- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- processing of stainless steel

Results for

Processing of stainless steel - Import export

ROTA MACHINERY MANUFACTURING CONTRACTING

Turkey

Stainless steel operations need a well-experienced team and new technologies to process. We have been operating precious metals for more than 20 years.

Request for a quote

NOVELTY STEEL

Turkey

Process skids are workshop assembled, modular units containing a process system or part of a process system that are used in various industries.

Request for a quote

NOVELTY STEEL

Turkey

Stainless steel is a very common material to use in fabrication projects, thanks to its versatility and durability, among others. Stainless steel possesses high good corrosion resistance which makes it the primary option for industries such as pharmaceuticals, food, petrochemicals and machinery.The versatility of stainless steel requires different fabricating techniques. Stainless steel is a sensitive material which requires delicate weld preparation practices such as thorough surface preparation prior to commencement of welding. Shoddy surface cleaning may compromise the material features such as corrosion resistance. Stainless steel has definite advantages over other metals and, it’s one of the most expensive metal. This high cost puts additional pressure on fabricators to be more careful in fabrication processes. Stainless steel should be fabricated in a specialized clean workshop to prevent contamination. Also it required specialist steel contractors

Request for a quote

ADVANCED ENGINEERING WEDGE WIRE

Turkey

The basket screen consists of cylindrical and tubular wedge wire screen which is suitable for centrifugal applications. Therefore, the conical or tubular shape of the screen basket helps the filtration process complete accurately. Centrifugal screen provides efficient filtration for unique applications with conical geometry. Advantages 1-Special surface treatment 2-Centrifugal customizable basket design 3-Corrosion resistance 4-Durable and long service life 5-Precise filtration 6-Strong mechanical properties Applications 1-Different applications are possible for the wedge wire screen basket such as vibratory centrifuge applications. 2-Mining Applications 3-Water Treatment 4-Chemical Fertilization 5-Food Processing Stainless steel with different grades and different materials can be used. Also, Special surface treatments are available for your application.

Request for a quote

ADVANCED ENGINEERING WEDGE WIRE

Turkey

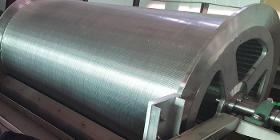

The rotary screen is a portable cylindrical wedge wire screen that can be used for filtration. Rotary screens are also called drum screen, operates with rotational movement. Drum screen filters using the open gap between the V-wires of the cylindrical wedge wire screen. Rotary drum screen is most effective for water filtration applications. Therefore, it is called rotary screen wastewater as well. With the rotation around the cylindrical axis, efficient filtration is achieved with the drum screen. Rotary screen is easy to use and easy to clean compared to the other wedge wire types Advantages 1-Special surface treatment 2-Portable customizable design 3-Corrosion resistance 4-Efficient filtration Applications 1-Water Treatment 2-Water intake 3-Food processing 4-Mineral processing Stainless steel with different grades and different materials can be used. Also, Special surface treatments are available for your application.

Request for a quote

ADVANCED ENGINEERING WEDGE WIRE

Turkey

The basket screen consists of cylindrical and tubular wedge wire screen which is suitable for centrifugal applications. Therefore, the conical or tubular shape of the screen basket helps the filtration process complete accurately. Centrifugal screen provides efficient filtration for unique applications with conical geometry. Thus, centrifugal wedge wire screen is suitable for the different kinds of applications where accurate filtration is required. Advantages Special surface treatment Centrifugal customizable basket design Corrosion resistance Durable and long service life Precise filtration Strong mechanical properties Applications Different applications are possible for the wedge wire screen basket such as vibratory centrifuge applications. Mining Applications Water Treatment Chemical Fertilization Food Processing Stainless steel with different grades and different materials can be used. Also, Special surface treatments are available for your application.

Request for a quote

ADVANCED ENGINEERING WEDGE WIRE

Turkey

The rotary screen is a portable cylindrical wedge wire screen that can be used for filtration. Rotary screens are also called drum screen, operates with rotational movement. Drum screen filters using the open gap between the Vwires of the cylindrical wedge wire screen. Rotary drum screen is most effective for water filtration applications. Therefore, it is called rotary screen wastewater as well. With the rotation around the cylindrical axis, efficient filtration is achieved with the drum screen. Rotary screen is easytouse and easy to clean compared to the other wedge wire types Advantages: Special surface treatment Portable customizable design Corrosion resistance Efficient filtration Suited for many applications Applications: Water Treatment Water intake Food processing Mineral processing Stainless steel with different grades and different materials can be used. Also, Special surface treatments are available for your application.

Request for a quote

ADVANCED ENGINEERING WEDGE WIRE

Turkey

The gap between the looped wires defines the filtration performance of the welded wedge wire screen. Welded wedge wires are used as a filter to eliminate bigger sizes or types of materials above the wedge wire screen. Special manufacturing is required to create equal loops between the welded wires. Welded wedge wire screen is used in heavy applications for high filtration performance. Advantages 1-Special surface treatment 2-Modular and customizable design 3-High durability 4-Suitable for heavy applications 5-Superior filtering with unique screen 6-Long service life & less maintenance Applications 1-Coal and Gold Mining Filtration 2-Mineral Processing 3-Water Treatment 4-Petrochemical Applications 5-Food Processing Stainless steel with different grades and different materials can be used. Also, special surface treatments are available for your application.

Request for a quote

ADVANCED ENGINEERING WEDGE WIRE

Turkey

The gap between the looped wires defines the filtration performance of the welded wedge wire screen. Welded wedge wires are used as a filter to eliminate bigger sizes or types of materials above the wedge wire screen. Special manufacturing is required to create equal loops between the welded wires. Welded wedge wire screen is used in heavy applications for high filtration performance. The main advantages of welded filter screen are Advantages Special surface treatment Modular and customizable design High durability Suitable for heavy applications Superior filtering with unique screen Long service life & less maintenance Looped wedge wire screen is adaptable for many applications including Applications Coal and Gold Mining Filtration Mineral Processing Water Treatment Petrochemical Applications Food Processing Stainless steel with different grades and different materials can be used. Also, special surface treatments are available for your application.

Request for a quote

ADVANCED ENGINEERING WEDGE WIRE

Turkey

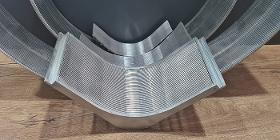

The sieve bend screen – also called bend screen – comprises a curved screen for filtration. The bend screen filters by guiding the particles along with the curved sieve filter screen. The shape of the sieve bend screen offers high filtration because of the forces exerted from the particles in the flow over the sieve bend. Thus, it is used for different applications by benefiting from the bend screen geometry. Advantages: High filtration performance Customized bend screen design Corrosion resistance Durable – long service life Precise open gap High capacity compared to panel wedge wire screen Applications With the advantages of the bend screen geometry, they are used in different applications as a filtering element. Mining process Water treatment Food processing Particle filtration Coal removal Stainless steel with different grades and different materials can be used. Also, Special surface treatments are available for your application.

Request for a quote

HPM HIJYEN PROSES MAKINALARI

Turkey

Solution preparation systems and manufacturing vessels are the starting point of the production process. We produce Solution preparation mixer to provide efficient operation and desired Solution properties.

Request for a quote

HPM HIJYEN PROSES MAKINALARI

Turkey

HGX-103 provides brushing for shoe sole, hand washing, hand drying and hand disinfection processes . It is designed to be highly reliable rigid-robust. In general, it is produced with double-hand disinfectant turnstile access control, automatic sensor liquid soap dispenser, process monitoring with PLC system, stainless steel disinfectant sprayer nozzles, adjustable height, anti-scratch plastic feet, brush and hygienic mat in the chemical pool for boots, and all in stainless steel material.

Request for a quote

ANKARA BRONZ

Turkey

It is the quality with the best malleability feature among the austenitics. Its malleability capability is around 78% and it is named as the automat of stainless steel. Although the sulfur (S) addition improves its malleability, it also reduces corrosion resistance (lower than 304) and weakens its formability, it is especially not suitable for straight bending. Despite sulfur, its toughness degree is the same as 304.

Request for a quote

ANKARA BRONZ

Turkey

It is the quality with the best malleability feature among the austenitics. Its malleability capability is around 78% and it is named as the automat of stainless steel. Although the sulfur (S) addition improves its malleability, it also reduces corrosion resistance (lower than 304) and weakens its formability, it is especially not suitable for straight bending. Despite sulfur, its toughness degree is the same as 304.

Request for a quote

3AS STAINLESS STEEL C.J.S.C.

Turkey

-COILS GRADE: AISI 303 / 304 / 304L / 316 / 316L / 316TI / 310 / 310S / 321 /430 MEASUREMENT: THICKNESS : 0.40 mm - 6 mm WIDTH: 350 mm - 1600 mm FINISH: 2B, BA, 3N, 4N, 5N, SCOTCH BRITE, HAIRLINE, DUPLO - NARROW COILS GRADE: AISI 303 / 304 / 304L / 316 / 316L / 316TI / 310 / 310S / 321 /430 MEASUREMENT: THICKNESS : 0.30 mm - 3 mm WIDTH: 210 mm - 900 mm FINISH: 2B, BA, 3N, 4N, 5N, SCOTCH BRITE, HAIRLINE, DUPLO - STRIP COILS GRADE: AISI 303 / 304 / 304L / 316 / 316L / 316TI / 310 / 310S / 321 / 430 MEASUREMENT: THICKNESS: 0.30 mm – 3 mm WIDTH: 10 mm - 210 mm FINISH: 2B, BA, 3N, 4N, 5N, SCOTCH BRITE, HAIRLINE, DUPLO

Request for a quote

NEELAM FORGE

Turkey

Neelam Forge is one of the biggest exporter, maker and provider of Monel 400 Flanges in India. We are taking into account give our customers an exceptionally subjective scope of Monel Flanges that are created utilizing quality crude material and are accessible in different evaluations and measurements.

Request for a quote

NEELAM FORGE

Turkey

Neelam Forge is one of the main Manufacturer, Supplier and Exporter of UNS NO S 31803 Flanges that are really made from Best Quality of Standard Raw Materials and are outlined according to with national and global norms. UNS S31803 Flanges is exceptionally appropriate to a great deal of mechanical procedures.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

NEELAM FORGE

Turkey

Neelam Forge is one of India's driving producers of excellent Stainless Steel 304 Flanges. As an acclaimed undertaking of the business, Neelam Forge is incorporated into offering an inconceivable bunch of Stainless Steel 304L Flanges as a producer, exporter, stockiest and provider to our family unit and overall clients. Stainless Steel 304L is the low carbon version of 304.

Request for a quote

RAMAZAN AYCAN SAC VE CELIK ISLEME MERKEZI SAN. VE TIC. A.S.

Turkey

Coil steel sheet is a building product obtained by cold rolling of liquid steel, which is frozen by continuous pouring, and then zinc coated by hot dipping method. The flat steel type produced in desired dimensions is highly preferred thanks to its easy processing, shaping and durability.

Request for a quote

GOKTURKLER CELIK A.S.

Turkey

Stainless steel bars / Stainless Steel rods are used in vast applications and are widely used in the various industry due to its durability and resistance to corrosion and rust. Our stock of stainles steel bars and stainless steel rods are always available in a wide range of diameters from 4 mm right up to 300 mm in lengths of up to 3 metres, 6 metres and supplied in 1.4301 (AISI 304), 1.4305 (AISI 303), 1.4404 (AISI 316L), 1.4021 (AISI 420), 1.4105 (AISI 430F) metal grades.

Request for a quote

RANFLEX METALS

Turkey

Ranflex Metals is leading Manufacturers, Supplier and Exporters of Stainless Steel 316 UNS S31600 Flanges. Our SS 316 Threaded Flanges are a budget-friendly option for small enterprises; they do not require welding and eliminate welding cost, in addition, they are dispensable in the combustible industries for being adaptable to low- pressure systems. ASME A182 SS 316 Weld Neck Flanges are resistant to carbide precipitation, they are immune to many corrosive fluids under a range of temperatures, they are used to affix pipes transporting chemical and corrosive media.

Request for a quote

RANFLEX METALS

Turkey

Ranflex Metals is one of the largest exporter, manufacturer and supplier of Stainless Steel 304L Flanges in India. These 304L SS Flanges are basically like rims that are used to strengthen the mechanical part or a means to attach a part to another part or surface. These products are known in the industry for their sturdy construction and durability.

Request for a quoteResults for

Processing of stainless steel - Import exportNumber of results

24 ProductsCountries

Company type