it works by the pneumatic system - the oven works by the infrared system and it withstands high temperatures. ability to fit big and medium places. our engineers are ready to plan your place.

Request for a quote

ALFA BREAD

Turkey

all line is made of food-grade materials - the machines gained ISO and CE certificates - 0ne year warranty- it works by gas or diesel - it is fully automatic. - it works by the pneumatic system - the oven withstands high temperatures. ability to fit big and medium places. our engineers are ready to plan your place.

Request for a quote

ILLIYYUN SAV. OTO. DAN. LTD.

Turkey

Washing Machine Control Products Pro Test Washer Test Sonicontrol PLS Test Hemo Test Cannula Control

Request for a quote

DORU MAKINA VE DIS TICARET

Turkey

POWER SD 5 READY PLASTERING MACHINE Technical Specifications Machine Type: POWER SD 5 High quality mixing Easily disassembled and transported High quality electrical panel application 2 years warranty period – Delivery export value package type. Technical Data Power Supply 380 V - 50 Hz Motor Power 5.5 kW Compressor Capacity 250 liters/min - 5.5 bar Carrying Capacity * 5-40 liters/min (These values may vary depending on the material used, the pumping height, the consistency of the pumped material, the type of pump, rotor and stator.) Water pump 50 liters/min - 0.75kW Transport Distance Horizontal * 40 meters (Standard – if needed this will be long - option) Transport Distance Vertical * 30 meters (Standard – if needed this will be long - option) Reservoir Volume 130 liters Maximum Weight 285 kg

Request for a quote

STK MAKINA

Turkey

Iced Water Unit, Ice Bank or Chiller Unit are used to cool milk and food products. The machine has a cooling system and the tank has water inside it, the cooling groups cool water until 1-2 C and cold water is used to cool milk, dairy products and the other food products.

Request for a quote

HII

Turkey

Sandwich panel press Sandwich Panel Production Line Our contionuous PUR / PIR sandwich panel production line is already recognized its value by exporting to European country with CE and other major sandwich panel producing companies at domestic and foreign, DMMET, we will keep trying for development in accordance with customer’s needs for the high quality sandwich panels. APPLICATION of the PU-PIR PANEL PRODUCTION LINE This production line is suitable for manufacturing socket type ( wall plate panel ) and lapped type ( roof tile panel ) pu sandwich panels. FLOW CHART Uncoiler - Feeding Guide - Protective Film Coating - Roll Forming Machine - Rolling Conveyer - Steel Pre-Heating - Foaming Machine - Double Belt Pressing Machine - Rolling Conveyer - Auto Fly Cutting To Length - Runout Table - Auto Vacuum Stacker - Auto Packing Machine MAIN TECHNICAL DATAS Production Type : Continuous and automatic production Specification of Metarial : 0.3 - 0.

Request for a quote

ATMOSFER MACHINERY

Turkey

The smart production line for Diesel refers to an advanced manufacturing system that utilizes automation, digital technologies, and data analytics to optimize DEF’s production process, such as AdBlue®. DEF is a solution used in selective catalytic reduction (SCR) systems in diesel engines to reduce harmful nitrogen oxide (NOx) emissions.

Request for a quote

ZIM MÜHENDISLIK CONCRETE MACHINES

Turkey

Our ZIM 820 machine is a mid-entry machine designed for the production of double-layer paving stones. The ZIM 820 stands out with its low energy consumption, wide choice of production and high return on investment. It can be used manually, semi-automatically and fully automatically if requested. Our machine, which can produce 8 concrete blocks or 20 concrete paverstones in one press, is designed to produce 1000 pallets per day. To facilitate this production and increase quality; It has many features such as internal shaking system in the mortar cart, driver-controlled vibration system, special balancing system on the upper mold, and a specially designed vibration table. We are using “ FULLDRIVE ” frequency controlled vibration systems in our machine. This helps the life cycle of vibration engines and also decreases the total electrical consumption of vibrators.

Request for a quote

ZIM MÜHENDISLIK CONCRETE MACHINES

Turkey

ZIM T 1220 machine is designed to produce pipes. It uses forklifts to transport concrete pipes and it makes the production cycle shorter. Also it has uniqe specifications to increase production capacity, using life, products quality. This machine can produce pipes 300mm – 1200mm diameter and 1000mm – 2000mm height. The machine can be designed for producing single, double and triple pipe in a press. The vibration system of machine is controlled by frequency driver controll system. It does not need any mechanic settings. It can easily adjusted from operator pannel. The vibration system specially designed by our R&D team is used in our machines. The cooling of the vibrators are done by oil cycle system. There is a special unit for that cycling process. Oil flow is controlled by special sensors. Thanks to this technology our machines which have been working for many years without any problems, stand out with their low operating costs.

Request for a quoteResults for

Production of machines - Import exportNumber of results

42 ProductsCountries

Company type

Category

- Bakery - machinery and equipment (4)

- Napkins, paper (4)

- Machine tools - metal machining (3)

- Bakery - machinery and equipment (2)

- Industrial robots (2)

- Oils, cooking - machinery and equipment (2)

- Plastic products for engineering (2)

- Toilet paper (2)

- Confectionery - machinery and equipment (1)

- Agglomeration and emulsification machines for the food processing industry (1)

- Brick-making - machinery and equipment (1)

- Cocoa and chocolate - machines and equipment (1)

- Construction - Machines & Equipment (1)

- Food Processing (1)

- Accumulators and batteries (1)

- Bakery ovens (1)

- Blades for saws and cutting machines (1)

- Buildings, modular (1)

- Chemical industry - machinery and equipment (1)

- Concrete mixers (1)